What is a Coated Abrasive? Understanding This Key Tool

If you’ve ever smoothed wood, polished metal, or prepped a surface for painting, you’ve likely used an abrasive. But abrasives come in different forms. One common type is the coated abrasive.

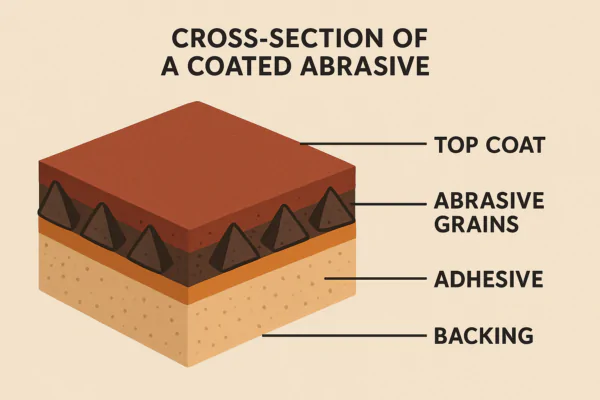

A coated abrasive consists of abrasive grains adhered to a backing material using an adhesive. Think of sandpaper or a sanding belt – these are classic examples. The abrasive grains do the cutting or grinding, the backing provides support, and the adhesive holds it all together.

Diagram showing the structure of a coated abrasive.

Understanding what makes up a coated abrasive helps you appreciate why different types perform differently and choose the right one for your specific task. It’s about more than just the grit number.

What is coated abrasive vs bonded abrasive?

Abrasives are often categorized into two main types: coated and bonded. What distinguishes these two forms, and when might you use one over the other?

The key difference between coated and bonded abrasives lies in how the abrasive grains are held together. Coated abrasives have a layer of abrasive grains glued onto a flexible backing material. Bonded abrasives, on the other hand, consist of abrasive grains mixed with and held together by a bonding agent, forming a rigid, three-dimensional shape like a grinding wheel or cutting disc.

Comparing the structure of coated and bonded abrasives.

Coated abrasives are designed for surface finishing, shaping, and material removal over a relatively flat or conforming area. The flexible backing allows the abrasive to adapt to the contours of the workpiece. They are commonly used in sheets, belts, discs, and rolls for applications like sanding wood, finishing metal, and preparing surfaces. The performance of a coated abrasive depends on the type of abrasive grain, the grit size, the density of the grain coating, and the properties of the backing and adhesive. Think of NOVOGRIT sanding discs – these are coated abrasives where high-quality grains are applied to a film or paper backing. Bonded abrasives, however, are used for heavier material removal, cutting, and grinding applications. They are rigid and maintain their shape under high forces. Examples include grinding wheels used on bench grinders or angle grinders, cutting discs for metal or masonry, and honing stones. Here, the strength of the bond holding the abrasive grains together within the matrix is crucial for performance and safety at high speeds. While both types use abrasive grains, their structure, application, and how the grains are presented to the workpiece are fundamentally different.

What are the three types of abrasive?

When we talk about abrasives in general, how are they typically classified, and what are the major categories?

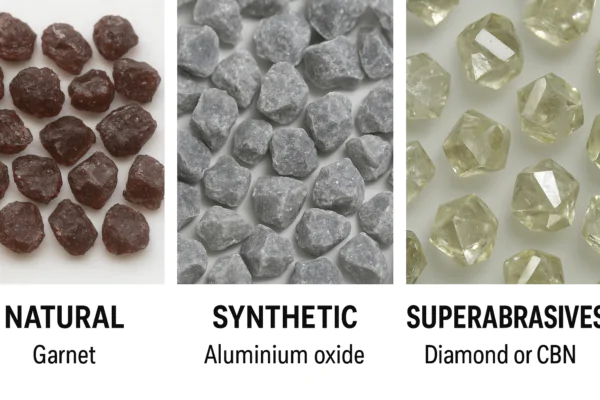

Abrasives are broadly classified into three main categories based on their origin and properties: natural abrasives, synthetic abrasives, and superabrasives. This classification reflects the hardness, sharpness, and production method of the abrasive material itself.

Different categories of abrasive materials.

Natural abrasives are minerals found in nature and used in their natural or minimally processed form. Examples include garnet, emery, flint (often used in older sandpaper), and sometimes quartz. These were historically important but are often less consistent in quality and performance compared to their synthetic counterparts. They are generally softer than synthetic abrasives. Synthetic abrasives are manufactured through chemical or thermal processes, allowing for greater control over their properties like purity, crystal shape, and size. This category includes the most common abrasives used today: aluminum oxide, silicon carbide, and ceramic aluminum oxide. Aluminum oxide is versatile and widely used for grinding metals, sanding wood, and general-purpose applications. Silicon carbide is harder and sharper, often used for grinding non-ferrous metals, ceramics, and for finishing applications. Ceramic aluminum oxide is a newer development, known for its toughness and self-sharpening properties, making it excellent for demanding applications like heavy grinding on metals. Superabrasives are the hardest known materials and are used for grinding extremely hard materials that other abrasives cannot effectively cut. The two primary superabrasives are diamond and cubic boron nitride (CBN). Diamond is the hardest material and is used for grinding carbides, ceramics, glass, and stone. CBN is the second hardest and is particularly effective for grinding ferrous metals (steel, iron) where diamond would react chemically. Most coated abrasives, including those from NOVOGRIT, utilize synthetic abrasives like aluminum oxide or silicon carbide, chosen for their consistent performance and suitability for various sanding tasks.

