Premium Mesh Abraisve Professional Dust-Free Sanding Solution

International Brand Quality, Factory Direct Price

Filter Products

Material

Color

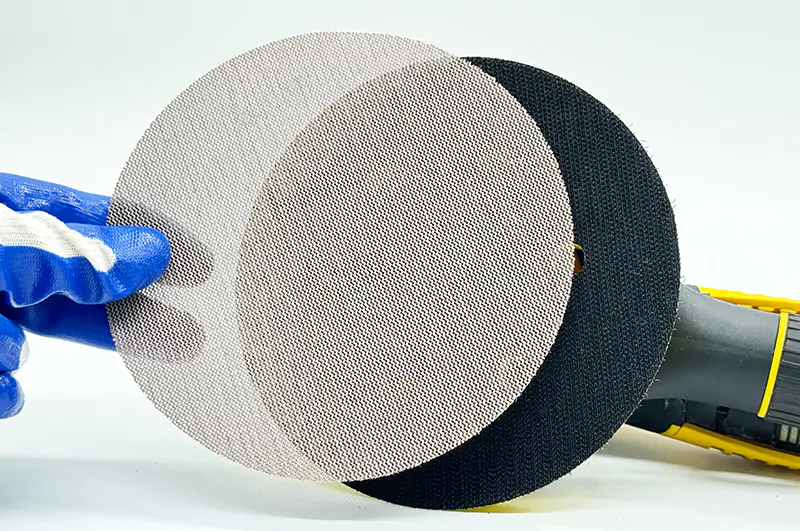

Dust-Free Sanding MA580 Mesh Disc

MA580 is A/O mesh disc with fiber backing.

Smooth repair surface

MA580 for dust-free sanding and the fiber backingstructure is durable and tough. The use of sharp and damage resistant A/O abrasives ensures higher polishing efficiency and longer lifespan, making it an ideal choice for high-quality polishing applications.Use for

SandingApplication

Polishing atomic ash, intermediate coat topcoats, and varnishes in industries such as energy, transportation, hardware, and manufacturing

Dust-Free Sanding MC590 Purple Ceramic Mesh Disc

- MC590 Ceramic Mesh Disc

- Dust-Free, Durable & High-Performance

- Self-Sharpening Ceramic Grains – Maintains cutting power by regenerating edges for long-lasting, fast, and smooth grinding.

- Advanced Ceramic Abrasives – Boosts efficiency and extends lifespan for high-demand applications.

- Dust-Free Design – Ideal for clean, precise sanding. Engineered for toughness and superior grinding results.

Use for

SandingApplication

Polishing atomic ash, intermediate coat topcoats, and varnishes in industries such as energy, transportation, hardware, manufacturing.

Why Choose Our Premium Mesh Abraisve?

Excellent dust-free grinding experience

High-quality abrasives, grinding efficiency doubled

Ultra-long life, significant savings in consumables costs

Factory-direct pricing with 15+ years of manufacturing expertise

Premium Mesh Abraisve

Professional Abrasive Solutions

20+ Years Experience

Trusted by global manufacturers and distributors since 2003, with a proven track record of excellence in abrasive solutions.

Product Description

Our Mesh Sanding Discs offer exceptional dust-free performance due to their durable fiber mesh backing. Featuring sharp, 2nd generation ceramic abrasive, they provide high efficiency and an extended lifespan. This design ensures powerful anti-clogging and effective dust extraction, resulting in reduced costs and a cleaner, safer environment.

Industry Comparison

Independent testing shows our products match or exceed international brand performance at 30-40% lower cost.

Why Choose Our Mesh Abraisve

Premium Raw Materials

Sourced from certified suppliers with strict quality control for consistent performance and durability.

Vertically Integrated

Complete control from raw material to finished product ensures quality consistency and cost efficiency.

Quality Assurance

Rigorous testing at every production stage with advanced equipment and ISO-certified processes.

