Sanding Screen vs. Sandpaper: A Practical Guide to Abrasive Selection

When it comes to surface preparation, sanding is a fundamental step. But the world of abrasives offers more than just traditional sandpaper. Sanding screens present an interesting alternative. Understanding the difference is key to choosing the right abrasive for your project.

The main difference between sandpaper and sanding screens lies in their structure: sandpaper has abrasive grains bonded to a solid paper or cloth backing, while sanding screens have abrasive grains bonded to a mesh or screen material. This mesh structure allows dust to pass through, significantly reducing clogging, making sanding screens particularly effective for materials that produce a lot of fine debris, like drywall compound or wood fillers, while sandpaper is more versatile for general material removal and finishing on wood, metal, and painted surfaces.

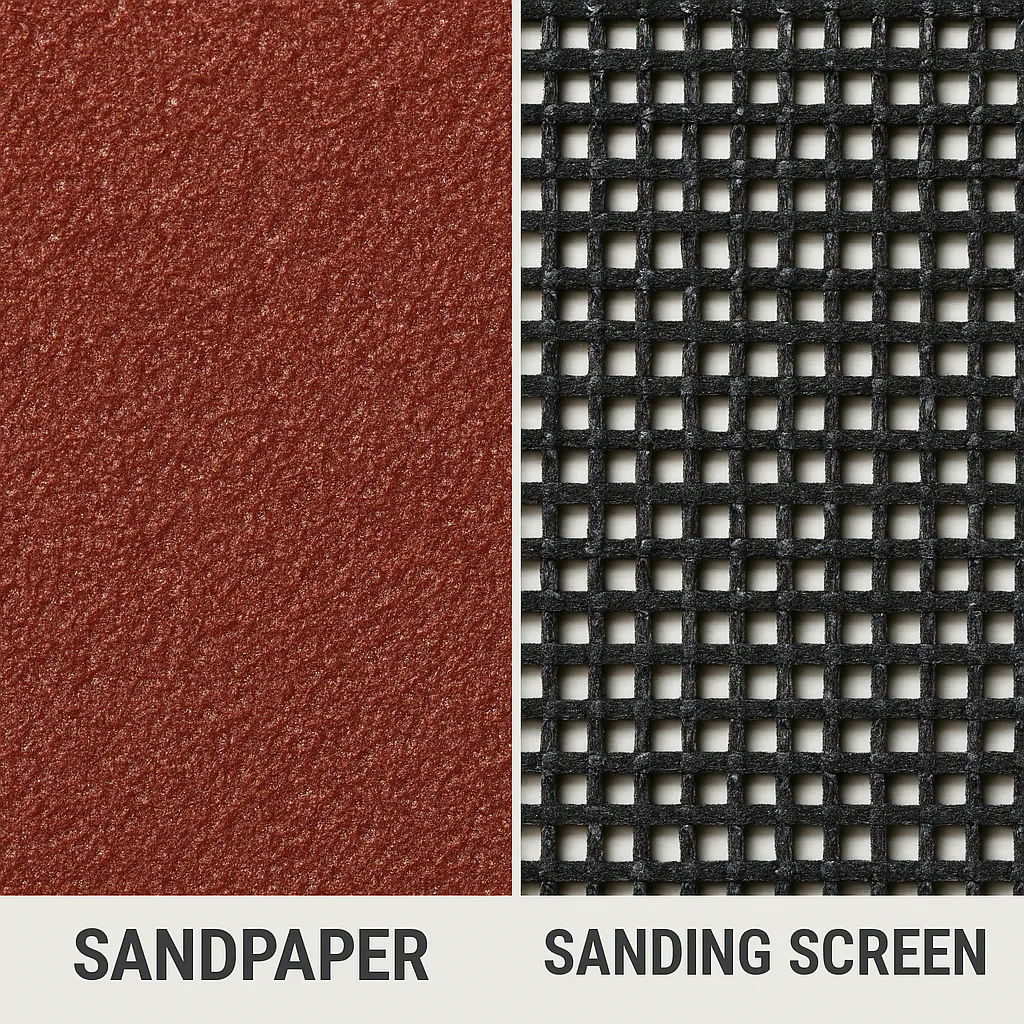

Comparing the structures of sandpaper and sanding screen.

