Is Sanding Resin Dangerous? Understanding the Risks and Staying Safe

Working with resin has become incredibly popular for crafts, art, and repairs. While the liquid resin itself has specific handling requirements, sanding cured resin also presents potential health hazards that many people might overlook. Knowing these risks is crucial for safe practice.

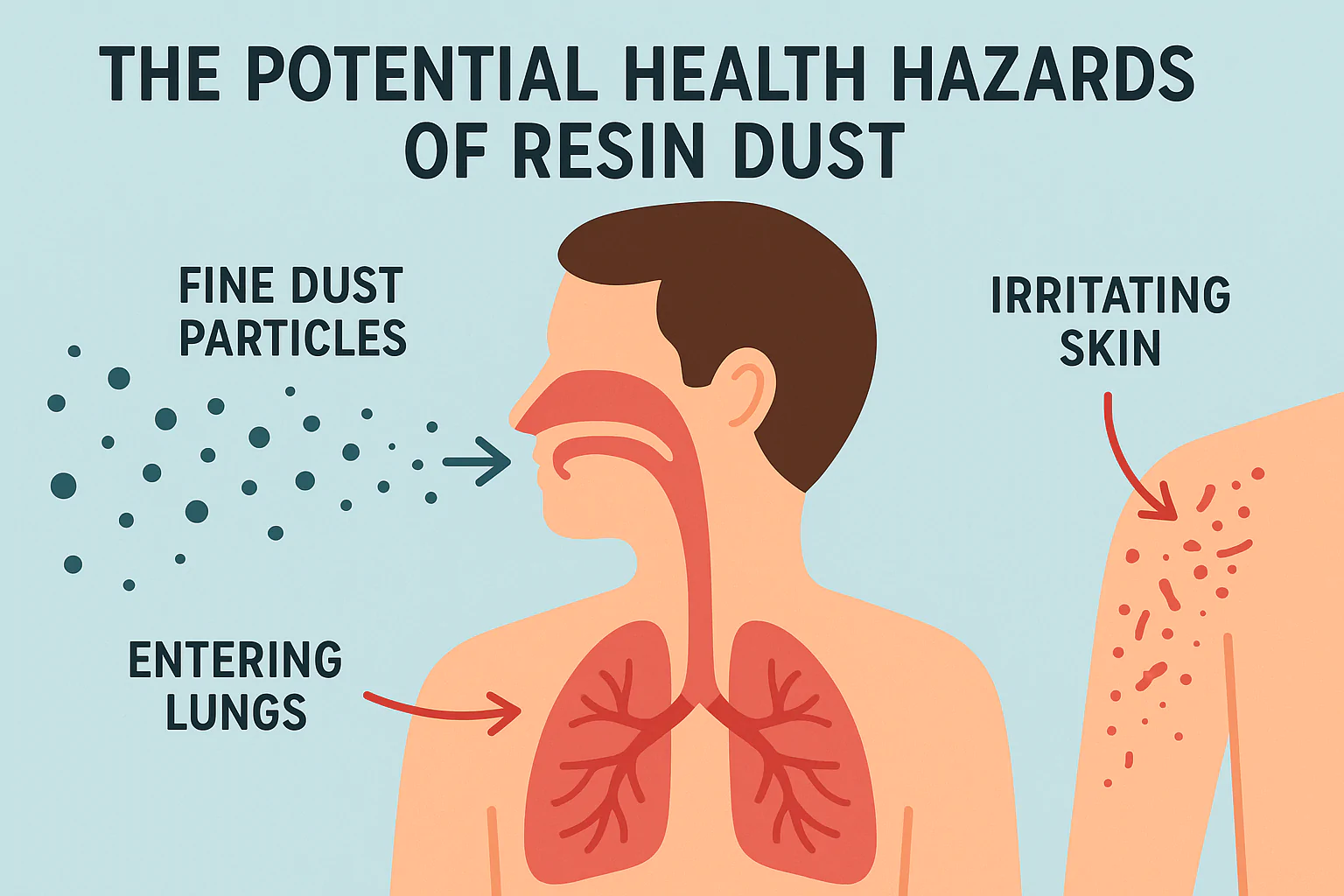

Sanding cured resin can be dangerous primarily due to the fine dust particles it generates. This dust can contain harmful chemicals from the resin and hardener, irritating the skin, eyes, and respiratory system if inhaled. The friction from sanding also creates heat, which can potentially release fumes. Therefore, proper ventilation, personal protective equipment (PPE), and wet sanding techniques are essential to mitigate these risks.

