What is the Best Type of Sandpaper to Use on Aluminum?

Do you find yourself frustrated by sandpaper that gums up instantly when you try to smooth aluminum? It is a common problem, making what should be a simple task feel like a battle against sticky residue and worn-out abrasives. But don’t worry, I have been there too.

The best type of sandpaper for aluminum typically features an open-coat structure1 and uses aluminum oxide2 or ceramic abrasive grains, often on a durable backing like film or cloth. This combination helps prevent clogging and ensures effective material removal, crucial for achieving a smooth finish on this soft, non-ferrous metal.

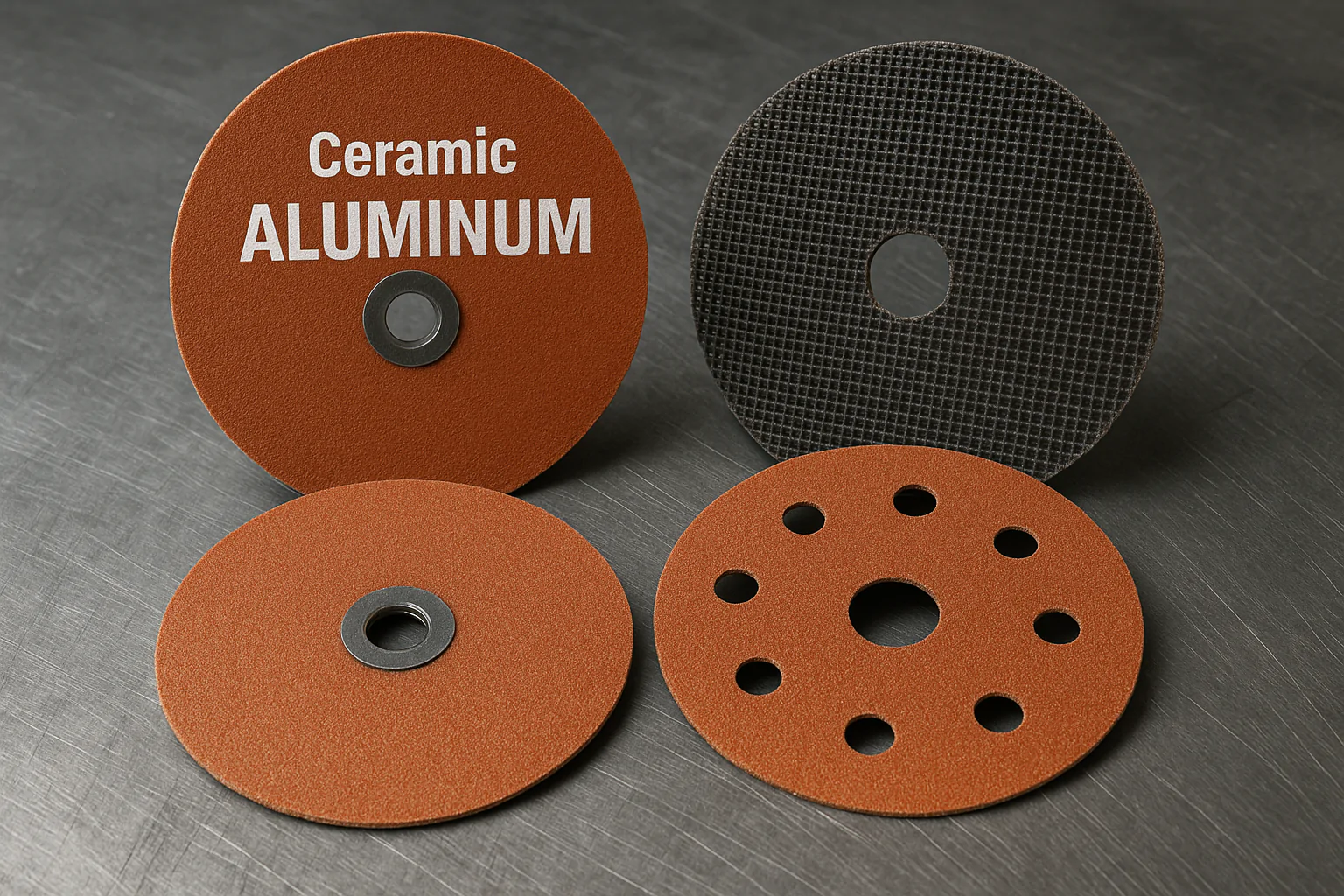

Different sandpaper types for aluminum.

