How to Sand a Ceiling: Getting a Smooth Surface Overhead

Sanding a ceiling is one of those jobs nobody looks forward to. It’s messy, requires working overhead, and can quickly leave your arms aching. But whether you’re prepping for paint or smoothing a repair, knowing how to sand a ceiling effectively makes the task less daunting.

Sanding a ceiling requires proper preparation, the right tools, and a systematic approach to ensure an even finish and manage dust. The process typically involves using a long-reach sander or manual pole sander with appropriate grit sandpaper to smooth imperfections before painting or texturing.

Using a specialized sander for ceilings with dust control.

Doing it correctly minimizes effort and maximizes the quality of the finished surface, which is crucial since flaws are easily visible on a ceiling.

What’s the Easiest Way to Sand a Ceiling?

Sanding overhead is physically demanding. Is there a method or tool that makes sanding a ceiling significantly easier?

The easiest way to sand a ceiling is generally by using a long-reach drywall sander, often called a "giraffe sander," connected to a dust extraction system. This specialized tool allows you to sand from the floor, reducing strain and effectively capturing dust, although a pole sander is a manual alternative for smaller jobs.

Comparing different methods for sanding ceilings.

A long-reach drywall sander is specifically designed for sanding high walls and ceilings. It has a long pole handle and a swiveling head that holds a large sanding disc, typically 9 inches in diameter. The weight of the motor is often at the base near the handle, making the head lighter to maneuver overhead. Most importantly, these sanders have integrated dust collection ports that connect directly to a powerful vacuum or dust extractor. This captures a large percentage of the dust as you sand, making the job much cleaner and healthier. While a long-reach sander is an investment, it saves a huge amount of time and effort compared to standing on a ladder with a hand sander. For smaller touch-ups or areas, a manual pole sander with a handle and a head that holds standard sandpaper sheets can work, but it still requires physical effort and doesn’t offer built-in dust collection. Using efficient, clog-resistant abrasive discs, like those sometimes available for larger sanding applications from manufacturers like NOVOGRIT, can also make the job go faster and require fewer disc changes.

Should You Sand a Ceiling Before Painting?

You might think you can just paint over an old ceiling, but is sanding really necessary before applying a new coat?

Yes, you should almost always sand a ceiling before painting, especially if it has patches, repairs, old paint drips, or uneven textures. Sanding helps to smooth out imperfections, feather in repairs, and provides a better surface for the new paint to adhere to, leading to a more professional and uniform finish.

The difference sanding makes on a ceiling surface.

Even seemingly flat ceilings can have minor imperfections that become very noticeable once a new coat of paint is applied, particularly if the new paint has a different sheen or color. Previous paint jobs might have left drips or roller marks. Drywall repairs, like filling holes or taping seams, always require sanding to blend the joint compound smoothly into the surrounding surface. If you’re dealing with a textured ceiling and want a smooth finish, sanding is a major part of the process (though this is a much bigger, dustier job). Even on a previously painted smooth ceiling, a light sanding (often called "scuff-sanding") helps to de-gloss the old paint surface, providing "tooth" for the new paint to grip onto. This improves adhesion and durability of the paint finish. Failing to sand can result in a patchy, uneven appearance where imperfections are highlighted rather than hidden by the paint. So, while it’s extra work, sanding is a crucial step for achieving a high-quality ceiling paint finish.

What Kind of Sandpaper Do You Use on Ceilings?

Choosing the right sandpaper grit is important for any sanding job. What type and grit of sandpaper are best for working overhead on a ceiling?

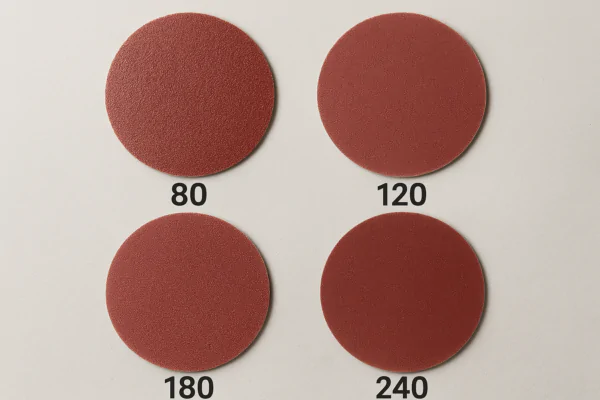

For sanding ceilings, especially drywall compound, you typically use medium to fine grit sandpaper, commonly in the range of 100 to 150 grit. The type of abrasive grain is often aluminum oxide or silicon carbide, applied to a paper or mesh backing. The specific grit depends on the stage of sanding and the desired smoothness.

Examples of sandpaper grits used for ceiling sanding.

