Paper Back vs. Mesh Sanding Discs: Which One Should You Pick?

Choosing the right sanding disc backing can significantly impact your project’s efficiency and finish quality. Paper-backed discs are a traditional staple, while mesh discs represent a newer technology focused on dust control. How do you decide which is right for your work?

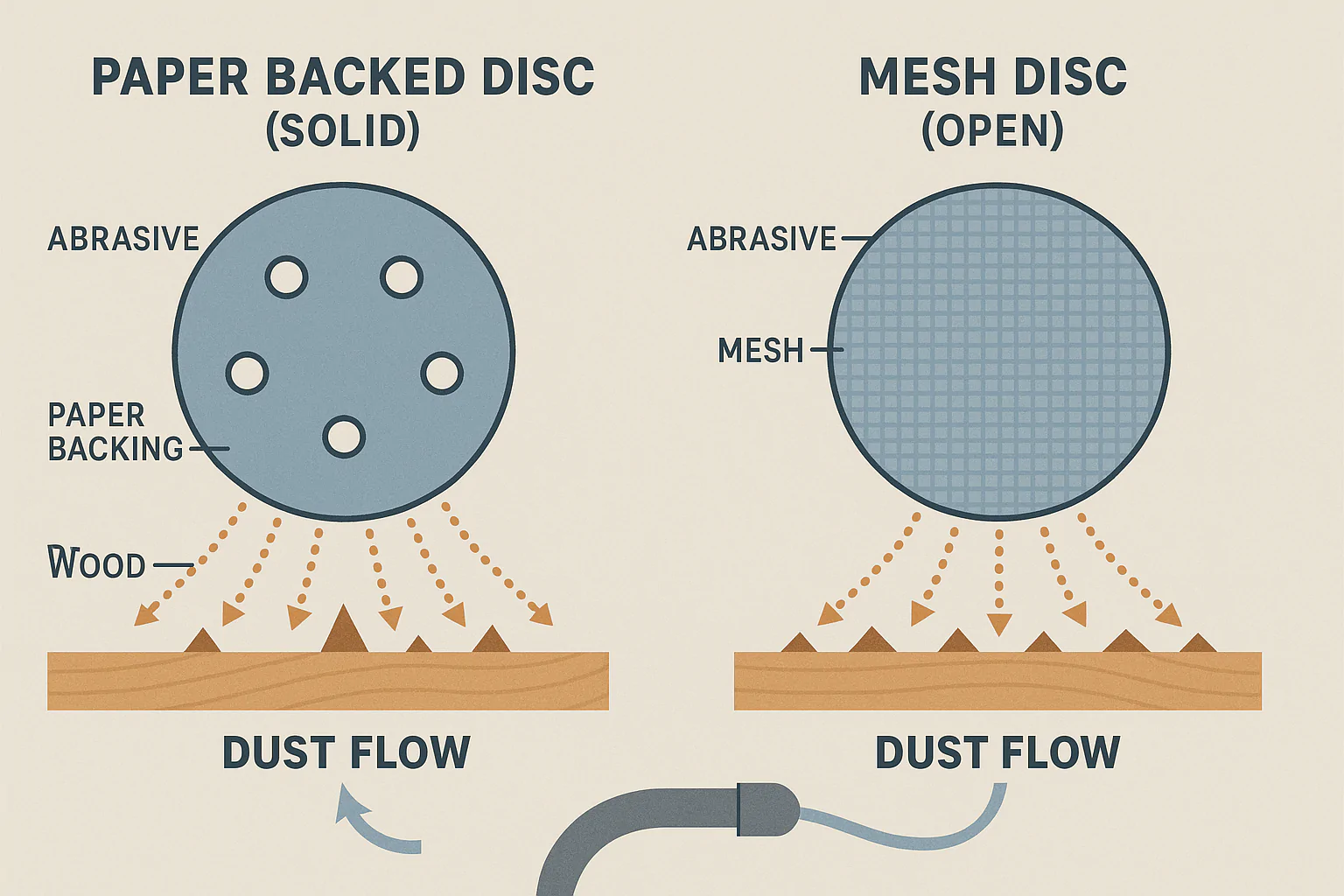

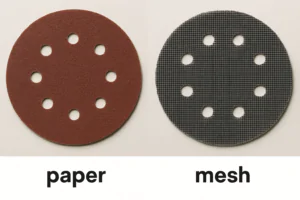

The choice between paper back and mesh sanding discs depends primarily on the material being sanded and whether dust collection is a priority. Paper-backed discs are versatile and widely available in various abrasive types and grits, offering consistent performance and durability for general-purpose sanding on wood, metal, and painted surfaces, suitable for both hand and power sanding applications. Mesh sanding discs excel in dust-generating applications like sanding drywall, fillers, and some paints, allowing dust to pass through their open structure to prevent clogging and extend disc life, making them ideal when used with dust extraction systems for a cleaner environment.

Comparing the structure of paper and mesh sanding discs.

Understanding the strengths of each backing type helps you make the most informed decision for your sanding tasks.

Are mesh sanding discs any good?

Beyond just the comparison with paper, do mesh sanding discs hold up as effective and reliable abrasives on their own merits?

Yes, mesh sanding discs are very good and provide significant benefits in specific applications. They are highly effective at preventing clogging when sanding materials that produce fine, powdery dust, which dramatically extends their usable life compared to paper discs in these conditions. Their open design ensures excellent dust extraction when used with compatible sanders and vacuum systems, leading to a cleaner workspace and improved air quality. Mesh discs provide consistent cutting performance over time, making them a valuable and efficient abrasive choice, especially for tasks where dust is a major challenge.