Working with aluminum can be tricky because it is a soft metal and it heats up quickly. This makes standard sandpaper clog fast. Getting it right saves you time, money, and a lot of headaches. Let’s look at the options to help you choose the best abrasive for your next aluminum project.

What Kind of Sandpaper Do You Use on Aluminum?

Are you still wondering if there is a specific sandpaper that works wonders on aluminum? Many people struggle with this, and it is a valid question given aluminum’s unique properties. Getting the right abrasive makes all the difference.

When sanding aluminum, I always opt for sandpaper with a stearate coating3 and an open-coat design to resist clogging. I also look for tough abrasive grains like aluminum oxide4 or ceramic. For intricate work, film or mesh-backed discs are my go-to for their flexibility and consistent finish.

Sanding aluminum with specialized sandpaper.

When I talk to professionals in the automotive aftermarket and furniture manufacturing, a major complaint is how quickly abrasives clog and wear out when they work with aluminum. It is a constant battle. This is why I have personally focused on solutions that tackle this head-on. At NOVOGRIT, we have developed specific products to address these very issues. For example, our mesh sanding discs are designed for over 98% dust extraction. This dramatically reduces clogging. We also have film and cloth-backed products that contain self-sharpening zirconia and ceramic grains. This combination gives you much longer product life and incredibly consistent finishes. My team and I have seen our clients reduce their operational costs by 15-20% when they switch to our abrasives compared to standard ones. We backed this up with data from our Q3 2023 product trials.

When you are sanding aluminum, the type of abrasive grain is very important. Aluminum is a soft metal, so it needs specific materials to prevent the sandpaper from loading up. Here is a comparison of common abrasive grains:

Comparison of Abrasive Grains for Aluminum

| Abrasive Type | Characteristics | Best Use for Aluminum |

|---|---|---|

| Aluminum Oxide | This is the most common abrasive. It is durable and sharp, making it good for general-purpose sanding. For aluminum, it is effective, especially if it has an open-coat design and a stearate coating to resist loading. It offers a good balance of cost and performance. However, without proper anti-clogging features, it can still gum up quickly on aluminum due to the material’s softness and tendency to generate heat. The key here is the coating and open structure. Our standard aluminum oxide abrasives at NOVOGRIT integrate these features specifically for non-ferrous metals to ensure a smoother, longer-lasting operation. | Ideal for general sanding, deburring, and preparing aluminum surfaces for painting or welding. Best when used with an open-coat and stearate (anti-clog) technology to prevent premature loading. Works well for both machine and hand sanding applications where cost-effectiveness is also a factor. I’ve found it very reliable for routine metal finishing tasks. |

| Zirconia Alumina | Also known as zirconia, this abrasive is tougher and more durable than aluminum oxide. It is self-sharpening, meaning new cutting edges expose themselves as the old ones wear down. This makes it last longer and perform better under pressure, especially for heavier stock removal. On aluminum, it means less downtime changing discs and more efficient material removal without excessive heat buildup. Its robust nature makes it a prime choice for our high-performance sanding discs at NOVOGRIT, especially when we develop products for demanding industrial applications on soft metals. | Excellent for aggressive material removal, grinding, and shaping aluminum. Its self-sharpening properties make it ideal for prolonged use, such as continuous machine sanding of aluminum components. It is also a good choice for removing heavy weld seams or corrosion from aluminum surfaces. I recommend this for situations where you need significant material reduction and disc longevity. |

| Ceramic Alumina | Ceramic abrasives are the newest and most advanced. They are extremely tough and fracture in a way that keeps them sharp throughout their life, even better than zirconia. This makes them incredibly durable and effective for the most demanding applications. For aluminum, this means superior cutting performance, much longer life, and a cooler cut, which prevents the metal from deforming or discoloring due to heat. At NOVOGRIT, our high-end sanding discs leverage ceramic grains for their unmatched performance on challenging materials, including aluminum, which often sees use in high-precision parts in the automotive sector. | The top choice for heavy-duty grinding, precise shaping, and industrial applications where speed, efficiency, and abrasive life are critical. Ceramic works exceptionally well on aluminum for tasks like stock removal, blending welds, and achieving extremely consistent finishes. It excels in automated processes or on high-production lines where minimizing abrasive changes is paramount. From my experience, it delivers the most consistent and highest-quality finish on aluminum, especially when paired with our advanced backing technologies and dust extraction solutions. I personally use ceramic when I need the absolute best performance on aluminum. |

