Is Sanding Mesh More Economical Than Sandpaper? Comparing Abrasive Costs

When stocking up on abrasives, cost is always a factor. Paper sandpaper has traditionally been the standard, but newer mesh sanding discs offer different advantages. The question is, does the potential for extended life make mesh more economical in the long run?

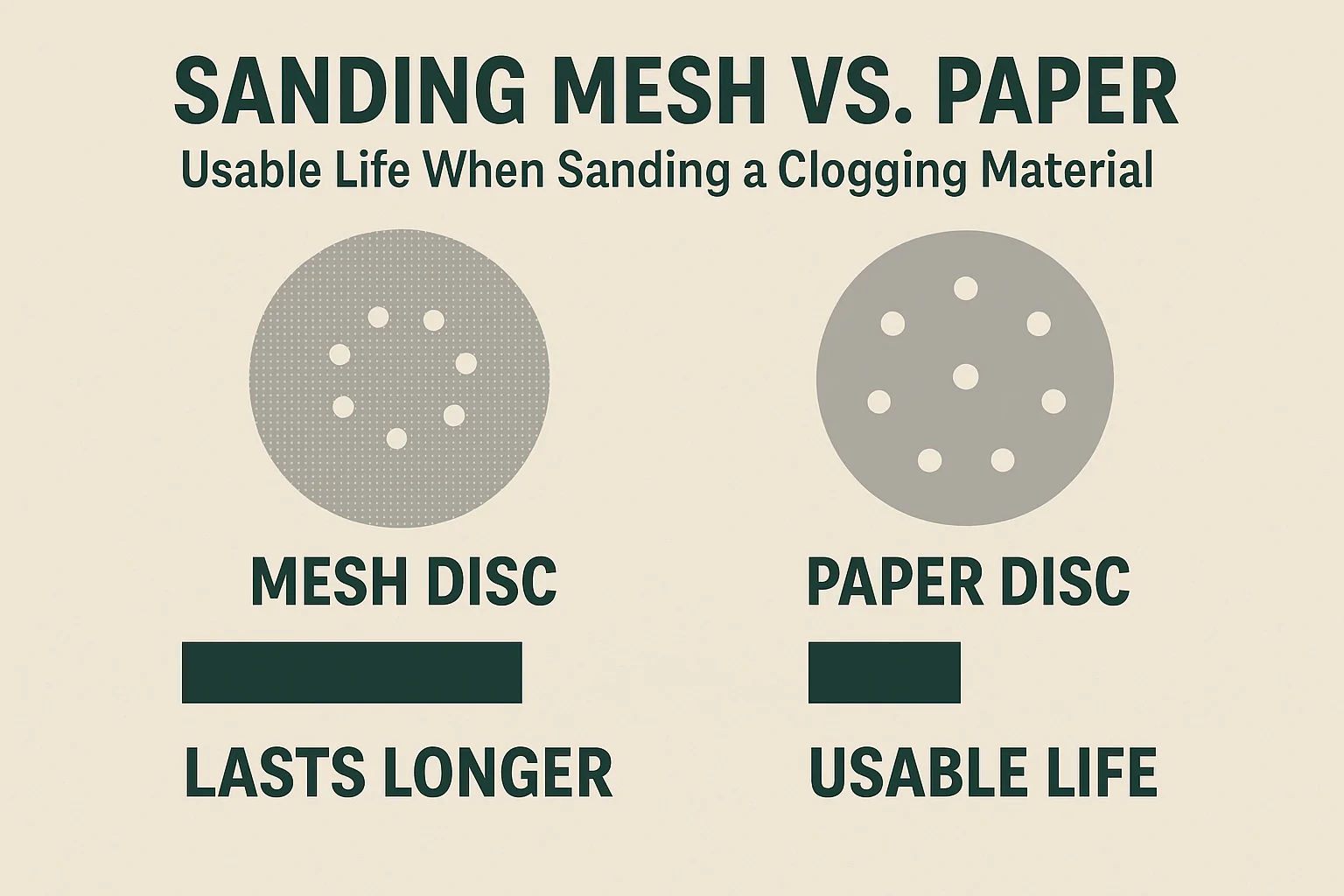

Sanding mesh can be more economical than traditional paper sandpaper in specific applications where dust clogging is a major issue, such as sanding drywall compound, wood fillers, or certain paints. While the initial purchase price per disc might be higher for mesh, its resistance to clogging allows it to cut effectively for a significantly longer time than paper discs in these conditions, ultimately requiring fewer discs to complete the same job and saving money over the project duration. However, for applications where clogging is not a primary concern or for very fine finishing, paper might still be the more cost-effective option.