Competitive Pricing

Factory-direct pricing eliminates middlemen, offering premium quality at 30-40% lower cost than international brands.

Key Features

Our professional mesh abraisve products are engineered with industry-leading technology to deliver superior performance and durability for all your sanding needs.

Premium Abrasive Grains

Engineered with aluminum oxide and ceramic grains precisely calibrated for consistent particle size distribution.

Extends product life by up to 30% compared to standard options

Advanced Backing Technology

Backing fiber mesh structure is durable and tough

Excellent dust-free grinding experience

Ultra-long life, cost savings

Super strong anti-clogging effect, reducing dust accumulation, longer service life, saving use costs

Ultimate cost performance

Precision Grit Distribution

Computer-controlled electrostatic coating ensures uniform grit distribution for consistent sanding results across the entire sheet.

Achieves flawless surface preparation with minimal effort

Dust Extraction System

Excellent dust-free grinding effect, can effectively absorb and exhaust harmful dust, reduce exposure to harmful grinding dust, thereby reducing health risks for employees and ensuring environmental safety.

Creates healthier work environments and cleaner finished surfaces

Versatile Application Range

Engineered for optimal performance across multiple substrates including wood, metal, plastic, composite materials, and automotive finishes.

Reduces inventory needs with one solution for multiple applications

Performance Comparison

See how our professional sandpaper outperforms generic alternatives across key performance metrics

| Metric | Our Professional Mesh Abaraisve | Generic Alternatives | Advantage |

|---|---|---|---|

| Material Removal Rate | High (2.5g/min) | Medium (1.2g/min) | +105% faster |

| Surface Finish Quality | Excellent (Ra 0.8μm) | Average (Ra 1.5μm) | +85% smoother |

| Dust Generation | Low | High (Standard design) | -63% less dust |

| Working Life | Extended (48+ min) | Limited 18-23 min) | +100% longer life |

| Consistency Across Sheet | Uniform (±2% variation) | Variable (±15% variation) | +650% more consistent |

Our Professional Mesh Abraisve

Generic Alternatives

Experience the Professional Difference

Our advanced Mesh Abraisve technology delivers superior results that save time, reduce material waste, and improve your finished products.

Application Scenarios

Our premium Mesh Abraisve products are engineered for optimal performance across multiple industries. Explore how our solutions can enhance your specific application needs.

Furniture Manufacturing

Specific Applications

- Fine finishing of wooden surfaces before staining or varnishing

- Removal of old finishes during furniture restoration

- Smoothing between coats of paint or lacquer

- Edge sanding for perfect joints and corners

Recommended Products

XP-Fine Film Sandpaper

Ideal for final finishing with grits 220-400

Premium Mesh Sandpaper

Perfect for dust-free sanding of wooden surfaces

Technical Tips

Pro Tip

For hardwoods like oak or maple, start with a coarser grit (120-150) and progressively move to finer grits (220-320) for the smoothest finish. Always sand in the direction of the wood grain.

Furniture Manufacturing

Specific Applications

- Fine finishing of wooden surfaces before staining or varnishing

- Removal of old finishes during furniture restoration

- Smoothing between coats of paint or lacquer

- Edge sanding for perfect joints and corners

- Surface preparation for veneer application

Recommended Products

Technical Tips

Pro Tip for Hardwoods

For hardwoods like oak or maple, start with a coarser grit (120-150) and progressively move to finer grits (220-320) for the smoothest finish. Always sand in the direction of the wood grain to avoid scratches.

Dust Management

Use our mesh sandpaper with a dust extraction system to minimize airborne particles. This not only creates a healthier work environment but also allows for better visibility of the surface being sanded.