| Silicon Carbide | This abrasive is very hard and sharp, but it is also quite brittle. It fractures easily, which creates new cutting edges, making it good for very fine finishes or for preparing surfaces for polishing. However, its brittleness means it can wear down faster than other abrasives on softer metals like aluminum, especially for aggressive tasks. It shines when you need a smooth, almost polished finish. | Best for light sanding, deburring, and achieving fine finishes on aluminum, especially for aesthetic purposes or pre-polishing steps. Not recommended for heavy material removal due to its wear rate. Use it when you are aiming for a very smooth surface, similar to what you would get before a final buffing. I’ve found it effective for preparing aluminum for anodizing or clear coating, where surface uniformity is crucial. |

Open-Coat vs. Closed-Coat for Aluminum

When you pick sandpaper for aluminum, you also need to think about how the abrasive grains are spread out on the backing. This is called the "coat." There are two main types:

- Open-Coat: In open-coat sandpaper, the abrasive grains cover only about 50-70% of the surface. This leaves more space between the grains. This extra space helps prevent soft materials like aluminum from loading and gumming up the sandpaper. It allows the removed material (swarf) to clear away from the cutting surface. This means the sandpaper stays sharp longer and works more efficiently.

- Closed-Coat: Closed-coat sandpaper has abrasive grains covering 100% of the surface. This type of coating results in a more aggressive cut and a finer finish for hard materials that do not typically clog. However, for aluminum, a closed-coat abrasive will load up very quickly, becoming ineffective almost immediately. This is why I always avoid closed-coat options when working with aluminum.

What is the Best Abrasive for Aluminum?

Are you still trying to pinpoint the single best abrasive that truly excels on aluminum? It is a question that comes up often, and for good reason. Choosing the right abrasive is crucial for both efficiency and the quality of your finished product.

The best abrasive for aluminum in most demanding applications is a high-performance ceramic alumina grain5 with an open-coat structure and a film or mesh backing. This combination offers superior cutting action, clog resistance, and extended durability, crucial for effective and economical aluminum finishing6.

High-performance abrasives for aluminum.

My clients, many of whom are large hardware chain stores and automotive aftermarket companies, often ask me this exact question. They want to know what truly works best to maximize their efficiency and product life on aluminum. From my perspective, having been in the abrasives industry for 15 years and overseeing operations at NOVOGRIT where we specialize in high-performance solutions, the answer is clear: the combination of ceramic abrasive grains with an open-coat design and advanced backing materials is unbeatable for aluminum. This takes into account our direct engagement with manufacturers where we see the real-world challenges. When we are designing new products, particularly our film sanding discs and mesh sanding discs, we prioritize these features for aluminum applications. The ceramic grains offer incredible self-sharpening properties, which means consistent cutting even on soft, gummy metals. The open-coat design ensures that aluminum swarf does not build up and clog the disc prematurely. And finally, the backing material, whether it is a durable film or our innovative mesh, contributes to the overall flexibility and lifespan of the abrasive. This holistic approach is why our products often lead to significantly reduced operational costs for our partners.

Let’s dive into different types of abrasives and backings specifically optimized for aluminum work:

Types of Abrasives and Backings for Aluminum

| Abrasive Type/Backing | Details | Key Benefits for Aluminum |

|---|---|---|

| Film Sanding Discs | Film discs use a strong, polyester film as the backing material. Unlike paper, film is waterproof, tear-resistant, and provides a very uniform surface for the abrasive grains. This uniformity translates to a more even scratch pattern and a smoother finish on aluminum surfaces. The film backing also prevents curling and maintains its shape, even with heat buildup. At NOVOGRIT, our film sanding discs are engineered with premium abrasive grains like ceramic or zirconia, combined with an anti-clog coating specifically to tackle aluminum and other non-ferrous metals. The durability of the film also means these discs last significantly longer than paper-backed options, which means less time spent changing discs and more consistent output for our customers in high-volume settings. This durability also makes them ideal for wet sanding applications, which can further reduce heat and loading when working with aluminum. | Durability: Far more durable than paper, resisting tearing and curling. Uniform Finish: Provides a consistent scratch pattern due to stable backing. Clog Resistance: Often combined with open-coat and stearate for superior clog resistance. Wet Sanding Capable: Can be used with water to reduce heat and loading. I often recommend our NOVOGRIT film discs for automotive body shops working on aluminum panels, where a flawless finish and long disc life are critical. |