Proper safety measures for sanding resin.

Ignoring these precautions can lead to both short-term irritation and long-term health issues.

Is it dangerous to sand resin?

So, putting it plainly, is sanding cured resin something you need to worry about from a safety perspective?

Yes, it is definitely dangerous to sand cured resin if proper safety precautions are not taken. The danger comes from inhaling the fine resin dust, which can contain unreacted chemicals, causing respiratory irritation, sensitization, and potentially long-term lung damage. Skin contact with the dust can also cause irritation or allergic reactions. Heat generated during dry sanding can also release harmful vapors. Therefore, adequate ventilation, respiratory protection, eye protection, and skin protection are vital.

The potential health hazards of resin dust.

Even when resin is fully cured according to the manufacturer’s instructions, tiny amounts of unreacted chemicals from the resin and hardener components can remain trapped within the solid matrix. When you sand the resin, you break this matrix apart, releasing these chemicals along with the resin particles into the air as a very fine dust. This dust is small enough to be inhaled deep into the lungs. For some people, exposure can cause immediate irritation to the throat, nose, and lungs, leading to coughing or difficulty breathing. More seriously, repeated exposure can lead to sensitization, where the body develops an allergic reaction to the chemicals, making future exposure (even to very small amounts) trigger severe reactions, including asthma-like symptoms or dermatitis. Dry sanding also generates friction and heat. This heat can be enough to cause some residual chemicals or additives in the resin to vaporize, releasing fumes that can also be irritating or harmful to inhale. Wet sanding significantly reduces both dust generation and heat buildup, making it a much safer method for working with cured resin. Always consult the safety data sheet (SDS) for the specific resin product you are using to understand its particular hazards and recommended safety measures, even after curing.

Should I wear a mask when sanding resin?

Given the risks of inhaling resin dust, is wearing a mask sufficient protection, and what type of mask is recommended?

Yes, you absolutely should wear a mask, specifically a respirator, when sanding resin to protect your lungs from inhaling fine resin dust and potential fumes. A simple paper dust mask is not sufficient as it won’t filter out the very fine particles or chemical vapors. You need at least an N95 respirator rated for fine particulates, or ideally, a respirator with organic vapor cartridges combined with a particulate filter if concerned about heat-generated fumes.

Wearing an N95 respirator for dust protection.

Protecting your respiratory system is one of the most critical safety steps when sanding resin. The dust generated is fine and easily inhaled. Standard disposable paper dust masks offer minimal protection against these types of fine particles. You need a mask that is certified to filter out at least 95% of airborne particles. An N95 disposable respirator (or higher, like N99 or N100) is the minimum recommended protection for resin dust. Ensure the respirator fits snugly against your face; a poor seal allows dust to bypass the filter. For better protection, especially if you are sanding frequently or using methods that generate significant heat (like power sanding), or if you are concerned about potential fumes from partially cured or certain types of resin, a half-facepiece respirator with interchangeable cartridges is recommended. Use cartridges rated for organic vapors combined with particulate filters (often labeled as P100). This type of respirator offers a better seal and filters out both the fine dust and many types of chemical vapors. Remember that respirators need to be replaced regularly; particulate filters become clogged, and organic vapor cartridges become saturated. Always follow the manufacturer’s guidelines for your specific mask or respirator. While NOVOGRIT provides high-quality abrasives perfect for sanding resin (especially wet/dry options), they also emphasize the importance of proper PPE to use those abrasives safely.

How toxic is resin dust?

We’ve established that resin dust is dangerous, but what specifically makes it toxic, and what are the potential long-term health effects?