Collision Repair Applications

Specific Applications

- Body filler sanding and shaping

- Paint removal and surface preparation

- Primer sanding between coats

- Clear coat finishing and blending

- Rust removal and metal preparation

- Plastic bumper preparation

Recommended Products

Film Series: Ideal for fine finishing and blending areas with superior dust extraction

MeshPro Series: Perfect for body filler sanding with minimal clogging

WetFlex Sheets: Designed for wet sanding clear coats and final finishing

Technical Tips

Proper Grit Progression

For optimal results, follow the proper grit progression: P80 → P120 → P180 → P240 → P320 → P400 → P600 for body work. Never skip more than one grit size to avoid visible scratches.

Dust Control

Use our mesh sandpaper with a vacuum-equipped sander to minimize dust contamination. For wet sanding, soak paper for 10-15 minutes before use for optimal flexibility and performance.

Pressure Control

Apply consistent, moderate pressure when sanding. Excessive pressure can cause premature wear and uneven surfaces. Let the abrasive do the work, especially with finer grits.

Temperature Management

Monitor surface temperature during sanding. Our XP-Film series is designed to reduce heat buildup, but pausing periodically prevents substrate damage and extends sandpaper life.

Automotive Refinishing Applications

Our premium Mesh Abrasive products are specifically engineered for automotive refinishing, delivering professional results for body shops and DIY enthusiasts alike.

Specific Applications

-

Body Filler Sanding

Perfect for leveling body filler and creating smooth transitions between repaired areas and original surfaces.

-

Paint Removal & Surface Preparation

Efficiently removes old paint and prepares surfaces for new coatings with minimal surface damage.

-

Primer Sanding

Creates the perfect foundation for paint adhesion while maintaining the integrity of the primer coat.

-

Clear Coat Finishing

Fine-grit options for removing imperfections in clear coat without causing swirl marks or haze.

Professional-grade results for automotive refinishing projects

Recommended Products

Premium Film Sanding Dsics

Waterproof film-backed sandpaper with consistent grit distribution for wet sanding applications.

Mesh Sanding Discs

Dust-free mesh sanding discs for machine sanding with excellent dust extraction capabilities.

Paper Sanding Dsics

Soft-backed sandpaper sheets for hand sanding contoured surfaces with minimal scratching.

Technical Tips

Proper Grit Progression

For optimal results, follow the proper grit progression. Never skip more than one grit level. For example, move from P320 to P400 to P600, rather than jumping directly from P320 to P600.

Wet Sanding Technique

When wet sanding, use clean water with a few drops of dish soap to reduce surface tension. Keep the surface consistently wet and rinse the sandpaper frequently to prevent clogging and ensure even results.

Machine Speed Control

When using a power sander, start with lower speeds for coarse grits and increase speed with finer grits. This prevents excessive heat buildup that can damage both the surface and the sandpaper.

Cross-Pattern Sanding

For each grit change, alter your sanding direction by 90 degrees. This helps identify areas that may have been missed in the previous grit and ensures more uniform surface preparation.

Marine Surface Polishing

Our specialized sandpaper solutions for marine environments are engineered to withstand harsh conditions while delivering superior finishing results on boats, yachts, and marine equipment.

Hull Preparation & Refinishing

- Gelcoat surface preparation before painting or coating

- Removing old paint, varnish, and anti-fouling coatings

- Smoothing fiberglass repairs and patches

- Creating uniform surfaces for new paint application

Deck & Interior Woodwork

- Teak deck restoration and maintenance

- Cabin woodwork refinishing

- Preparing surfaces for marine varnish application

- Smoothing and finishing custom marine cabinetry

Technical Tips for Marine Applications

Best Practices

- 1

Always wet sand gelcoat surfaces

Using water reduces heat buildup and prevents gelcoat crazing while extending sandpaper life.

- 2

Progress through grits systematically

Never skip more than one grit size to ensure smooth, swirl-free finishes on marine surfaces.

- 3

Use backing pads for curved surfaces

Flexible backing pads help maintain even pressure on the contoured surfaces common in boat hulls.