Choosing between the two depends on the material you are working on and the desired outcome.

What is the difference between sandpaper and sanding screens?

Beyond the visual difference in structure, how does the design of sandpaper and sanding screens affect their performance and best use cases?

The fundamental difference between sandpaper and sanding screens is their backing and dust management. Sandpaper uses a solid backing (paper or cloth) which supports the abrasive but traps dust between the grains, causing clogging. Sanding screens use an open mesh backing which allows the dust to pass directly through the material and away from the abrasive surface. This prevents clogging and maintains cutting efficiency, especially on soft or dusty materials, although sandpaper generally offers more rigid support for more aggressive material removal or finer finishes.

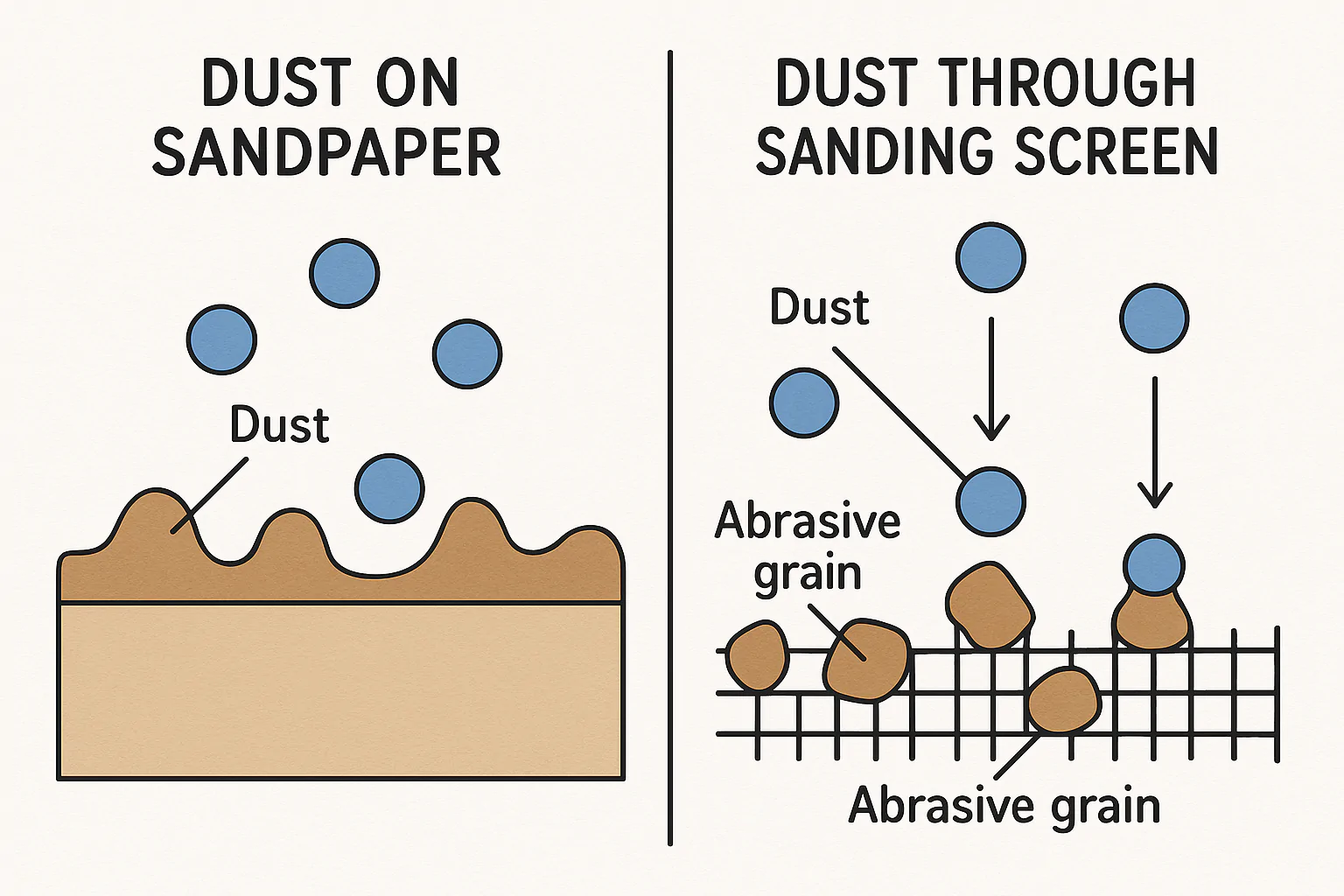

How dust affects sandpaper and sanding screens differently.

Think of it this way: traditional sandpaper is like a sheet of paper with tiny rocks glued to it. When you sand, the material you remove turns into dust. This dust has nowhere to go but to pack into the spaces between those tiny rocks (the abrasive grains). This "loading" or "clogging" reduces the sandpaper’s ability to cut, making it necessary to clean or replace the paper frequently. Sanding screens, on the other hand, are more like a rigid mesh or fabric with abrasive grains attached to the strands. The open spaces in the mesh act like tiny tunnels for the dust. As you sand, the dust goes through the mesh instead of accumulating on the surface. This means the abrasive grains stay exposed and can continue cutting effectively for much longer. This difference in dust management is significant when working with materials that produce a lot of fine, powdery dust, such as drywall joint compound, plaster, wood fillers, or even certain types of paint. Sanding screens excel in these applications because they don’t clog as quickly as sandpaper. However, the mesh structure can be less rigid than a solid sandpaper backing, which might make sandpaper feel more aggressive for initial shaping or heavy material removal on harder surfaces like bare wood or metal. Also, achieving a super fine finish, while possible with very fine mesh screens, is often easier and more consistent with the solid backing of high-grit sandpaper. Both have their place, and the best choice often depends on the specific task and material. NOVOGRIT produces various abrasive products, including different types of sanding sheets and discs, designed for optimal performance on different materials.