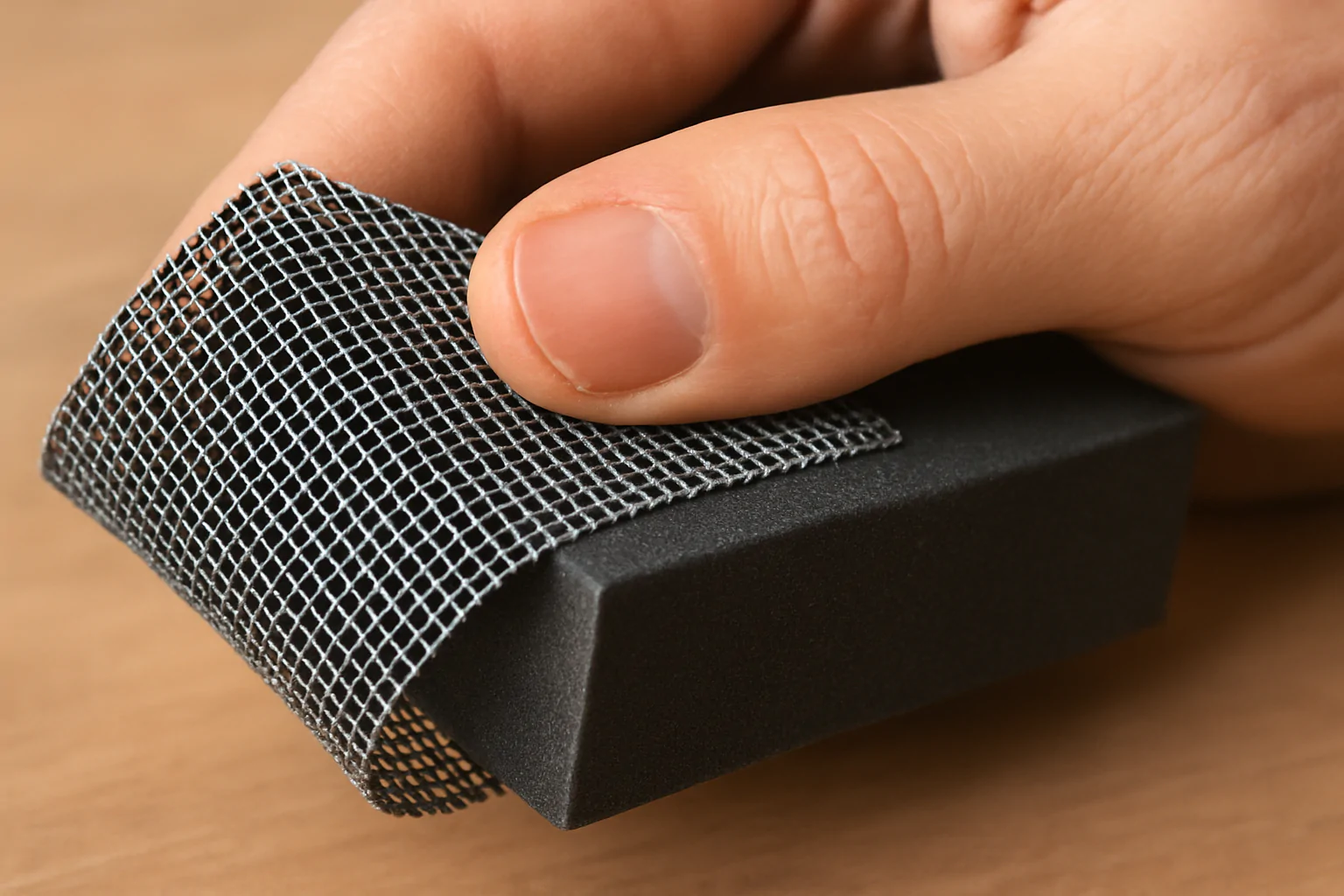

A close-up view of mesh abrasive on a hand block.

When I first started using mesh discs, I was a bit skeptical. They felt different – lighter, less rigid than traditional paper. But after using them on drywall patches and sanding primer, I became a convert for those specific jobs. The most impressive thing is how long they last when sanding materials like joint compound. With paper discs, I would often have to change them every few minutes because the dust would completely fill the space between the abrasive grains, making the disc useless. Mesh discs, because the dust passes right through, keep cutting for much, much longer. This isn’t just a minor convenience; it makes the work faster and reduces the number of discs I go through on a project, which adds up in cost savings. Also, the dust collection is noticeably better. If your sander has good dust collection, using a mesh disc means almost no dust on the surface you’re working on, and very little in the air. This creates a cleaner, safer environment. While they might not feel as aggressive as a brand new, very coarse paper disc for initial heavy stock removal on hard wood, their sustained cutting ability on dusty materials more than makes up for it. For anyone working with drywall, fillers, or certain paints, mesh discs are absolutely worth trying. High-quality mesh abrasives, like those from NOVOGRIT, are manufactured with durable mesh backings and premium grains designed to maximize these benefits.

Which 3 sandpapers are most recommended?

With the vast array of sandpaper types available, identifying the most essential ones can be tricky. If you could only pick three, which would be the most recommended for general use?