When sanding joint compound or patches on a ceiling, the goal is to smooth the surface and blend the repair seamlessly. Starting with a grit that is too coarse (like 60 or 80) can easily create divots or uneven spots, especially in softer joint compound. A medium grit like 100 or 120 is generally a good starting point for smoothing taped seams and patches. If the surface is already relatively smooth and you’re just doing a light scuff-sanding before painting, a finer grit like 150 or even 180 might be sufficient. The abrasive material itself can be aluminum oxide, which is durable and effective for general sanding, or silicon carbide, which is sharper and good for finishing. However, for drywall, aluminum oxide is very common.

The backing material is also important. For large random orbital or long-reach sanders, round sanding discs are used, often with holes for dust extraction. The durability and clog-resistance of the abrasive are key when dealing with soft drywall dust. Some people prefer mesh abrasives, which offer excellent dust collection across the entire surface, reducing clogging. High-quality abrasives, such as those sometimes manufactured with advanced backings by companies like Hangzhou sharp Technology Co., Ltd. under the NOVOGRIT brand, are designed to resist clogging and provide consistent cutting, which is a significant advantage when sanding overhead where frequent disc changes are inconvenient.

What is the Best Sander for Sanding Ceilings?

Given the challenges of sanding a ceiling, which type of electric sander is truly the most effective tool for the job?

The best sander for sanding ceilings, especially large areas, is typically a long-reach random orbital drywall sander with vacuum attachment. Its extended handle allows sanding from the floor, the random orbit motion minimizes swirl marks, and integrated dust collection is crucial for managing the significant amount of dust generated when sanding ceilings.

Operating a long-reach sander on a ceiling.

While you can use a regular random orbital sander while standing on a ladder, this is physically demanding, requires constant repositioning of the ladder, and sends a huge amount of dust into the air and onto everything below. A dedicated long-reach drywall sander solves these problems. The random orbital action of the head helps to create a smooth, swirl-free finish, which is important as ceiling lights can highlight imperfections. The most valuable feature is the integrated dust collection. Sanding drywall compound creates a very fine, pervasive dust. Connecting the sander to a powerful vacuum or dust extractor significantly reduces airborne dust, making the job much cleaner, safer (better for your lungs), and faster as you don’t have to stop as often for cleanup. Some long-reach sanders are heavier than others, so consider the weight and ergonomics if you have a large area to sand. While these sanders are an investment, for anyone doing significant ceiling work, they are well worth the cost in terms of saved time, reduced physical strain, and vastly improved dust control. Using high-quality abrasive discs specifically designed for these sanders, like those with durable backings and effective dust hole patterns from reputable manufacturers, will further enhance performance.

Conclusion

Sanding a ceiling is a tough job, but using the right methods and tools, particularly a long-reach sander with dust collection and appropriate grit abrasives, makes it much more manageable. Sanding is a necessary step before painting to ensure a smooth, professional finish on this highly visible surface. Choosing quality abrasives also contributes to a better outcome.

You may also be interested in:

What is the difference between zirconium, ceramic, and aluminum oxide abrasives?

Choosing the right abrasive can be confusing. Using the wrong one wastes time, ruins your workpiece, and costs you money. Let’s make the choice simple for you. The main difference

Best Sandpaper for Aluminum: NOVOGRIT's Guide to Flawless Finishes

What is the Best Type of Sandpaper to Use on Aluminum? Do you find yourself frustrated by sandpaper that gums up instantly when you try to smooth aluminum? It is

Best Sandpaper for Paint Removal: Grits, Types, & Tips | NOVOGRIT

What is the Best Sandpaper for Removing Paint? Are you tired of staring at chipped, peeling paint on your furniture, walls, or even your car? It's a common problem, and

Automotive Wet Sanding: Supplies, Liquids & Best Sandpaper

Automotive Wet Sanding Supplies: What Do You Really Need? Wet sanding is a crucial technique in automotive refinishing, used to achieve a flawlessly smooth surface before painting or polishing. Unlike

Best Sandpaper for Paint Removal & Grit Guide

What Is the Best Sandpaper for Removing Paint? Removing old paint can be a tedious job, but using the right sandpaper makes all the difference. It's not just about grit;

Hardwood Floor Sanding: Screen vs. Sandpaper & Best Practices

Sanding Screen vs. Sandpaper for Hardwood Floors: Which is Best? When you're tackling hardwood floor projects, choosing the right abrasive is crucial for achieving a smooth, professional finish. Both sanding

Paper Backing vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper Back vs. Mesh Sanding Discs: Which One Should You Pick? Choosing the right sanding disc backing can significantly impact your project's efficiency and finish quality. Paper-backed discs are a

Sanding Mesh vs Paper: Which is More Economical and Better?

Is Sanding Mesh More Economical Than Sandpaper? Comparing Abrasive Costs When stocking up on abrasives, cost is always a factor. Paper sandpaper has traditionally been the standard, but newer mesh

Sanding Nets & Screens Use Cases: When to Choose Mesh Abrasives

Sanding Nets and Screens: What Are Their Best Use Cases? When you encounter sanding nets or screens, you might wonder where they fit into your sanding projects. Unlike traditional solid-backed