Comparing the longevity of mesh and paper abrasives.

Understanding the scenarios where mesh shines is key to realizing its potential economic benefit.

Is a sanding sponge better than sandpaper?

Beyond discs and sheets, sanding sponges offer another option for smoothing surfaces. Are they better than traditional sandpaper, or do they serve a different purpose?

A sanding sponge is not inherently "better" than sandpaper; it’s a different tool optimized for different tasks. Sanding sponges are typically made of foam with abrasive grit bonded to the surfaces, offering flexibility to conform to curved, contoured, or irregular shapes that flat sandpaper struggles with. They are excellent for sanding moldings, profiles, edges, and getting into tight corners. Sandpaper, with its rigid or semi-rigid backing (paper or cloth), provides a flatter, more consistent surface for sanding large flat areas, aggressive material removal, and achieving very fine, uniform finishes, offering better control for flat work.

Differences in flexibility between sanding sponges and sandpaper.

My personal workbench always has a mix of both sanding sponges and various types of sandpaper because they are good at different things. When I’m working on something with a lot of curves, like chair legs, decorative trim, or turned spindles, a sanding sponge is my go-to. The foam backing allows the abrasive surface to follow the contours of the piece, sanding evenly across the entire curve without flattening it out or missing spots. Sandpaper, especially on a rigid block, would only touch the high points. Sanding sponges are also great for sanding edges, as the foam provides a bit of cushioning that helps prevent rounding over sharp corners unintentionally, or conversely, helps create a nice, consistent small radius on an edge. They are also useful for light scuffing between coats of finish. However, when I need to flatten a surface, remove a significant amount of material quickly, or achieve a perfectly uniform scratch pattern on a flat board, I always reach for sandpaper on a block or use a power sander with a disc. The solid backing provides the necessary rigidity to apply focused pressure and ensure the entire surface is being worked evenly. Sandpaper also typically comes in a wider range of very fine grits than sponges, which are important for final finishing steps. So, neither is strictly "better"; they are designed for different applications. Sanding sponges are for flexibility and contour work, while sandpaper is for flat surfaces, aggressive removal, and fine finishing. Many suppliers, including NOVOGRIT, offer both high-quality sandpaper and sanding sponges to cover all these sanding needs.

Is sanding mesh any good?

We touched on this when comparing mesh and paper, but let’s reiterate and provide more detail on the effectiveness and quality of sanding mesh in practical use.