Is sanding mesh better than sandpaper?

It seems like sanding mesh (sanding screen) has a clear advantage regarding clogging. Does this make it universally "better" than traditional sandpaper?

Sanding mesh is not universally "better" than sandpaper; it is better suited for specific applications where clogging is a major issue, such as sanding drywall, plaster, or wood fillers, due to its open structure that allows dust to pass through. However, sandpaper offers advantages in other areas, including more aggressive material removal on harder surfaces, achieving finer finishes with high grits due to its solid backing providing more consistent contact, and often being more cost-effective for general-purpose sanding tasks on wood and painted surfaces where clogging is less severe or easily managed.

Different abrasives for different materials.

Think of it in terms of specialization. Sanding mesh is a specialist, particularly good at tackling dusty materials where clogging is a constant battle. If you’re sanding drywall seams, patching plaster, or feathering wood filler, sanding mesh will save you a lot of frustration and replacement costs because it stays effective for much longer. You can also often rinse sanding mesh to clean it and reuse it, adding to its value in these applications. However, sandpaper is the generalist. For aggressively shaping wood, sanding off old paint from a hard surface, or achieving a very smooth finish on wood or metal, traditional sandpaper often provides better performance. The solid backing gives the abrasive grains more support, allowing for more effective cutting force to be applied, which can be beneficial for material removal. Also, for very fine finishing grits (think 1000 grit and higher), the consistent, solid backing of sandpaper often allows for a more uniform scratch pattern and a smoother final surface than the slightly less rigid structure of mesh screens. Cost can also be a factor; while mesh lasts longer in specific applications, standard sandpaper can sometimes be less expensive upfront for general tasks where clogging isn’t the primary problem. High-quality abrasives from companies like NOVOGRIT are available in both traditional paper/cloth backings and mesh formats, allowing users to select the best option for their specific needs.

What would you use 60 grit sandpaper for?

Let’s talk about a specific grit level. What types of tasks are typically performed with 60 grit sandpaper?

