How is Abrasive Paper Made? Unveiling the Sandpaper Process

You use it to smooth wood, metal, or other surfaces, but have you ever wondered how that sheet of abrasive paper actually gets made? It’s a fascinating process with several key steps.

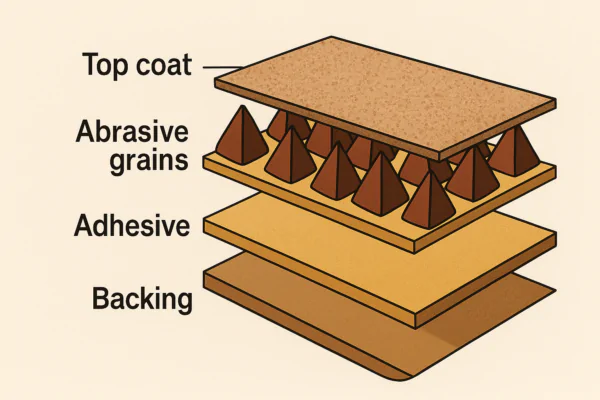

Abrasive paper, commonly known as sandpaper, is made by bonding abrasive grains to a backing material using adhesive. The manufacturing process involves preparing the backing, applying adhesive, electrostatically applying the abrasive grains, and then curing and finishing the product.

The different layers that make up a sheet of sandpaper.

Understanding how sandpaper is made gives you a better appreciation for the quality and characteristics that make different types suitable for different tasks. It’s more than just gluing sand onto paper!

How to Make Abrasive Paper?

While you won’t be making industrial-scale abrasive paper at home, knowing the basic steps gives insight into the manufacturing process. So, how is it done in a factory setting?

Making abrasive paper on an industrial scale involves a continuous web process where a large roll of backing material is fed through a series of stations. Adhesive is applied, abrasive grains are added, and the product is then dried and cut to size. NOVOGRIT utilizes advanced manufacturing processes to ensure high-quality production.

An industrial line producing abrasive paper.

The process begins with a large roll of the chosen backing material, which could be paper, cloth, film, or fiber. This material is unwound and moves along a conveyor system. The first step is applying the "make coat," which is a layer of adhesive that will hold the abrasive grains. This adhesive is carefully applied evenly across the backing. While the make coat is still wet, the backing passes through an electrostatic field. Abrasive grains are dropped into this field, and the electrostatic charge causes the grains to align themselves and stand upright on the adhesive-coated backing. This orientation ensures that the sharpest point of the grain is facing outwards, allowing for more efficient cutting. After the abrasive grains are in place, a second layer of adhesive, called the "size coat," is applied. This coat further anchors the grains and adds durability to the finished product. The coated material then goes through a curing process, often involving ovens, to fully dry and harden the adhesive. The final product is a large roll of abrasive material, which is then converted into different forms like sheets, discs, belts, or rolls by cutting and punching according to the desired product. Quality control is performed throughout the process to ensure consistent grit size, grain distribution, and bond strength, which are key characteristics of high-performance abrasives like those produced by NOVOGRIT.

How are Abrasives Made?

Sandpaper uses abrasive grains to do the work. But where do these hard, sharp particles come from and how are they manufactured?

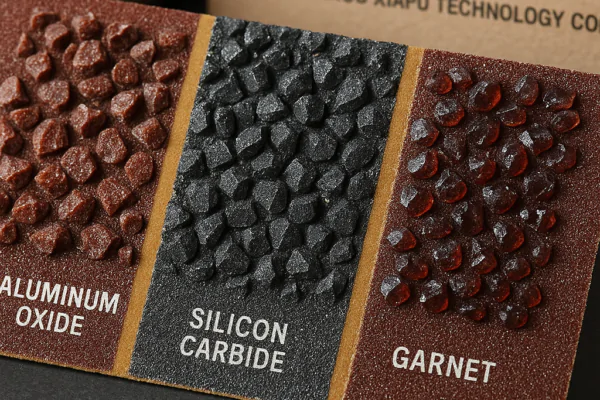

Abrasive grains used in sandpaper are typically synthetically manufactured materials known for their hardness and sharp edges. Common types include aluminum oxide, silicon carbide, and ceramic alumina. These are produced through high-temperature processes or chemical reactions and then crushed and graded by size.

Microscopic view of abrasive grains.

Aluminum oxide is one of the most common abrasives for sandpaper. It’s produced by fusing bauxite ore in an electric arc furnace at very high temperatures (over 2000°C). The molten material is allowed to cool and solidify, forming a hard, crystalline mass. This mass is then crushed, and the resulting particles are sorted by size to create different grit levels. Silicon carbide is even harder than aluminum oxide and is produced by heating silica sand and carbon (often in the form of petroleum coke or anthracite coal) in a high-temperature electric resistance furnace. This process creates silicon carbide crystals, which are then crushed and graded. Ceramic alumina is a newer type of abrasive and is known for its extreme toughness and longevity. It’s often made through a seeded gel process, where a gel containing aluminum oxide particles is sintered at high temperatures to form a microcrystalline structure that is very hard and fractures in a controlled way, exposing new sharp edges as it wears. The raw abrasive material, regardless of type, is crushed and then put through a series of sieves to separate the particles into specific size ranges, corresponding to the different sandpaper grit numbers. Finer grits have smaller particles, and coarser grits have larger particles. The quality and consistency of these abrasive grains are critical to the performance of sandpaper, and companies like NOVOGRIT source or produce high-quality grains for their products.

What are the Raw Materials for Sandpaper?

Sandpaper isn’t just one thing; it’s a combination of different materials. What exactly goes into making it?

