Sanding Nets and Screens: What Are Their Best Use Cases?

When you encounter sanding nets or screens, you might wonder where they fit into your sanding projects. Unlike traditional solid-backed sandpaper, these mesh abrasives offer unique advantages specifically suited for certain tasks. Knowing their strengths helps you use them most effectively.

Sanding nets, also known as sanding screens or mesh discs, are primarily used for applications where dust clogging is a significant problem, especially when sanding soft materials like drywall joint compound, plaster, wood fillers, or certain types of paint. Their open mesh structure allows dust to pass through, preventing the abrasive from becoming quickly loaded and ineffective. They are particularly effective when used with sanders that have integrated dust extraction systems.

Sanding mesh used for drywall.

These applications often benefit from the extended life and consistent performance that mesh provides.

What is sanding mesh used for?

Let’s dive deeper into the specific materials and tasks where sanding mesh truly shines and makes a difference compared to traditional sandpaper.

Sanding mesh is primarily used for sanding materials that produce large amounts of fine, powdery dust that easily clog traditional sandpaper. This includes sanding drywall joint compound and plaster to achieve smooth walls and ceilings, feathering wood fillers or putties to blend repairs seamlessly, and preparing certain painted surfaces where paint dust is prevalent. Its open structure allows dust to pass through, preventing clogging and maintaining cutting efficiency, making it ideal for use with dust collection systems for a cleaner workspace and extended abrasive life.

Sanding joint compound with mesh.

When you’re tackling a project that involves sanding drywall repairs or newly taped seams, you’ll quickly notice how fast traditional sandpaper gets clogged with the fine white dust. The abrasive grains get buried under a layer of compacted dust, and the paper stops cutting. This is where sanding mesh excels. Its woven structure provides thousands of tiny escape routes for that dust. As you sand, the dust goes through the mesh instead of sitting on the surface. This keeps the abrasive grains exposed, allowing them to continue cutting effectively for much longer. The same applies to sanding plaster surfaces or smoothing out wood fillers used to patch holes or imperfections. These materials also generate very fine, clogging dust. Using mesh significantly reduces the need to constantly clean or replace your abrasive, speeding up the work and saving money on materials in the long run. Sanding mesh is also excellent when used with power sanders connected to a vacuum or dust extractor. The vacuum pulls air (and dust) through the mesh, providing incredibly efficient dust collection right at the source. This results in a much cleaner work area and less airborne dust, which is better for your health and makes it easier to see your progress. While you can technically use mesh on wood, it’s most impactful and offers the biggest advantage over sandpaper on these dust-heavy, softer materials. For those looking for effective dust control on these specific materials, NOVOGRIT offers high-quality sanding mesh products designed for optimal performance.

What is a sanding screen used for?

Is there a difference between sanding mesh and sanding screen, or are they the same thing with different names? And what specific applications are they known for?

"Sanding screen" and "sanding mesh" generally refer to the same type of abrasive product: one with an open, woven or screened backing material instead of a solid paper or cloth. Sanding screens are widely used in the flooring industry for sanding hardwood floors between coats of finish, or for light abrasion to prepare a surface for refinishing, as the open structure prevents clogging from the finish residue or dust. They are also used in automotive repair for smoothing body filler and primer, benefiting from the excellent dust extraction capabilities.

Sanding a hardwood floor with a screen.

Essentially, "sanding mesh" and "sanding screen" are interchangeable terms describing the same type of abrasive technology. The term "screen" is particularly common in the flooring industry. Large sanding screens are used with floor buffers for a process often called "screening" or "abrading." This isn’t typically for heavy material removal but rather for scuffing or lightly sanding the existing finish on a hardwood floor between coats of polyurethane or varnish. The purpose is to create a micro-scratch pattern that the next coat of finish can adhere to, ensuring good intercoat adhesion and a durable final finish. During this process, old finish residue and fine dust are generated, and the open structure of the screen prevents it from loading up, allowing for consistent abrasion across the large floor surface. The dust is often contained within a dust skirt or collected by a vacuum system attached to the buffer. In the automotive refinishing world, sanding screens/mesh are also popular for shaping and smoothing body filler and primer. These materials also produce clogging dust, and the mesh allows for efficient sanding and dust removal, leading to a smoother surface for painting. The ability to rinse and reuse some types of sanding screens (particularly those designed for wet sanding) also adds to their value in these applications. NOVOGRIT provides different types of mesh abrasives suitable for various industrial applications, including flooring and automotive.

What is a sanding pad used for?

Moving slightly away from just the abrasive sheet itself, what is a sanding pad, and how is it used in conjunction with abrasives?