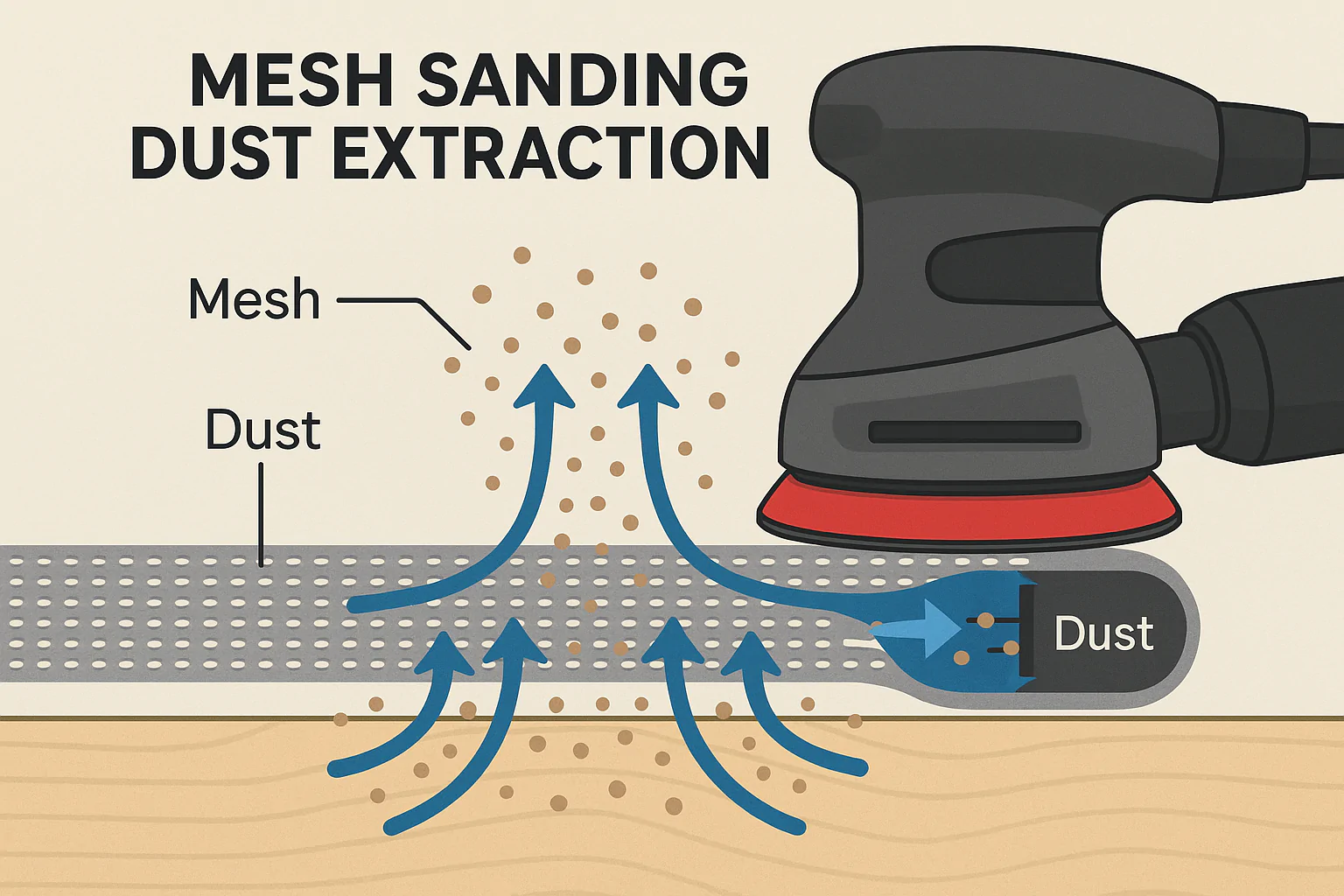

Yes, sanding mesh is very good and offers distinct advantages, making it highly effective for specific sanding tasks. Its open structure significantly reduces clogging when sanding materials like drywall compound, fillers, and paints, maintaining cutting efficiency for longer periods and extending disc life compared to traditional paper abrasives. This leads to faster work and requires fewer disc changes. When paired with dust extraction systems, mesh provides superior dust removal, resulting in a cleaner workspace and better finish visibility. It is a valuable and effective abrasive option, particularly for applications where dust management is critical.

How mesh facilitates dust extraction.

When I first started seeing mesh discs appear, I was skeptical. Would they last? Would they cut effectively? After using them extensively, especially for drywall patching and sanding painted furniture, my skepticism disappeared. They are genuinely good products for the right job. The key benefit, as mentioned, is their ability to resist clogging. On dusty materials, this isn’t just a slight improvement; it’s a dramatic difference. A paper disc might be clogged and ineffective after just a minute or two of sanding drywall mud, forcing you to stop and change it. A mesh disc, in the same situation, can keep cutting for five, ten, or even fifteen minutes before showing signs of reduced efficiency. This directly translates to less downtime and faster project completion. Furthermore, the ability to extract dust through the entire surface of the disc (when the sander’s base pad allows) leads to a much cleaner sanding experience. Less dust in the air means less cleanup, better visibility of the surface you are working on, and a healthier environment. While some very high-pressure or aggressive grinding tasks might still be better suited for certain heavy-duty paper or cloth-backed abrasives (like those with Zirconia or Ceramic grains), for most common sanding applications involving materials that produce fine, clogging dust, mesh is not just "any good" – it’s often the best tool for the job. Companies like NOVOGRIT have invested in developing high-performance mesh abrasives that utilize quality abrasive grains bonded to durable mesh backings, ensuring they are effective and long-lasting.