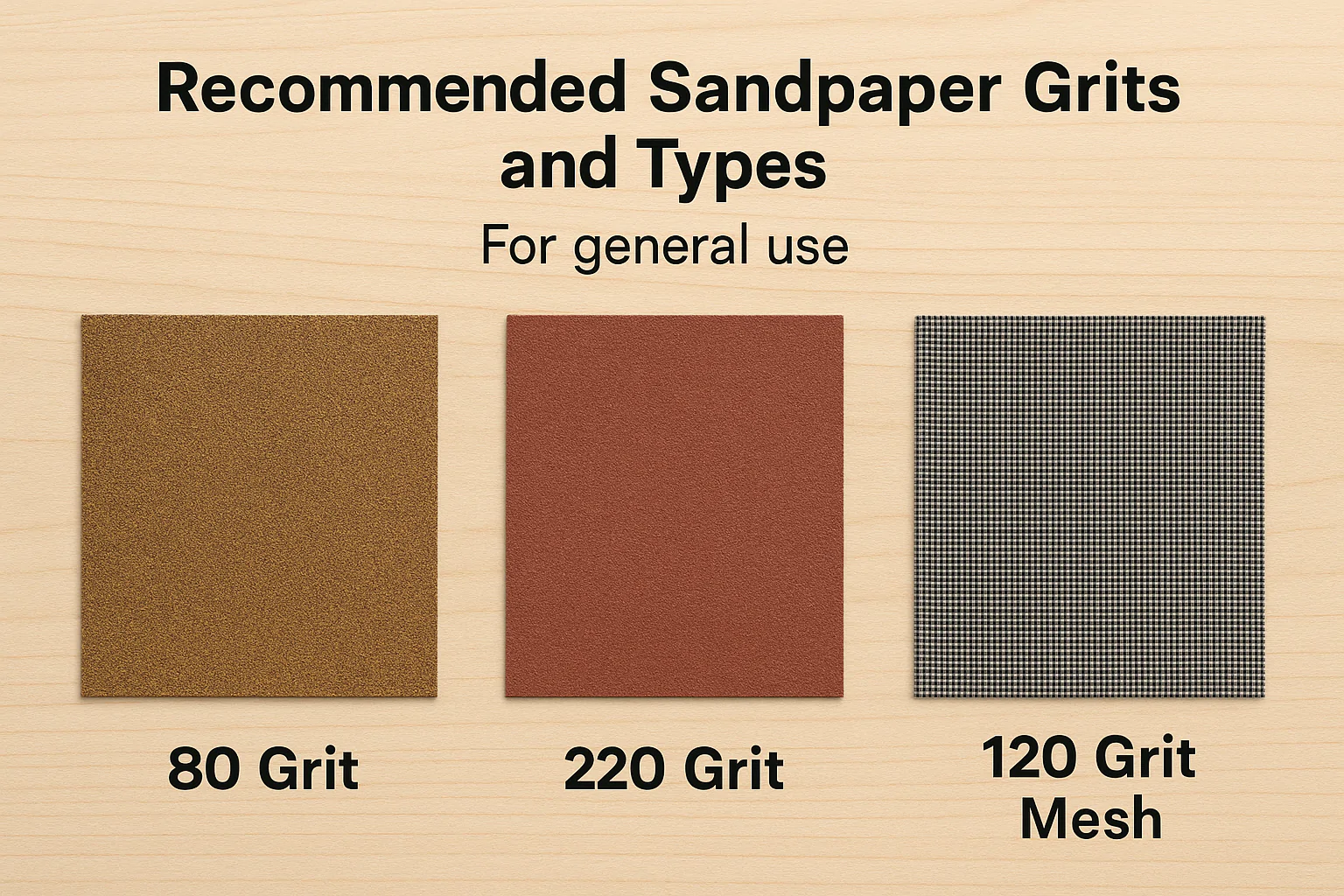

Selecting the "most recommended" three sandpapers depends heavily on the typical projects, but for general woodworking, DIY, and home improvement, a versatile trio would often include: 1. A medium grit (like 80 or 120 grit) Aluminum Oxide sandpaper for general material removal, shaping, and smoothing surfaces. 2. A fine grit (like 220 grit) Aluminum Oxide sandpaper for final smoothing before applying finishes. 3. A medium to fine grit (like 120 or 180 grit) mesh sanding disc or sheet for applications with high dust generation, such as sanding drywall or fillers, offering excellent dust control and longevity.

Three highly recommended abrasive types for general use.

If I had to narrow it down to just three essential abrasives for a general workshop or DIYer, these would be my picks, covering a wide range of tasks:

-

Medium Grit (80-120) Aluminum Oxide Paper: This is your workhorse. Aluminum oxide is durable and works well on wood, metal, and painted surfaces. An 80 or 100 grit is great for moderate material removal and smoothing rough surfaces, while 120 grit is often the first step after initial shaping or planing, preparing the surface for finer grits. It’s versatile and relatively inexpensive.