Grit Selection Guide

| Application | Recommended Grit |

|---|---|

| Heavy paint/coating removal | P40-P80 |

| Fiberglass preparation | P120-P180 |

| Gelcoat finishing | P320-P600 |

| Final polishing preparation | P800-P1500 |

| Teak preparation for oiling | P120-P220 |

Pro Tip: For marine applications in saltwater environments, always rinse tools and sandpaper with fresh water after use to prevent salt corrosion and extend product life.

Wall Sanding Applications

Novogrit's dust-free grinding solutions reduce your employees' exposure to harmful grinding dust. The benefits of dust-free grinding are not only improved health and reduced risks, but also increased profitability.

Specific Applications

Optimized Sanding for Walls & Surfaces

Our Mesh Abrasives are engineered for superior performance on drywall, joint compound, plaster, and painted surfaces. They offer efficient material removal, exceptional dust extraction, and a consistent, smooth finish, preparing walls perfectly for primer and paint.

Recommended Products

| Product | Type | Grit Range | Best For | Features |

|---|---|---|---|---|

| Mesh Abrasive Rolls | Mesh Cloth / Net Sandpaper | 80-600+ | Large area wall sanding, ideal with long-handle or hand tools | Efficient dust extraction, long lifespan, flexible and easy to use, versatile applications |

| Mesh Sanding Discs | Mesh Disc | 80-800+ | For use with electric/pneumatic sanders, fast and efficient sanding | Excellent dust collection, clog-resistant, uniform sanding result |

| Mesh Hand Pads / Sheets | Mesh Hand Pad / Sheet | 120-1000+ | Detailing, corner sanding, manual finishing | Ergonomic design, conforms to curves/details, washable and reusable |

Technical Tips

Progressive Grit Sequence

Always sand in sequence from coarser to finer grits. Skipping too many grits will leave scratches that are difficult to remove, affecting the final result. Ensure each step achieves the desired flatness before moving to the next grit.

Effective Dust Management

Dry sanding with Mesh Abrasives coupled with a dust extraction system is best practice for wall sanding. This significantly reduces airborne dust, protects worker health, and keeps the work area clean for easy inspection of the sanding result.

Pressure Control

Maintain consistent, moderate pressure when sanding. Excessive force not only accelerates abrasive wear but can also cause uneven wall surfaces or leave marks that are hard to remove. Let the abrasive's cutting ability do the work.

Surface Inspection

Inspect the wall surface during sanding using an inspection light (like a raking light) or by applying a guide coat. This helps identify high and low spots, pinholes, or scratches, ensuring a perfectly flat surface before applying primer.

PRO TIP: The Mesh Advantage

The open mesh structure of Mesh Abrasives allows dust to pass directly through, significantly reducing clogging and extending abrasive lifespan, especially effective for wall sanding (like joint compound) which generates a lot of dust. Using them with dust extraction equipment creates a cleaner and healthier work environment.

Application Gallery

Auto Body Sanding Process

Professional technician using our Mesh Discs for body filler shaping on a vehicle door panel.

Sanding putty and plaster

Too much dust when sanding? Switch to dust-free sanding to protect your lungs and save money.

Wall and Ceiling Sanding

Want perfect walls without the dust? Sand dust-free! Protect your health while achieving a flawless finish for painting or wallpapering.

Technical Specifications

Product Specifications

| Specification | Details |

|---|---|

| Backing Material | Film/Paper/Mesh backing with enhanced flexibility and durability |

| Grit Type and Range | Silicon Carbide, Aluminum Oxide, Zirconia,Ceramic | P40-P2000 grits available |

| Size and Format | Standard sheets: 9"×11" | Discs: 5", 6", 8" | Custom sizes available |

| Performance Metrics | Cut rate: 30% higher than industry standard | Dust extraction: 95% efficiency |

| Durability Rating | 3-5× longer lifespan compared to standard abrasives | 200+ hours continuous use |

| Temperature Resistance | Withstands temperatures up to 180°C without performance degradation |

| Water Resistance | Fully waterproof options available for wet sanding applications |

| Coating Technology | Precision electrostatic coating ensures uniform grit distribution |

Competitive Comparison

| Feature | Our Product | Industry Standard | Premium Brands |

|---|---|---|---|

| Lifespan | 98% | 80% | 98% |

| Dust Extraction | 98% | 80% | 95% |

| Grit Consistency | 95% | 85% | 98% |

| Heat Resistance | 150°C | 120°C | 150°C |

| Price Index | 100 | 80 | 200 |

Manufacturing Excellence

Our state-of-the-art production facility ensures consistent quality and precision in every sandpaper product we manufacture.