Is sandpaper a coated abrasive?

Sandpaper is perhaps the most familiar abrasive product to many people. Does it fit the definition of a coated abrasive?

Yes, sandpaper is a classic example of a coated abrasive. It perfectly fits the definition as it consists of abrasive grains (like aluminum oxide, silicon carbide, or even older materials like flint or garnet) that are glued or "coated" onto a flexible backing material, which is typically paper or cloth.

A close view of abrasive grains on sandpaper.

The structure of sandpaper is the defining characteristic of a coated abrasive. It starts with a backing material, which could be paper (ranging in weight and flexibility, denoted by letters like A, C, D, E, F) or cloth (cotton or polyester, offering greater durability and flexibility, often used for belts). A layer of adhesive, called the "make coat," is applied to this backing. The abrasive grains, sized according to the desired grit, are then deposited onto this adhesive layer. This is often done electrostatically, which helps orient the grains with their sharpest points facing outwards for more effective cutting. Finally, a second layer of adhesive, the "size coat," is applied over the grains to further secure them and provide durability. Different types of adhesives (like hide glue for older products, or synthetic resins like phenolic or epoxy for modern, water-resistant products) are used depending on the intended application. The type of grain, grit size, backing material, and adhesive all influence how well the sandpaper cuts, how long it lasts, and what surfaces it is suitable for. So, next time you pick up a sheet of sandpaper, you’re holding a carefully constructed coated abrasive product.

What is the difference between open and closed coated abrasives?

When looking at coated abrasives like sandpaper or sanding discs, you might notice terms like "open coat" or "closed coat." What do these terms mean, and how do they affect performance?

The difference between open and closed coated abrasives refers to the density of the abrasive grain coverage on the backing. In a closed coat abrasive, the entire surface of the backing is covered with abrasive grains. In an open coat abrasive, the grains cover only about 50-70% of the surface, leaving space between the grains.

Comparing the grain coverage on open and closed coat abrasives.

This difference in grain density significantly impacts how the abrasive performs, particularly with regards to clogging. Closed coat abrasives have more cutting points per square inch because the grains are packed tightly together. This means they can remove material faster and provide a smoother finish, especially on hard materials where clogging is less of an issue, such as metals. However, when sanding softer materials like wood, paint, or fillers, the spaces between the grains in an open coat abrasive provide room for the removed material (swarf) to accumulate without immediately clogging the abrasive surface. Clogging happens when the gaps between the abrasive grains fill up with sanding dust, preventing the sharp edges of the grains from contacting the workpiece effectively, which reduces cutting efficiency and generates heat. Therefore, open coat abrasives are generally preferred for sanding wood, paint, and other materials that produce a lot of dust or gummy residue, as they resist clogging and maintain their cutting ability for longer. Conversely, closed coat abrasives are often used for harder materials or when a very fine, smooth finish is required and clogging is less of a concern. For example, some NOVOGRIT film sanding discs are designed with specific coating densities to optimize performance on different surfaces, providing effective dust management whether the coating is more open or closed.

Conclusion

Coated abrasives are essential tools in countless applications, from DIY projects to industrial manufacturing. They consist of abrasive grains on a backing, distinct from bonded abrasives. Understanding the types of abrasive grains and coating density, like open vs. closed coat, helps you choose the right coated abrasive for efficient and effective material removal and surface finishing.

You may also be interested in:

What is the difference between zirconium, ceramic, and aluminum oxide abrasives?

Choosing the right abrasive can be confusing. Using the wrong one wastes time, ruins your workpiece, and costs you money. Let’s make the choice simple for you. The main difference

Best Sandpaper for Aluminum: NOVOGRIT's Guide to Flawless Finishes

What is the Best Type of Sandpaper to Use on Aluminum? Do you find yourself frustrated by sandpaper that gums up instantly when you try to smooth aluminum? It is

Best Sandpaper for Paint Removal: Grits, Types, & Tips | NOVOGRIT

What is the Best Sandpaper for Removing Paint? Are you tired of staring at chipped, peeling paint on your furniture, walls, or even your car? It's a common problem, and

Automotive Wet Sanding: Supplies, Liquids & Best Sandpaper

Automotive Wet Sanding Supplies: What Do You Really Need? Wet sanding is a crucial technique in automotive refinishing, used to achieve a flawlessly smooth surface before painting or polishing. Unlike

Best Sandpaper for Paint Removal & Grit Guide

What Is the Best Sandpaper for Removing Paint? Removing old paint can be a tedious job, but using the right sandpaper makes all the difference. It's not just about grit;

Hardwood Floor Sanding: Screen vs. Sandpaper & Best Practices

Sanding Screen vs. Sandpaper for Hardwood Floors: Which is Best? When you're tackling hardwood floor projects, choosing the right abrasive is crucial for achieving a smooth, professional finish. Both sanding

Paper Backing vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper Back vs. Mesh Sanding Discs: Which One Should You Pick? Choosing the right sanding disc backing can significantly impact your project's efficiency and finish quality. Paper-backed discs are a

Sanding Mesh vs Paper: Which is More Economical and Better?

Is Sanding Mesh More Economical Than Sandpaper? Comparing Abrasive Costs When stocking up on abrasives, cost is always a factor. Paper sandpaper has traditionally been the standard, but newer mesh

Sanding Nets & Screens Use Cases: When to Choose Mesh Abrasives

Sanding Nets and Screens: What Are Their Best Use Cases? When you encounter sanding nets or screens, you might wonder where they fit into your sanding projects. Unlike traditional solid-backed