Is Sandpaper Essentially Sand Glued to Paper?

You’ve probably used sandpaper before. It feels rough and helps smooth things out. But is it just sand stuck to paper?

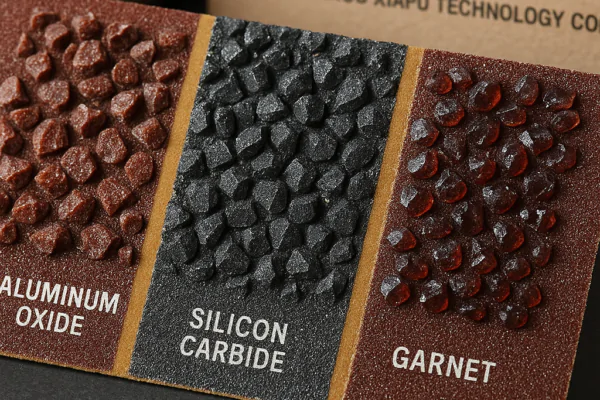

No, sandpaper is not just sand glued to paper. While it has abrasive particles attached to a backing, the "sand" is actually made of different materials like aluminum oxide, silicon carbide, or even garnet. These materials are much harder and sharper than natural sand.

It’s not just sand on paper, it’s carefully chosen materials.

It’s easy to think of sandpaper as just sand. After all, it has "sand" in the name. But the reality is more complex and involves some clever manufacturing processes. Let’s explore what makes sandpaper work.

How Do You Get Sand to Stick to Paper?

Getting those hard abrasive particles to stay put on the backing is key. How do they make them stick so well?

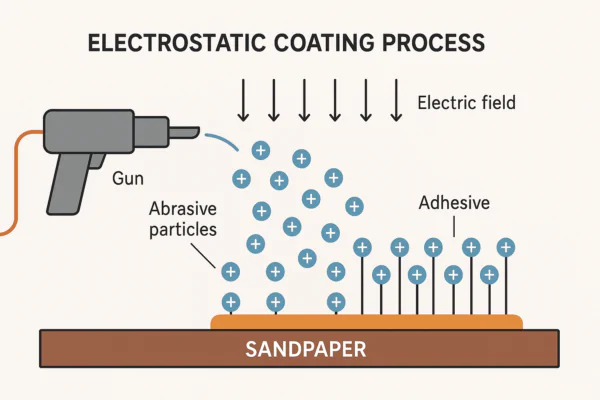

The process of getting abrasive particles to stick to the backing of sandpaper involves using strong adhesives and often an electrostatic application. This method ensures the grains are evenly spaced and oriented for effective sanding.

This image shows how the abrasive particles are applied.

Getting the abrasives to stick isn’t just about putting glue on paper. It’s a precise process that uses special techniques. Here’s a closer look at how it works:

The Role of Adhesives

What kind of glue is used?

Sandpaper uses durable resins and glues. These are much stronger than everyday craft glue. They can hold up to the heat and friction created during sanding.

The Electrostatic Coating Process

How does electricity help?

This is a common method for applying the abrasive grains.

- The backing gets a coat of adhesive. This is the base layer the grains will stick to.

- The abrasive grains are given an electric charge. This makes them attracted to the adhesive layer on the backing.

- The charged grains are dropped or blown towards the adhesive. Because of the charge, they stand up straight on the adhesive. This creates a consistent cutting surface.

This electrostatic process is important. It makes sure the grains are spread out evenly. It also helps them stand up. This means the sandpaper cuts more effectively.

Different Backing Materials

Is it always paper?

No, sandpaper backings can be more than just paper.

- Paper: Common for general use. Different weights are available.

- Cloth: More flexible and durable, good for power sanding.

- Film: Very uniform in thickness, used for fine finishing.

The combination of the right adhesive, the application process, and the backing material creates sandpaper that performs well for different jobs.

Is Sandpaper Environmentally Friendly?