60 grit sandpaper is considered a coarse grit and is primarily used for aggressive material removal, shaping, and smoothing very rough surfaces. Its common uses include stripping paint or varnish from wood, initial shaping of wood or other materials, removing deep scratches or imperfections, leveling uneven surfaces, and preparing heavily weathered or damaged surfaces for subsequent sanding with finer grits.

Aggressively sanding wood with 60 grit paper.

When you pick up a sheet of 60 grit sandpaper, you’re holding a tool for making big changes quickly. This isn’t the grit you use for final finishing. The abrasive particles at this grit size are relatively large and spaced far apart, allowing them to cut aggressively. If you have a piece of wood with old, flaky paint or a thick layer of varnish that needs to be stripped, 60 grit is often a good starting point. It cuts through the finish quickly. It’s also used for initial shaping, like rounding over sharp edges quickly or leveling out significant unevenness in a surface. If a surface has deep scratches, dents, or heavy weathering, 60 grit can be used to remove the damaged layer to get down to clean material. Because it removes material so quickly, it also leaves behind significant scratches itself. These deep scratches are then the target for the next, finer grit in your progression (typically 80 or 100 grit), which will remove the 60-grit scratches and leave finer ones that the following grit will address. It’s a stepped process. Using 60 grit on a surface that only needs light sanding or a fine finish will cause unnecessary work in the subsequent steps to remove the deep scratches it creates. It’s a tool for rough work and is meant to be followed by progressively finer grits to refine the surface. For aggressive sanding tasks on various materials, a durable 60 grit sandpaper from a manufacturer like NOVOGRIT, possibly with a tough backing material, will provide consistent performance.

Conclusion

Sanding screens excel at dust management for materials like drywall, while traditional sandpaper offers versatility for various tasks, including aggressive removal with grits like 60 and finer finishing. Choosing between them, and selecting the right grit, depends on the material and the desired outcome for your project.

You may also be interested in:

What is the difference between zirconium, ceramic, and aluminum oxide abrasives?

Choosing the right abrasive can be confusing. Using the wrong one wastes time, ruins your workpiece, and costs you money. Let’s make the choice simple for you. The main difference

Best Sandpaper for Aluminum: NOVOGRIT's Guide to Flawless Finishes

What is the Best Type of Sandpaper to Use on Aluminum? Do you find yourself frustrated by sandpaper that gums up instantly when you try to smooth aluminum? It is

Best Sandpaper for Paint Removal: Grits, Types, & Tips | NOVOGRIT

What is the Best Sandpaper for Removing Paint? Are you tired of staring at chipped, peeling paint on your furniture, walls, or even your car? It's a common problem, and

Automotive Wet Sanding: Supplies, Liquids & Best Sandpaper

Automotive Wet Sanding Supplies: What Do You Really Need? Wet sanding is a crucial technique in automotive refinishing, used to achieve a flawlessly smooth surface before painting or polishing. Unlike

Best Sandpaper for Paint Removal & Grit Guide

What Is the Best Sandpaper for Removing Paint? Removing old paint can be a tedious job, but using the right sandpaper makes all the difference. It's not just about grit;

Hardwood Floor Sanding: Screen vs. Sandpaper & Best Practices

Sanding Screen vs. Sandpaper for Hardwood Floors: Which is Best? When you're tackling hardwood floor projects, choosing the right abrasive is crucial for achieving a smooth, professional finish. Both sanding

Paper Backing vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper Back vs. Mesh Sanding Discs: Which One Should You Pick? Choosing the right sanding disc backing can significantly impact your project's efficiency and finish quality. Paper-backed discs are a

Sanding Mesh vs Paper: Which is More Economical and Better?

Is Sanding Mesh More Economical Than Sandpaper? Comparing Abrasive Costs When stocking up on abrasives, cost is always a factor. Paper sandpaper has traditionally been the standard, but newer mesh

Sanding Nets & Screens Use Cases: When to Choose Mesh Abrasives

Sanding Nets and Screens: What Are Their Best Use Cases? When you encounter sanding nets or screens, you might wonder where they fit into your sanding projects. Unlike traditional solid-backed