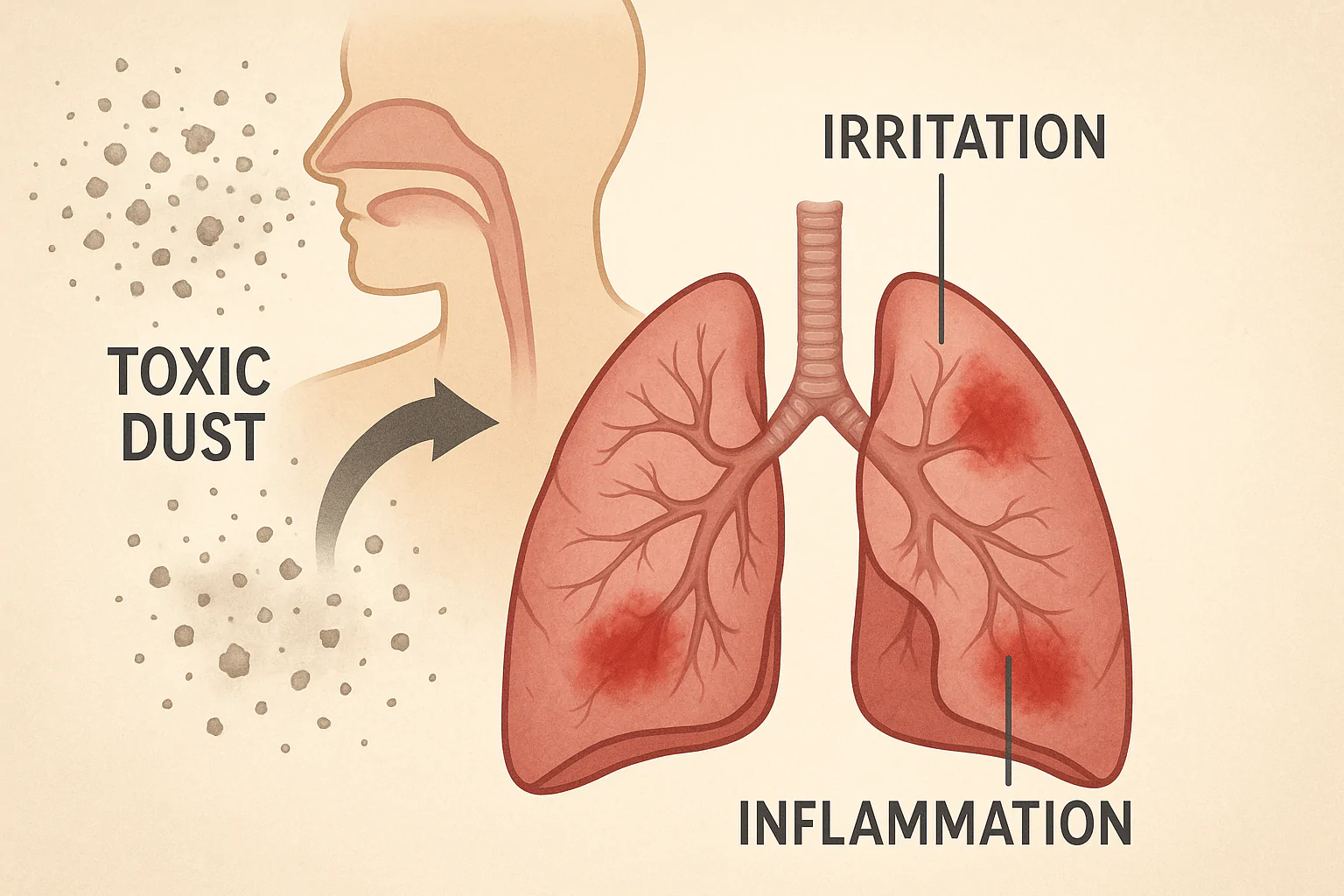

Resin dust toxicity comes from inhaling fine particles that can contain residual reactive chemicals (like monomers or amines) from the uncured or partially cured resin/hardener system. These chemicals, even in small amounts, can cause irritation, sensitization, and allergic reactions. Chronic or repeated exposure to resin dust can potentially lead to serious long-term health problems, including occupational asthma, other respiratory diseases, and persistent skin allergies (contact dermatitis).

How toxic dust affects the respiratory system.

The danger isn’t just from the inert resin material itself, but from the potentially still-active chemical components. Even in what seems like a fully cured piece, tiny amounts of the original liquid chemicals might not have fully reacted. When you sand, these unreacted chemicals are released into the air on the surface of the tiny dust particles. For many epoxy, polyester, or urethane resins, these can include irritants, sensitizers, and allergens. Inhaling these can immediately irritate the delicate tissues of the respiratory tract. The more significant long-term risk is sensitization. This is an immune response where your body becomes hypersensitive to a substance. After sensitization occurs (which can happen after a single large exposure or repeated small exposures), even minimal contact in the future can trigger a severe allergic reaction. In the lungs, this can manifest as occupational asthma, a chronic and potentially debilitating respiratory condition. On the skin, it can cause severe, persistent contact dermatitis. The toxicity also depends on the specific type of resin system used; some are more hazardous than others. Always check the safety data sheet (SDS) provided by the resin manufacturer for detailed information on the specific health risks associated with the cured dust. Proper safety measures are the only way to prevent these serious health outcomes.