We use a lot of sandpaper. But what happens to it when we’re done? Is it good or bad for the environment?

Most traditional sandpaper is not easily recyclable due to the mix of materials used, such as different types of abrasive grains, adhesives, and backings. This makes disposal a challenge for the environment.

Used sandpaper often ends up in landfills.

Considering the impact of materials is important. Sandpaper uses various materials that are difficult to separate. This makes recycling a complex issue. Let’s think about the environmental impact of sandpaper.

The Materials Involved

What are the main parts?

Sandpaper is made of several layers:

- Abrasive grains: These can be natural or synthetic minerals.

- Adhesives: Strong glues that hold the grains to the backing.

- Backing: Paper, cloth, or film.

Mixing these different materials makes recycling difficult. Standard recycling processes can’t easily separate them.

End-of-Life Disposal

Where does it go?

Most used sandpaper goes to landfills. The materials don’t break down easily. This can contribute to waste accumulation.

Looking for More Sustainable Options

Are there better choices?

Some companies are starting to think about this problem.

- Recycled Backings: Some sandpaper might use recycled paper or cloth for the backing.

- Alternative Abrasives: Research is being done on more sustainable abrasive materials.

- Extended Lifespan: Making sandpaper last longer reduces the amount thrown away. Buying higher quality sandpaper that lasts longer can be a more sustainable choice in the long run.

While fully recyclable sandpaper is not widely available yet, awareness of the issue is growing. Choosing the right grit for the job and using sandpaper efficiently can also help reduce waste.

Conclusion

Sandpaper is more than just sand on paper. It uses special abrasive materials, strong adhesives, and different backings. While traditional sandpaper isn’t easily recyclable, efforts are being made to find more sustainable options for the future.

You may also be interested in:

What is the difference between zirconium, ceramic, and aluminum oxide abrasives?

Choosing the right abrasive can be confusing. Using the wrong one wastes time, ruins your workpiece, and costs you money. Let’s make the choice simple for you. The main difference

Best Sandpaper for Aluminum: NOVOGRIT's Guide to Flawless Finishes

What is the Best Type of Sandpaper to Use on Aluminum? Do you find yourself frustrated by sandpaper that gums up instantly when you try to smooth aluminum? It is

Best Sandpaper for Paint Removal: Grits, Types, & Tips | NOVOGRIT

What is the Best Sandpaper for Removing Paint? Are you tired of staring at chipped, peeling paint on your furniture, walls, or even your car? It's a common problem, and

Automotive Wet Sanding: Supplies, Liquids & Best Sandpaper

Automotive Wet Sanding Supplies: What Do You Really Need? Wet sanding is a crucial technique in automotive refinishing, used to achieve a flawlessly smooth surface before painting or polishing. Unlike

Best Sandpaper for Paint Removal & Grit Guide

What Is the Best Sandpaper for Removing Paint? Removing old paint can be a tedious job, but using the right sandpaper makes all the difference. It's not just about grit;

Hardwood Floor Sanding: Screen vs. Sandpaper & Best Practices

Sanding Screen vs. Sandpaper for Hardwood Floors: Which is Best? When you're tackling hardwood floor projects, choosing the right abrasive is crucial for achieving a smooth, professional finish. Both sanding

Paper Backing vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper Back vs. Mesh Sanding Discs: Which One Should You Pick? Choosing the right sanding disc backing can significantly impact your project's efficiency and finish quality. Paper-backed discs are a

Sanding Mesh vs Paper: Which is More Economical and Better?

Is Sanding Mesh More Economical Than Sandpaper? Comparing Abrasive Costs When stocking up on abrasives, cost is always a factor. Paper sandpaper has traditionally been the standard, but newer mesh

Sanding Nets & Screens Use Cases: When to Choose Mesh Abrasives

Sanding Nets and Screens: What Are Their Best Use Cases? When you encounter sanding nets or screens, you might wonder where they fit into your sanding projects. Unlike traditional solid-backed