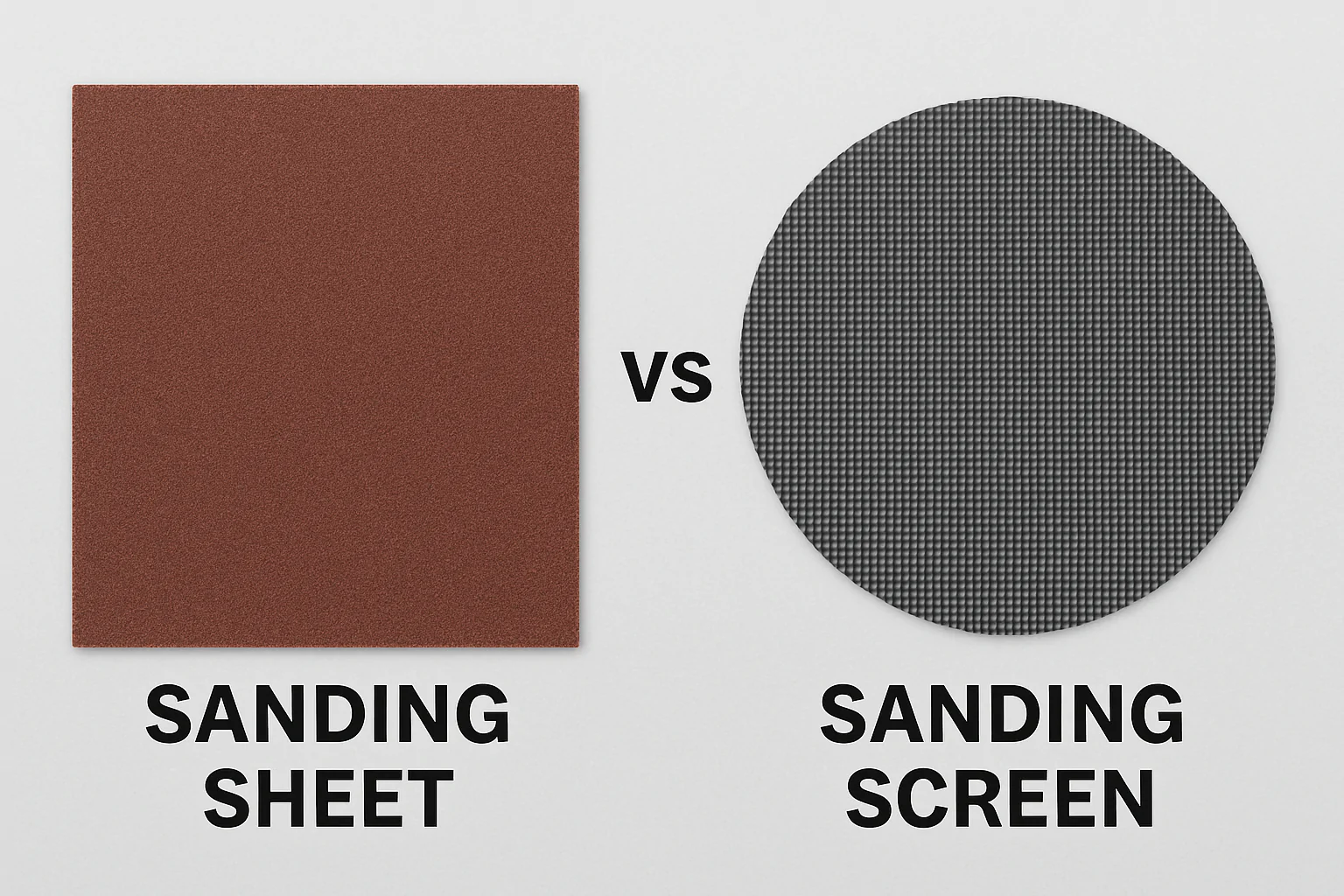

What is the difference between sanding sheets and sanding screens?

Let’s clarify the terminology. When people talk about sanding sheets and sanding screens, are they referring to the same thing, or are there distinct differences in form or function?