| Mesh Sanding Discs | Mesh discs are a revolutionary type of abrasive where the entire disc is a porous mesh, allowing for truly exceptional dust extraction. This design practically eliminates clogging, especially when sanding soft metals like aluminum. When paired with a dust extraction system, mesh discs offer over 98% dust collection efficiency. This means the abrasive surface stays clean and sharp for much longer. The reduced dust also means a healthier work environment and less cleanup. At NOVOGRIT, our mesh sanding discs are a cornerstone of our innovation. They are specifically designed to maximize efficiency and minimize clogging on challenging materials like aluminum, leading to extended service life and consistent performance. This translates directly to increased productivity and cost savings for our clients. The lack of traditional dust holes means you get consistent extraction regardless of how the disc is positioned on your sander, which is a huge advantage for complex aluminum components. | Superior Dust Extraction: Virtually eliminates clogging, keeping the abrasive sharp. Extended Life: Stays effective much longer due to constant debris removal. Consistent Cut: Maintains uniform abrasion across the entire surface. Cleaner Work Environment: Significantly reduces airborne dust. These discs are a game-changer for aluminum because they solve the loading problem almost entirely. Our NOVOGRIT mesh discs are particularly popular with furniture manufacturers who deal with aluminum frames and fittings, requiring a clean and precise finish. |

| High-Quality Sanding Discs | These are generally premium discs that incorporate advanced technologies, often combining features like ceramic or zirconia grains, open-coat designs, stearate coatings, and reinforced backings (like film or heavy-duty cloth). They are manufactured to tighter tolerances and use higher-grade adhesives and resin bonds to ensure grain retention and uniform performance. For aluminum, a "high-quality" disc means it will resist heat buildup, maintain its cutting edge, and not shed grains prematurely. It also means consistent performance from disc to disc, reducing variability in your finishing process. My focus at NOVOGRIT is always on producing high-quality sanding discs that exceed industry standards, especially for difficult materials like aluminum, where standard abrasives often fall short. We conduct rigorous testing to ensure our discs perform consistently in real-world scenarios, meeting the demands of high-production environments. | Optimal Performance: Combines superior abrasive grains with advanced backing and coatings. Longevity: Designed for extended life and consistent performance. Reliability: Reduced chance of premature wear or ineffective cutting. Application Versatility: Suitable for diverse tasks from heavy stock removal to fine finishing on aluminum. When clients ask for the absolute best for aluminum, I point them to our high-quality NOVOGRIT discs because they deliver on all fronts: speed, finish, and durability. |

| High-End Abrasive Cloth & Belts | Abrasive cloth is a very durable backing, typically made of cotton or polyester. It is much more flexible and tear-resistant than paper, making it ideal for belts, rolls, and discs used in aggressive applications or on contoured surfaces. For aluminum, cloth-backed abrasives, especially belts, are excellent for heavy grinding, deburring, and shaping because they can withstand significant pressure and heat. When combined with zirconia or ceramic grains and an open-coat, they provide excellent material removal without excessive loading. Our NOVOGRIT abrasive cloth and belts are designed for industrial-level performance, which is why they are a top choice for manufacturers dealing with large aluminum components or continuous production lines where durability and consistent cut are non-negotiable. The flexibility of cloth also allows it to conform better to complex shapes than rigid discs. | Extreme Durability: Highly resistant to tearing and breaking, even under heavy use. Flexibility: Great for contoured surfaces and machine applications like belts. Aggressive Cutting: Ideal for heavy stock removal and grinding on aluminum. Heat Resistance: Better handles heat generated during intense grinding. I recommend our NOVOGRIT abrasive cloth products for clients involved in fabricating aluminum parts or for industrial grinding operations where a robust and long-lasting abrasive is essential. |

Can Aluminum Be Sanded?

Have you ever wondered if it is even possible to sand aluminum effectively without destroying your sandpaper or getting a messy result? Many people think aluminum is too soft or sticky to sand properly, leading to frustration.