The primary raw materials for sandpaper are the backing material, the adhesive that binds the grains, and the abrasive grains themselves. The specific type of these materials will vary depending on the intended application and desired performance characteristics of the sandpaper.

Different materials used for sandpaper backing.

Let’s break down the key components. The backing material provides the base for the sandpaper. Different materials offer different levels of flexibility, durability, and resistance to tearing or stretching. Paper is a common and cost-effective backing, suitable for general purpose sanding, especially in sheets. Cloth backing is much stronger and more flexible, making it ideal for sanding belts and discs used with power tools where durability is important. Polyester or cotton cloth are often used. Film backing, made from materials like polyester, is very uniform in thickness and tear-resistant, often used for precision sanding or applications requiring a very even finish, such as automotive refinishing with NOVOGRIT film sanding discs. Fiber backing is a thick, stiff paper-like material often used for resin fiber discs for heavy-duty grinding. The adhesive is crucial for bonding the abrasive grains to the backing and for holding them in place during sanding. Historically, natural glues like hide glue were used, but modern sandpaper typically uses synthetic resins, such as phenolic resin or epoxy resin, which are much more durable and heat-resistant. Some specialized sandpapers might use different adhesives for waterproof properties (for wet sanding). Finally, the abrasive grains, as discussed before, are the cutting particles. The choice of abrasive (aluminum oxide, silicon carbide, ceramic) depends on the material being sanded and the desired aggressiveness and longevity. These raw materials are carefully selected and processed by manufacturers like Hangzhou sharp Technology Co., Ltd., the company behind the NOVOGRIT brand, to produce high-quality abrasive products.

How is it Made: Sandpaper Episode?

Imagine watching an episode of a "How It’s Made" show focusing on sandpaper. What steps would they highlight?

An episode on how sandpaper is made would likely showcase the continuous web manufacturing line, detailing the unrolling of the backing material, the application of the make coat adhesive, the fascinating electrostatic application of abrasive grains, the addition of the size coat, the curing process in large ovens, and the final conversion into various product formats like sheets, discs, and belts.

Large rolls of sandpaper being cut in a factory.

Such an episode would probably start by introducing the basic function of sandpaper and then take viewers inside a modern abrasive manufacturing facility, like ours at Hangzhou sharp Technology Co., Ltd. They would show large rolls of different backing materials (paper, cloth, film) being loaded onto machinery. The camera would follow the backing as it moves along, showing the precise application of the initial adhesive layer. The segment on the electrostatic grain application would be particularly interesting, demonstrating how the charged particles literally jump onto the adhesive-coated backing and stand on end. This is a key step that influences the sandpaper’s cutting efficiency. The application of the second layer of adhesive would be shown, followed by the material entering long ovens for the curing process, where the adhesive hardens. The segment would likely explain the importance of temperature and time in the curing process. Finally, the large rolls of finished abrasive material would be shown being fed into converting machines that cut and shape them into the familiar products you see in stores: sheets, discs with or without holes for dust collection, sanding belts, and rolls. They might also touch upon quality control procedures, such as checking the grit size distribution and testing the flexibility and durability of the finished product. Showing the scale of the operation and the technology involved in producing something as seemingly simple as sandpaper would be the highlight of the episode.

Conclusion

Making abrasive paper is a sophisticated industrial process that involves carefully combining backing materials, adhesives, and abrasive grains. From the initial raw materials to the final cutting and shaping, each step is important in creating high-performance abrasives like those from NOVOGRIT that help you achieve smooth finishes.

You may also be interested in:

What is the difference between zirconium, ceramic, and aluminum oxide abrasives?

Choosing the right abrasive can be confusing. Using the wrong one wastes time, ruins your workpiece, and costs you money. Let’s make the choice simple for you. The main difference

Best Sandpaper for Aluminum: NOVOGRIT's Guide to Flawless Finishes

What is the Best Type of Sandpaper to Use on Aluminum? Do you find yourself frustrated by sandpaper that gums up instantly when you try to smooth aluminum? It is

Best Sandpaper for Paint Removal: Grits, Types, & Tips | NOVOGRIT

What is the Best Sandpaper for Removing Paint? Are you tired of staring at chipped, peeling paint on your furniture, walls, or even your car? It's a common problem, and

Automotive Wet Sanding: Supplies, Liquids & Best Sandpaper

Automotive Wet Sanding Supplies: What Do You Really Need? Wet sanding is a crucial technique in automotive refinishing, used to achieve a flawlessly smooth surface before painting or polishing. Unlike

Best Sandpaper for Paint Removal & Grit Guide

What Is the Best Sandpaper for Removing Paint? Removing old paint can be a tedious job, but using the right sandpaper makes all the difference. It's not just about grit;

Hardwood Floor Sanding: Screen vs. Sandpaper & Best Practices

Sanding Screen vs. Sandpaper for Hardwood Floors: Which is Best? When you're tackling hardwood floor projects, choosing the right abrasive is crucial for achieving a smooth, professional finish. Both sanding

Paper Backing vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper Back vs. Mesh Sanding Discs: Which One Should You Pick? Choosing the right sanding disc backing can significantly impact your project's efficiency and finish quality. Paper-backed discs are a

Sanding Mesh vs Paper: Which is More Economical and Better?

Is Sanding Mesh More Economical Than Sandpaper? Comparing Abrasive Costs When stocking up on abrasives, cost is always a factor. Paper sandpaper has traditionally been the standard, but newer mesh

Sanding Nets & Screens Use Cases: When to Choose Mesh Abrasives

Sanding Nets and Screens: What Are Their Best Use Cases? When you encounter sanding nets or screens, you might wonder where they fit into your sanding projects. Unlike traditional solid-backed