Raw Material Selection

We source premium abrasive materials and backing substrates to ensure superior performance and durability.

Precision Coating

Our advanced coating technology ensures uniform distribution of abrasive particles for consistent sanding performance.

Curing & Bonding

Our specialized curing process creates strong bonds between abrasive particles and backing material for extended product life.

Precision Cutting

Computer-controlled cutting systems ensure exact dimensions and perfect shapes for every sandpaper product.

Quality Control Checkpoints

Material Inspection

Every batch of raw materials undergoes rigorous testing for particle size, hardness, and purity before entering production.

Coating Density Analysis

Advanced imaging systems verify uniform particle distribution and optimal coating density for consistent performance.

Dimensional Verification

Laser measurement systems ensure precise dimensions and tolerances for every sandpaper sheet and disc we produce.

Rigorous Testing Procedures

Abrasion Resistance Testing

Our sandpaper undergoes accelerated wear testing to ensure it maintains consistent performance throughout its expected lifespan. We measure material removal rates and surface finish quality at regular intervals.

Velcro Tensile Test

Every batch of sandpaper, after production, is subjected to a tensile test in accordance with international standards to determine the stability of the flocking layer and to ensure that no tearing of the flocking layer is sent.

State-of-the-Art Facility

Advanced Production Lines

Our 33,000㎡ workshop houses 3 imported production lines and over 40 advanced machines, enabling a daily output of 5,000+ units with consistent quality.

Advanced R&D Laboratory

Our dedicated research facility is equipped with cutting-edge testing equipment and staffed by experienced engineers who continuously develop new formulations and manufacturing techniques.

Vertical Integration Advantages

Our complete control over the entire production process ensures superior quality, consistent performance, and competitive pricing for our customers.

Raw Material Control

We source and develop our own raw materials, ensuring consistent quality from the very beginning of the production process. This control allows us to maintain strict standards for abrasive grains, backing materials, and adhesives.

Quality Consistency

With complete control over every production stage, we maintain exceptional quality consistency across all batches. Our integrated quality control system includes 12+ inspection points throughout the manufacturing process.

Cost Efficiency

By eliminating intermediaries and controlling the entire supply chain, we significantly reduce production costs. These savings are passed directly to our customers, offering premium quality at competitive prices.

Supply Reliability

Our vertical integration ensures stable supply even during market fluctuations. With 5,000㎡ warehouse capacity and 2M+ daily production output, we maintain consistent inventory levels and meet tight delivery schedules.

Our Integrated Supply Chain Advantage

With 15 years of experience in the abrasives industry, we've built a fully integrated production ecosystem that gives us complete control from raw materials to finished products. This vertical integration is the foundation of our ability to deliver consistent quality, competitive pricing, and reliable supply.

Customization Options

Tailor our mesh abrisive products to your exact specifications with our comprehensive customization services. From size variations to private labeling, we offer flexible solutions to meet your unique requirements.

Available Variations

Size Options

- Standard: 2 - 9 inch

- Circle stripes sheets roll

- Custom dimensions available

Grit Range

- Ultra Fine: P1000-P2000

- Fine: P320-P800

- Medium: P120-P280

- Coarse: P40-P100

Backing Type

- Film backing

- Mesh backing

- Hook&Loop/PSA

- Paper backing

Packaging Options

- Retail-ready packaging

- Bulk packaging

- Individual sleeves

- Custom box designs

Tailored to Your Needs

Our advanced manufacturing facility allows for precise customization to meet your specific application requirements.