Sanding sheets typically refer to standard sandpaper sold in rectangular sheets, usually 9×11 inches (or similar metric sizes), designed to be used by hand with a sanding block or cut to fit smaller hand tools. The backing is traditionally paper or cloth. Sanding screens, on the other hand, specifically refer to abrasive products with an open, mesh-like structure for the backing, designed primarily to prevent dust clogging and facilitate dust extraction. While both are forms of abrasive, "sheet" usually implies the traditional solid-backed rectangular format for general hand sanding, while "screen" denotes the specific mesh type, often sold in larger discs for machine use (like floor buffers) or smaller discs/sheets for orbital sanders or hand blocks.

Comparing a standard sanding sheet and a sanding screen (disc).

The main difference is the backing material and typical format. "Sanding sheet" most often conjures the image of the familiar 9×11 inch rectangle of sandpaper you’d buy at the hardware store. You tear or cut pieces from this sheet to fit into a hand sanding block, wrap around a piece of wood, or use by hand for detail work. The backing is solid paper or cloth, coated with abrasive grains. "Sanding screen," as we’ve discussed, refers to the abrasive with the open mesh backing. While you can buy sanding mesh cut into sheet-like rectangles for hand sanding, the term "screen" is perhaps more commonly associated with the larger, circular discs used on floor buffers or orbital sanders, or smaller discs for random orbital sanders. The critical distinction is the open structure of the screen/mesh backing, which is its defining characteristic and primary benefit (dust handling), versus the solid backing of a traditional sanding sheet. So, a sanding screen is a type of abrasive product with a specific mesh backing, while a sanding sheet refers to the common rectangular format of abrasive, usually with a solid backing. NOVOGRIT manufactures both types of abrasives, understanding that each serves different purposes and preferences in the market.

Conclusion

Sanding mesh/screens can be more economical than paper sandpaper for dusty applications due to longer life and better dust control. Sanding sponges are better for curved surfaces due to their flexibility, while sandpaper excels on flat areas. "Sanding sheets" typically refer to traditional solid-backed rectangles, distinct from the open mesh structure of "sanding screens."

You may also be interested in:

What is the difference between zirconium, ceramic, and aluminum oxide abrasives?

Choosing the right abrasive can be confusing. Using the wrong one wastes time, ruins your workpiece, and costs you money. Let’s make the choice simple for you. The main difference

Best Sandpaper for Aluminum: NOVOGRIT's Guide to Flawless Finishes

What is the Best Type of Sandpaper to Use on Aluminum? Do you find yourself frustrated by sandpaper that gums up instantly when you try to smooth aluminum? It is

Best Sandpaper for Paint Removal: Grits, Types, & Tips | NOVOGRIT

What is the Best Sandpaper for Removing Paint? Are you tired of staring at chipped, peeling paint on your furniture, walls, or even your car? It's a common problem, and

Automotive Wet Sanding: Supplies, Liquids & Best Sandpaper

Automotive Wet Sanding Supplies: What Do You Really Need? Wet sanding is a crucial technique in automotive refinishing, used to achieve a flawlessly smooth surface before painting or polishing. Unlike

Best Sandpaper for Paint Removal & Grit Guide

What Is the Best Sandpaper for Removing Paint? Removing old paint can be a tedious job, but using the right sandpaper makes all the difference. It's not just about grit;

Hardwood Floor Sanding: Screen vs. Sandpaper & Best Practices

Sanding Screen vs. Sandpaper for Hardwood Floors: Which is Best? When you're tackling hardwood floor projects, choosing the right abrasive is crucial for achieving a smooth, professional finish. Both sanding

Paper Backing vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper Back vs. Mesh Sanding Discs: Which One Should You Pick? Choosing the right sanding disc backing can significantly impact your project's efficiency and finish quality. Paper-backed discs are a

Sanding Nets & Screens Use Cases: When to Choose Mesh Abrasives

Sanding Nets and Screens: What Are Their Best Use Cases? When you encounter sanding nets or screens, you might wonder where they fit into your sanding projects. Unlike traditional solid-backed

Paper vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper vs. Mesh Sanding Discs: Which Should You Buy? Choosing the right abrasive disc is essential for efficient and effective sanding. Two primary types dominate the market: traditional paper-backed discs