Open vs. Closed Coated Abrasives: Which Should You Use?

When you’re looking at sandpaper or sanding discs, you might see terms like "open coat" or "closed coat." These aren’t just technical jargon; they describe how the abrasive grains are applied and significantly affect how the abrasive performs on different materials.

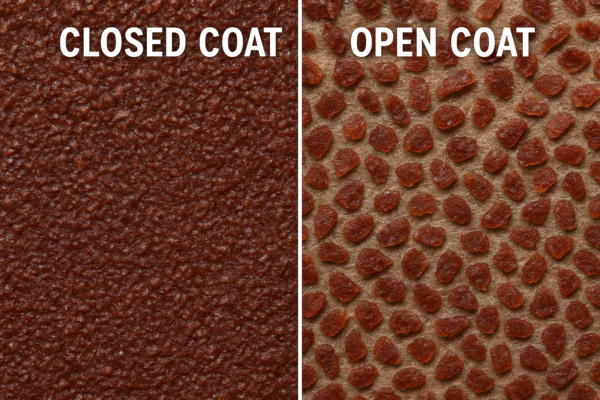

The difference between open and closed coated abrasives lies in the density of the abrasive grain coverage on the backing material. Closed coat abrasives have the abrasive grains packed tightly together, covering the entire surface. Open coat abrasives have spaces between the grains, typically covering only 50-70% of the surface.

Visual difference between open and closed abrasive coatings.

Understanding this difference is key to choosing the right abrasive for your project, especially when dealing with materials that produce a lot of dust or heat.

What is the difference between open coat and closed coat paper?

Specifically focusing on sandpaper or sanding paper, how does the "open coat" versus "closed coat" distinction manifest on this common backing material?

The difference between open coat and closed coat paper refers to the pattern and density of abrasive grains glued onto the paper backing. Open coat paper has grains spaced out with gaps between them, designed to resist clogging, while closed coat paper has grains covering the entire surface densely packed together, offering maximum cutting points.

Close-up view showing grain density on sandpaper.

When manufacturing sandpaper, after the paper backing receives a base adhesive layer, the abrasive grains are applied. For closed coat paper, the grains are applied to cover as much of the surface area as possible. This maximizes the number of cutting edges in contact with the workpiece, leading to faster material removal and potentially a smoother finish, especially with finer grits. However, this dense packing leaves little space for the removed material (dust or swarf) to go. On the other hand, for open coat paper, the grains are intentionally spaced apart, covering only a portion of the surface. The empty spaces between the grains act as channels for dust and debris, preventing them from building up and "loading" or clogging the abrasive surface. Clogging renders the abrasive ineffective as the grains can no longer cut. This is particularly important when sanding soft woods, painted surfaces, drywall compound, or fillers, which produce fine, sticky dust that easily clogs traditional closed-coat abrasives. For example, when sanding wood with NOVOGRIT wood sanding discs, you will often find them in an open coat configuration to minimize clogging and extend the lifespan of the disc. The choice between open and closed coat paper depends heavily on the material being sanded.

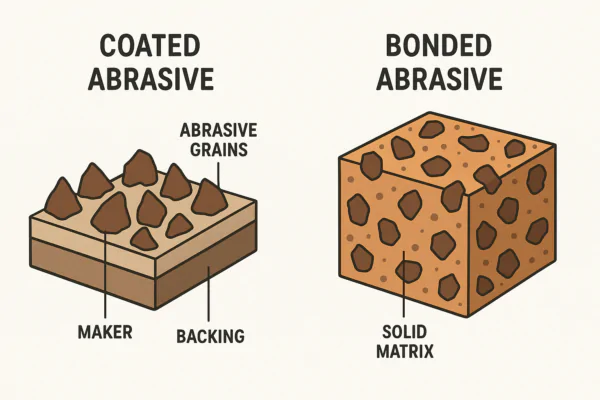

What are the differences between coated and bonded abrasives?

Beyond the open/closed distinction within coated abrasives, how does the broader category of coated abrasives differ from bonded abrasives?

Coated abrasives consist of abrasive grains adhered as a single layer onto a flexible backing material (like paper, cloth, or film). Bonded abrasives, conversely, have abrasive grains mixed throughout a bonding agent (like resin, rubber, or vitrified materials) forming a rigid, solid structure, such as grinding wheels or cutting discs.

Structural differences between coated and bonded abrasives.

The structural difference dictates their primary applications. Coated abrasives are designed for surface finishing, shaping, and relatively light to moderate material removal. Their flexibility allows them to conform to contours and surfaces, making them ideal for sanding, polishing, and deburring across various industries, including furniture and automotive aftermarket sectors served by companies like Hangzhou sharp Technology Co., Ltd. Bonded abrasives, due to their rigid, three-dimensional structure, are used for more aggressive operations like heavy grinding, cutting, and shaping hard materials. Grinding wheels, cut-off wheels, and mounted points are common examples. They are capable of removing much more material quickly and are designed to withstand higher forces and speeds than coated abrasives. While both utilize abrasive grains (such as aluminum oxide, silicon carbide, or even diamond/CBN), the way these grains are presented and supported defines their category and intended use. Coated abrasives wear down as the top layer of grains dulls or pulls away, requiring replacement of the sheet, belt, or disc. Bonded abrasives wear down from the outer layer as the bond releases dull grains and exposes new sharp ones.