A sanding pad is a support accessory used with abrasive sheets, discs, or screens. It provides a cushioned or rigid backing that allows for even pressure distribution when sanding by hand or with a power tool. Sanding pads come in various forms, including hand-held blocks (for manual sanding), interface pads (soft foam pads placed between the sander and the abrasive disc for contour sanding), and the base pads of power sanders (which provide the surface the sanding disc attaches to, often with holes for dust extraction). Their purpose is to provide a stable, comfortable, or flexible platform for the abrasive to work effectively on the surface.

Various types of sanding pads.

Think of a sanding pad as the tool that holds and supports your abrasive while you apply pressure. The simplest form is a hand sanding block. This is a piece of rigid material, often plastic or rubber, that you wrap sandpaper around or which has a system (like clips or hook-and-loop) to attach a piece of sandpaper or a sanding sponge. Using a block provides a flat, firm surface to push the abrasive evenly against your workpiece, making it much easier to create a flat surface or maintain straight edges than just using your hand. For power sanders, the "sanding pad" is the base plate of the tool itself. This is the circular or rectangular surface that the sanding disc (either paper or mesh) attaches to, typically via a hook-and-loop system. These power tool pads often have holes drilled through them that align with corresponding holes in the abrasive disc; these holes are part of the sander’s dust collection system, allowing dust to be pulled through. An "interface pad" is a specific type of sanding pad used with power sanders. It’s a soft, usually foam, pad that goes between the power sander’s base pad and the sanding disc. Interface pads add cushioning and flexibility. This is incredibly useful when sanding curved or contoured surfaces, as the flexibility allows the abrasive to conform better to the shape. It also helps to prevent "pigtail" swirl marks, especially with random orbital sanders, by dampening vibrations and promoting more consistent contact. So, while sanding nets/screens and sandpaper do the cutting, sanding pads provide the necessary support and interface for applying pressure and controlling the sanding process, whether by hand or with a machine. NOVOGRIT produces high-quality sanding discs and related accessories like interface pads that work effectively together.

Conclusion

Sanding nets and screens are best for dusty materials like drywall and fillers, preventing clogging and improving dust collection. They are particularly useful in flooring and automotive applications. Sanding pads are supporting tools that provide the necessary backing for abrasives, aiding in even pressure application for both hand and power sanding.

You may also be interested in:

What is the difference between zirconium, ceramic, and aluminum oxide abrasives?

Choosing the right abrasive can be confusing. Using the wrong one wastes time, ruins your workpiece, and costs you money. Let’s make the choice simple for you. The main difference

Best Sandpaper for Aluminum: NOVOGRIT's Guide to Flawless Finishes

What is the Best Type of Sandpaper to Use on Aluminum? Do you find yourself frustrated by sandpaper that gums up instantly when you try to smooth aluminum? It is

Best Sandpaper for Paint Removal: Grits, Types, & Tips | NOVOGRIT

What is the Best Sandpaper for Removing Paint? Are you tired of staring at chipped, peeling paint on your furniture, walls, or even your car? It's a common problem, and

Automotive Wet Sanding: Supplies, Liquids & Best Sandpaper

Automotive Wet Sanding Supplies: What Do You Really Need? Wet sanding is a crucial technique in automotive refinishing, used to achieve a flawlessly smooth surface before painting or polishing. Unlike

Best Sandpaper for Paint Removal & Grit Guide

What Is the Best Sandpaper for Removing Paint? Removing old paint can be a tedious job, but using the right sandpaper makes all the difference. It's not just about grit;

Hardwood Floor Sanding: Screen vs. Sandpaper & Best Practices

Sanding Screen vs. Sandpaper for Hardwood Floors: Which is Best? When you're tackling hardwood floor projects, choosing the right abrasive is crucial for achieving a smooth, professional finish. Both sanding

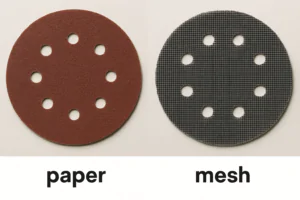

Paper Backing vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper Back vs. Mesh Sanding Discs: Which One Should You Pick? Choosing the right sanding disc backing can significantly impact your project's efficiency and finish quality. Paper-backed discs are a

Sanding Mesh vs Paper: Which is More Economical and Better?

Is Sanding Mesh More Economical Than Sandpaper? Comparing Abrasive Costs When stocking up on abrasives, cost is always a factor. Paper sandpaper has traditionally been the standard, but newer mesh

Paper vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper vs. Mesh Sanding Discs: Which Should You Buy? Choosing the right abrasive disc is essential for efficient and effective sanding. Two primary types dominate the market: traditional paper-backed discs