-

Fine Grit (220) Aluminum Oxide Paper: This is crucial for preparing surfaces for most finishes. Sanding wood to 220 grit closes the pores enough to provide a smooth feel without inhibiting stain absorption (though some prefer to stop at 180 for staining). For paint or clear coats, 220 grit provides an excellent base. It’s also used for light scuffing between finish coats.

-

Medium Grit (120-180) Sanding Mesh: This adds a crucial capability, especially if you ever work on walls, ceilings, or furniture repairs involving fillers. As discussed, its ability to prevent clogging when sanding drywall, joint compound, wood filler, or primer is invaluable. A 120 or 180 grit mesh provides a good balance for smoothing these materials effectively while managing dust. Even if you don’t have a sander with a dust vacuum, the mesh still loads up slower than paper. This adds efficiency and a cleaner work area that traditional paper struggles to provide in these specific, but common, situations.

Having these three types on hand – a versatile medium paper, a fine finishing paper, and a dust-managing mesh – covers the vast majority of sanding needs for typical projects. Of course, for specialized tasks like heavy grinding or automotive work, you might need different abrasive types or grits, but this trio is a solid foundation. NOVOGRIT manufactures high-quality versions of all these essential abrasive types.

Conclusion

Paper-backed discs are versatile for general sanding, while mesh excels in dust control for specific materials like drywall and fillers. Both are good, but mesh offers significant advantages where clogging is an issue. For general use, recommended abrasives include medium and fine grit aluminum oxide paper, plus a medium grit sanding mesh for dusty tasks.

You may also be interested in:

What is the difference between zirconium, ceramic, and aluminum oxide abrasives?

Choosing the right abrasive can be confusing. Using the wrong one wastes time, ruins your workpiece, and costs you money. Let’s make the choice simple for you. The main difference

Best Sandpaper for Aluminum: NOVOGRIT's Guide to Flawless Finishes

What is the Best Type of Sandpaper to Use on Aluminum? Do you find yourself frustrated by sandpaper that gums up instantly when you try to smooth aluminum? It is

Best Sandpaper for Paint Removal: Grits, Types, & Tips | NOVOGRIT

What is the Best Sandpaper for Removing Paint? Are you tired of staring at chipped, peeling paint on your furniture, walls, or even your car? It's a common problem, and

Automotive Wet Sanding: Supplies, Liquids & Best Sandpaper

Automotive Wet Sanding Supplies: What Do You Really Need? Wet sanding is a crucial technique in automotive refinishing, used to achieve a flawlessly smooth surface before painting or polishing. Unlike

Best Sandpaper for Paint Removal & Grit Guide

What Is the Best Sandpaper for Removing Paint? Removing old paint can be a tedious job, but using the right sandpaper makes all the difference. It's not just about grit;

Hardwood Floor Sanding: Screen vs. Sandpaper & Best Practices

Sanding Screen vs. Sandpaper for Hardwood Floors: Which is Best? When you're tackling hardwood floor projects, choosing the right abrasive is crucial for achieving a smooth, professional finish. Both sanding

Sanding Mesh vs Paper: Which is More Economical and Better?

Is Sanding Mesh More Economical Than Sandpaper? Comparing Abrasive Costs When stocking up on abrasives, cost is always a factor. Paper sandpaper has traditionally been the standard, but newer mesh

Sanding Nets & Screens Use Cases: When to Choose Mesh Abrasives

Sanding Nets and Screens: What Are Their Best Use Cases? When you encounter sanding nets or screens, you might wonder where they fit into your sanding projects. Unlike traditional solid-backed

Paper vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper vs. Mesh Sanding Discs: Which Should You Buy? Choosing the right abrasive disc is essential for efficient and effective sanding. Two primary types dominate the market: traditional paper-backed discs