What happens when you sand resin?

Putting it all together, when you sand a piece of cured resin, what physical processes occur and what are the safety implications of each?

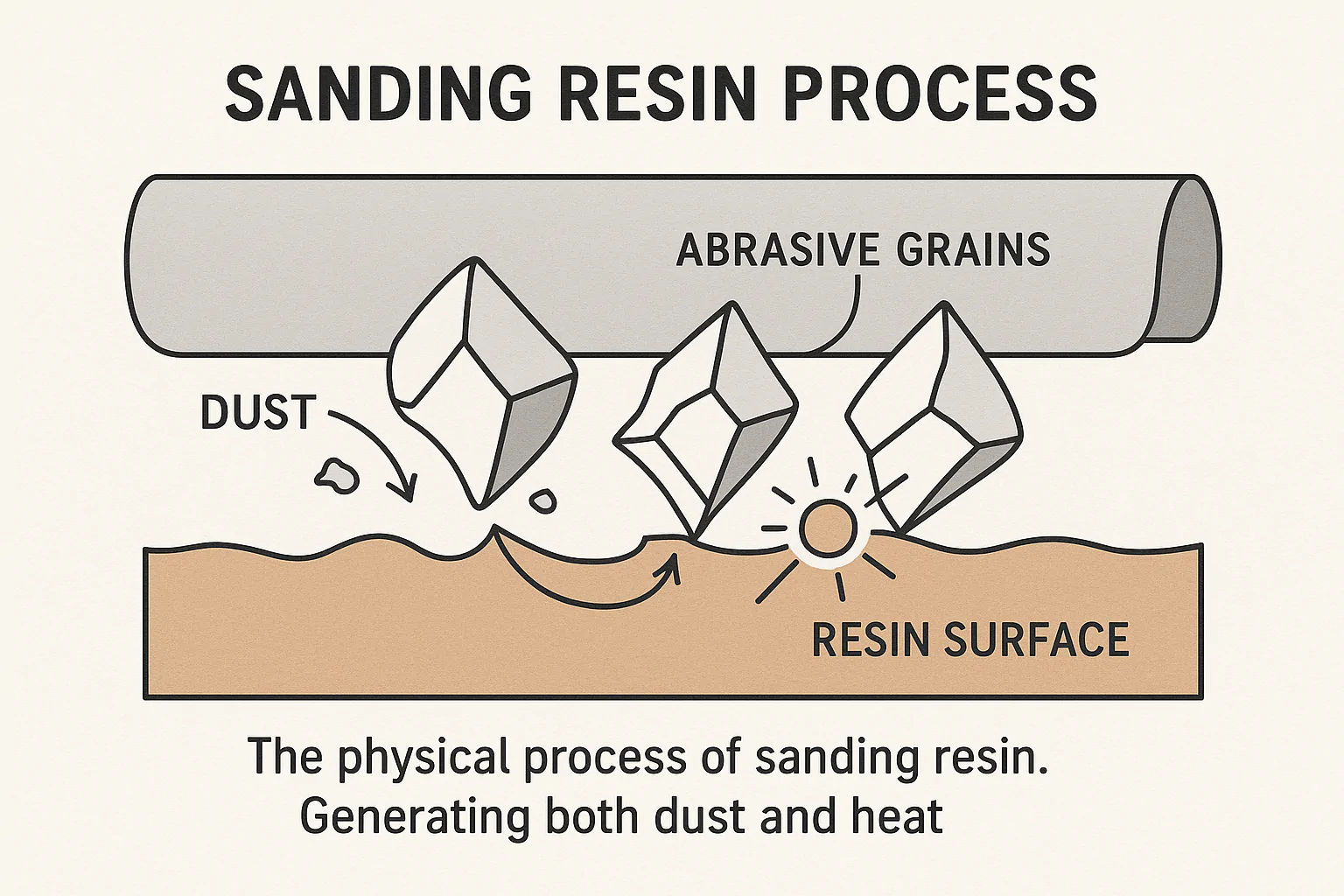

When you sand resin, abrasive particles mechanically remove tiny fragments of the cured material, creating a significant amount of very fine dust. This friction also generates heat, which can potentially cause the release of volatile organic compounds (VOCs) or other chemical fumes from the resin. The fine dust, containing resin particles and possibly unreacted chemicals, becomes airborne and can be inhaled or settle on the skin and surfaces. Wet sanding mitigates these issues by trapping dust in water and keeping temperatures lower.