Yes, aluminum can definitely be sanded, but it requires the right approach and specific types of abrasives to avoid clogging and achieve a smooth finish. Using open-coat sandpaper7 with aluminum oxide8, zirconia, or ceramic grains and proper dust extraction is key to success on this metal.

Smoothly sanded aluminum surface.

One of my earliest experiences with aluminum involved a small home project, and I remember vividly how frustrating it was. The sandpaper would gum up immediately, turning a simple task into a sticky nightmare. It felt like I was just smearing the aluminum around instead of removing material. That is when I learned the hard way that aluminum needs a different kind of attention. This personal experience fueled my understanding of why proper abrasives are so crucial. It’s not just about the grit; it is about the entire abrasive system. The issues of clogging and premature wear are not just minor inconveniences; they are major factors that affect productivity and cost for both DIY enthusiasts and large-scale manufacturers. That is why at NOVOGRIT, our R&D team spends so much time innovating around these challenges. We focus on creating products that don’t just work on aluminum but excel, making the process smooth and efficient.

When sanding aluminum, it boils down to two main challenges: heat and clogging. Aluminum is a great conductor of heat, which means friction from sanding can quickly raise its temperature. This, combined with its relative softness, makes the metal gummy and prone to sticking to the abrasive grains. If the sandpaper loads up with aluminum particles, it stops cutting and starts rubbing, leading to even more heat and poor results. This is where the open-coat design and specialized coatings on abrasives like those from NOVOGRIT really come into play. The open spacing allows the aluminum swarf to clear away, while the stearate coating (a dry lubricant) further reduces friction and prevents sticking. It is about allowing the abrasive to cut efficiently without being hampered by the material it is trying to remove.

The type of backing also affects how well you can sand aluminum. For example, a quality film backing provides stability and prevents the abrasive from tearing or deforming under the stress of sanding. This means a more consistent cut and longer disc life. When sanding aluminum, I always recommend starting with a coarser grit to remove material quickly and then moving to progressively finer grits to refine the surface. Adequate dust extraction is non-negotiable. If you are not pulling the aluminum particles away as you sand, they will clog even the best open-coat abrasives. Whether you are using a random orbital sander or a belt sander, connect it to a vacuum system. This not only keeps your abrasive clean but also creates a much safer and cleaner work environment. By paying attention to these factors – the right abrasive type, the proper coating, durable backing, and effective dust management – you can sand aluminum just as efficiently and effectively as any other metal.

What is the Lowest Grit That Can Be Used to Sand or Grind on Aluminum?

Are you unsure if going really low on the grit scale for aluminum is a good idea, or if it will just lead to tearing and a mess? It’s a common concern, especially since aluminum is a softer metal, making very coarse abrasives seem counterintuitive.

For aggressive material removal or severe surface defects on aluminum, you can start with a grit as low as 36 or 40. However, it is crucial to use an open-coat, specialized abrasive9 (like ceramic or zirconia10) with robust backing and significant dust extraction to prevent immediate clogging and ensure efficient cutting.

Aluminum surface grit comparison.

One time, a client in the automotive aftermarket was trying to quickly remove some heavy oxidation from aluminum rims. They started with standard 60-grit paper, and within minutes, the paper was completely loaded, and they were just burning the aluminum surface. I immediately recommended they switch to a 40-grit ceramic open-coat disc, emphasizing the importance of consistent pressure and effective dust removal. The difference was night and day. They were able to strip the oxidation much faster and without the dreaded gumming up. This taught me that it’s not just about the grit number itself, but how that grit is engineered into the abrasive product and how it is used. This kind of real-world feedback is what drives our product development at NOVOGRIT, especially for our high-quality sanding discs and high-end abrasive cloth.

Going too low in grit on aluminum without the right type of abrasive can be problematic. A standard coarse grit will likely load up instantly, leading to ineffective cutting and excessive heat. However, if you are looking to remove heavy material, repair deep scratches, or prepare aluminum for welding, a very coarse grit is sometimes necessary. The key is in choosing the right type of abrasive for that low grit. For example, a 36-grit ceramic disc designed for metal will perform drastically different from a 36-grit aluminum oxide paper meant for wood. The ceramic grains are tougher and sharper, allowing them to slice through aluminum rather than just plow into it. They also benefit from a self-sharpening action, which helps maintain cutting efficiency.