When would you choose to use an open coated abrasive in preference to a closed coated one?

Given the properties of each, in which scenarios would an open coated abrasive be the better choice over a closed coated abrasive?

You would choose an open coated abrasive primarily when sanding materials that produce a lot of dust or are prone to clogging, such as wood, paint, varnish, drywall compound, plaster, and certain soft metals or plastics. The open spaces between the grains effectively channel away the swarf, preventing the abrasive surface from loading up and becoming ineffective prematurely.

Open coat resists clogging better on soft materials.

Sanding materials like wood generates fine dust that, when combined with the heat from friction, can easily stick between the densely packed grains of a closed coat abrasive. This "loading" or "clogging" significantly reduces the abrasive’s cutting efficiency, causes it to generate excessive heat (potentially burning the workpiece), and requires frequent replacement or cleaning of the abrasive. Open coat abrasives mitigate this problem by providing pathways for the dust to escape, allowing the abrasive grains to remain in contact with the workpiece for longer. While an open coat abrasive has fewer cutting points in contact at any given moment compared to a closed coat of the same grit, its ability to resist clogging means it can maintain effective cutting performance over a longer period and remove a substantial amount of material without quickly becoming useless. For applications in the furniture industry or automotive aftermarket bodywork where fillers and primers are sanded extensively, using open coat abrasive discs, like those offered by NOVOGRIT, is crucial for efficient and cost-effective work due to the materials involved producing high volumes of fine dust.

What does a closed coat mean?

To clarify, what exactly does the term "closed coat" signify when describing a coated abrasive product?

A "closed coat" on a coated abrasive means that the abrasive grains are applied in a dense pattern, covering essentially the entire surface area of the backing material. There are minimal gaps between the individual abrasive grains.

Microscopic view of a closed coat abrasive surface.

This dense packing maximizes the number of abrasive grains in contact with the workpiece at any given time. With more cutting edges engaged, a closed coat abrasive can remove material very efficiently and is often preferred for applications where a smooth finish is desired and the material being sanded does not produce excessive, sticky dust. They are commonly used for sanding hard metals, plastics, or for final finishing stages on harder woods or clear coats where the swarf is minimal and less likely to clog the surface. While they offer aggressive cutting power and the potential for a finer finish (especially with finer grits), their vulnerability to clogging on softer or dust-prone materials is their primary limitation compared to open coat varieties. Therefore, if you are working on materials like steel or certain hard composites where dust loading is not a major issue, a closed coat abrasive from manufacturers like NOVOGRIT would likely offer superior cutting speed and a potentially smoother result.

Conclusion

Choosing between open and closed coated abrasives depends entirely on the material you are sanding. Open coat resists clogging on soft materials, while closed coat offers maximum cutting points for harder materials where dust is less of an issue. Understanding this difference ensures you select the most effective abrasive for your specific task.

You may also be interested in:

What is the difference between zirconium, ceramic, and aluminum oxide abrasives?

Choosing the right abrasive can be confusing. Using the wrong one wastes time, ruins your workpiece, and costs you money. Let’s make the choice simple for you. The main difference

Best Sandpaper for Aluminum: NOVOGRIT's Guide to Flawless Finishes

What is the Best Type of Sandpaper to Use on Aluminum? Do you find yourself frustrated by sandpaper that gums up instantly when you try to smooth aluminum? It is

Best Sandpaper for Paint Removal: Grits, Types, & Tips | NOVOGRIT

What is the Best Sandpaper for Removing Paint? Are you tired of staring at chipped, peeling paint on your furniture, walls, or even your car? It's a common problem, and

Automotive Wet Sanding: Supplies, Liquids & Best Sandpaper

Automotive Wet Sanding Supplies: What Do You Really Need? Wet sanding is a crucial technique in automotive refinishing, used to achieve a flawlessly smooth surface before painting or polishing. Unlike

Best Sandpaper for Paint Removal & Grit Guide

What Is the Best Sandpaper for Removing Paint? Removing old paint can be a tedious job, but using the right sandpaper makes all the difference. It's not just about grit;

Hardwood Floor Sanding: Screen vs. Sandpaper & Best Practices

Sanding Screen vs. Sandpaper for Hardwood Floors: Which is Best? When you're tackling hardwood floor projects, choosing the right abrasive is crucial for achieving a smooth, professional finish. Both sanding

Paper Backing vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper Back vs. Mesh Sanding Discs: Which One Should You Pick? Choosing the right sanding disc backing can significantly impact your project's efficiency and finish quality. Paper-backed discs are a

Sanding Mesh vs Paper: Which is More Economical and Better?

Is Sanding Mesh More Economical Than Sandpaper? Comparing Abrasive Costs When stocking up on abrasives, cost is always a factor. Paper sandpaper has traditionally been the standard, but newer mesh

Sanding Nets & Screens Use Cases: When to Choose Mesh Abrasives

Sanding Nets and Screens: What Are Their Best Use Cases? When you encounter sanding nets or screens, you might wonder where they fit into your sanding projects. Unlike traditional solid-backed