The physical process of sanding resin.

Imagine the abrasive grains on your sandpaper or sanding disc (like those from NOVOGRIT, designed for effective material removal) acting like tiny chisels. As you move the sandpaper across the resin surface, these chisels scrape away minuscule pieces of the cured resin. The harder the resin and the coarser the grit, the more material is removed with each pass. This removed material is the dust. Because cured resin is quite brittle, these fragments can break down into extremely fine particles, often small enough to remain suspended in the air for a long time or be easily inhaled. The act of friction between the abrasive and the resin surface generates heat. With dry sanding, this heat can build up, especially with power tools. This heat can cause any residual, more volatile chemicals within the resin to turn into gas (fumes) and become airborne. Both the dust and the fumes are potential health hazards. The dust can irritate the respiratory system and skin, and the fumes can also be irritating or toxic to inhale. The dust settling on skin can also cause irritation or contribute to sensitization. This is why working in a well-ventilated area is crucial to disperse airborne contaminants. Wet sanding dramatically changes this process. The water acts as a lubricant, reducing friction and heat. More importantly, the water captures the dust particles as they are created, forming a slurry instead of allowing them to become airborne. This makes wet sanding significantly safer for your lungs and reduces skin contact with dry dust.

Conclusion

Sanding cured resin is dangerous due to the inhalation of fine, potentially chemical-laden dust and fumes generated by friction and heat. Always use proper ventilation, wear appropriate respiratory protection (at least N95, ideally with organic vapor cartridges), eye protection, gloves, and consider wet sanding techniques to minimize risk and ensure safety.

You may also be interested in:

What is the difference between zirconium, ceramic, and aluminum oxide abrasives?

Choosing the right abrasive can be confusing. Using the wrong one wastes time, ruins your workpiece, and costs you money. Let’s make the choice simple for you. The main difference

Best Sandpaper for Aluminum: NOVOGRIT's Guide to Flawless Finishes

What is the Best Type of Sandpaper to Use on Aluminum? Do you find yourself frustrated by sandpaper that gums up instantly when you try to smooth aluminum? It is

Best Sandpaper for Paint Removal: Grits, Types, & Tips | NOVOGRIT

What is the Best Sandpaper for Removing Paint? Are you tired of staring at chipped, peeling paint on your furniture, walls, or even your car? It's a common problem, and

Automotive Wet Sanding: Supplies, Liquids & Best Sandpaper

Automotive Wet Sanding Supplies: What Do You Really Need? Wet sanding is a crucial technique in automotive refinishing, used to achieve a flawlessly smooth surface before painting or polishing. Unlike

Best Sandpaper for Paint Removal & Grit Guide

What Is the Best Sandpaper for Removing Paint? Removing old paint can be a tedious job, but using the right sandpaper makes all the difference. It's not just about grit;

Hardwood Floor Sanding: Screen vs. Sandpaper & Best Practices

Sanding Screen vs. Sandpaper for Hardwood Floors: Which is Best? When you're tackling hardwood floor projects, choosing the right abrasive is crucial for achieving a smooth, professional finish. Both sanding

Paper Backing vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper Back vs. Mesh Sanding Discs: Which One Should You Pick? Choosing the right sanding disc backing can significantly impact your project's efficiency and finish quality. Paper-backed discs are a

Sanding Mesh vs Paper: Which is More Economical and Better?

Is Sanding Mesh More Economical Than Sandpaper? Comparing Abrasive Costs When stocking up on abrasives, cost is always a factor. Paper sandpaper has traditionally been the standard, but newer mesh

Sanding Nets & Screens Use Cases: When to Choose Mesh Abrasives

Sanding Nets and Screens: What Are Their Best Use Cases? When you encounter sanding nets or screens, you might wonder where they fit into your sanding projects. Unlike traditional solid-backed