When working with very low grits on aluminum, you must manage heat and swarf effectively. Use moderate pressure and keep your tool moving to prevent heat buildup in one spot. Ensure your dust extraction system is powerful enough to remove the large amounts of material that a coarse grit will generate. If you are using a bench grinder or belt sander with low-grit belts, cooling agents or even a water drip system can help keep the aluminum cool and prevent loading. Remember that starting with a very low grit means you will have deep scratch marks. You will need to step through a series of progressively finer grits (e.g., 36, then 80, 120, 220, and so on) to achieve a smooth, refined surface. Do not skip grits, or you will find it incredibly difficult to remove the deep scratches left by the coarse abrasive. Take your time, use the right tools, and you will achieve excellent results.

Conclusion

Sanding aluminum effectively demands selecting the right abrasives. Prioritize open-coat designs with durable grains like ceramic or zirconia on film or mesh backings to prevent clogging and ensure a smooth, efficient finish. This tailored approach makes a significant difference in both results and abrasive lifespan.

-

Exploring the benefits of open-coat structure can help you choose the right sandpaper for effective sanding without clogging. ↩

-

Understanding aluminum oxide’s role in sandpaper can enhance your knowledge of material selection for metalworking projects. ↩

-

Understanding stearate coating can enhance your sanding experience by preventing clogging and improving efficiency. ↩

-

Exploring the benefits of aluminum oxide can help you choose the right abrasive for your sanding projects, ensuring better results. ↩

-

Explore this link to understand how ceramic alumina grain enhances cutting action and durability in aluminum applications. ↩

-

Discover effective techniques for aluminum finishing that can improve your project’s quality and efficiency. ↩

-

Learn about open-coat sandpaper’s unique properties and why it’s essential for sanding metals like aluminum without clogging. ↩

-

Discover the benefits of aluminum oxide in sanding, including its effectiveness and durability for achieving a smooth finish. ↩

-

Explore this link to understand how open-coat abrasives enhance efficiency and prevent clogging during material removal. ↩

-

Discover why ceramic and zirconia abrasives are preferred for aluminum work, offering durability and superior cutting performance. ↩

You may also be interested in:

What is the difference between zirconium, ceramic, and aluminum oxide abrasives?

Choosing the right abrasive can be confusing. Using the wrong one wastes time, ruins your workpiece, and costs you money. Let’s make the choice simple for you. The main difference

Best Sandpaper for Paint Removal: Grits, Types, & Tips | NOVOGRIT

What is the Best Sandpaper for Removing Paint? Are you tired of staring at chipped, peeling paint on your furniture, walls, or even your car? It's a common problem, and

Automotive Wet Sanding: Supplies, Liquids & Best Sandpaper

Automotive Wet Sanding Supplies: What Do You Really Need? Wet sanding is a crucial technique in automotive refinishing, used to achieve a flawlessly smooth surface before painting or polishing. Unlike

Best Sandpaper for Paint Removal & Grit Guide

What Is the Best Sandpaper for Removing Paint? Removing old paint can be a tedious job, but using the right sandpaper makes all the difference. It's not just about grit;

Hardwood Floor Sanding: Screen vs. Sandpaper & Best Practices

Sanding Screen vs. Sandpaper for Hardwood Floors: Which is Best? When you're tackling hardwood floor projects, choosing the right abrasive is crucial for achieving a smooth, professional finish. Both sanding

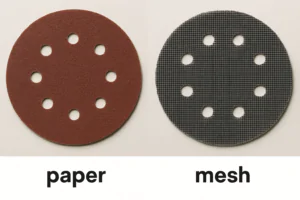

Paper Backing vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper Back vs. Mesh Sanding Discs: Which One Should You Pick? Choosing the right sanding disc backing can significantly impact your project's efficiency and finish quality. Paper-backed discs are a

Sanding Mesh vs Paper: Which is More Economical and Better?

Is Sanding Mesh More Economical Than Sandpaper? Comparing Abrasive Costs When stocking up on abrasives, cost is always a factor. Paper sandpaper has traditionally been the standard, but newer mesh

Sanding Nets & Screens Use Cases: When to Choose Mesh Abrasives

Sanding Nets and Screens: What Are Their Best Use Cases? When you encounter sanding nets or screens, you might wonder where they fit into your sanding projects. Unlike traditional solid-backed

Paper vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper vs. Mesh Sanding Discs: Which Should You Buy? Choosing the right abrasive disc is essential for efficient and effective sanding. Two primary types dominate the market: traditional paper-backed discs