OEM Capabilities

With 15+ years of experience serving global brands, our OEM services offer complete customization from product specifications to packaging design.

Private Labeling

- Your brand on our quality products

- Custom logo printing

- Brand color matching

- Consistent brand representation

Custom Packaging

- Retail-ready packaging design

- Eco-friendly options available

- Multi-language packaging

- Barcode and SKU integration

Specification Adjustments

- Custom abrasive formulations

- Special backing materials

- Application-specific designs

- Performance optimization

Frequently Asked Questions

Find answers to common questions about our sandpaper products, ordering process, and technical specifications.

Film-backed sandpaper uses a polyester film as its backing material, providing superior tear resistance, water resistance, and flexibility compared to traditional paper-backed options. This results in longer lifespan, consistent performance on curved surfaces, and the ability to be used in wet sanding applications.

For rough sanding and material removal, start with coarse grits (40-80). For intermediate sanding, use medium grits (100-150). For finishing work, use fine grits (180-240). For ultra-smooth finishing, use very fine grits (280-600+). Always progress through grits sequentially for best results.

Yes, our film-backed and specific waterproof paper-backed sandpaper products are designed for wet sanding applications. These products are clearly marked as "waterproof" or "wet/dry" in their specifications. Wet sanding reduces dust, prevents clogging, and often provides a smoother finish.

Our standard MOQ is 1,000 pieces for regular orders. However, we offer sample packs with lower quantities (typically 50-100 pieces) for testing purposes. For OEM and custom orders, the MOQ may vary based on specifications and can be discussed during the quotation process.

You can request a quote by filling out our online form, emailing our sales team at sales@xiapu-abrasives.com, or calling us at +86-513-88755566. Please include your product specifications, quantity requirements, and delivery location for the most accurate quote. Our team typically responds within 24 hours on business days.

We accept T/T (bank transfer), L/C (Letter of Credit), and Western Union for international orders. For established customers, we offer 30% deposit with 70% balance before shipment terms. We can also accommodate other payment methods for long-term partnerships.

Yes, we offer custom sizing and shape cutting services. We can produce discs, sheets, rolls, and specialized shapes according to your specifications. Custom shapes require technical drawings and may have additional tooling costs for first-time orders. Our production team can accommodate most custom requirements with sufficient lead time.

Yes, we provide comprehensive OEM and private labeling services. We can customize packaging, print your logo on products, and adjust product specifications to meet your brand requirements. Our design team can assist with packaging design if needed. OEM orders typically require a higher MOQ of 5,000 pieces.

Standard production lead time is 15-20 days after order confirmation and deposit receipt. For large or custom orders, lead time may extend to 25-30 days. Shipping time varies by destination: 7-15 days for sea freight to most major ports, 3-5 days for air freight. We also offer express shipping options for urgent requirements.

Yes, we ship worldwide. Available shipping methods include sea freight (FCL and LCL), air freight, and express courier services (DHL, FedEx, UPS). We can arrange door-to-door delivery or ship to your designated freight forwarder. Our logistics team will recommend the most cost-effective shipping method based on your order volume and timeline.

Need Additional Support?

Technical Support

Our technical team is available to answer specific questions about product applications and performance.

Customer Service

Our customer service team is ready to assist with orders, shipping inquiries, and general questions.

Business hours: Monday-Friday, 9:00 AM - 6:00 PM (GMT+8)

Ready to Elevate Your Sanding Experience?

Partner with Xiapu Technology for premium sandpaper solutions at factory-direct prices. With 15+ years of expertise and global distribution, we're ready to meet your specific requirements.

Why Choose Xiapu Technology?

Premium Quality

International-grade materials

Reliable Delivery

On-time global shipping

Custom Solutions

Tailored to your needs

Competitive Pricing

Factory-direct advantage

Contact Us

Phone

+86-13024231188

nicola@xprazor.com