Essential Tools for Stainless Buffing Success: Getting the Right Shine

Buffing stainless steel isn’t something you do with just one tool. Getting that smooth, reflective surface requires a combination of equipment, each playing a specific role in the process. Having the right tools makes a huge difference in the final result and how easy the job is.

Essential tools for stainless steel buffing success include power tools like angle grinders, orbital sanders, or dedicated buffing machines, along with a variety of abrasive products such as sanding discs or belts in different grits, and a selection of buffing wheels and compounds matched to the desired finish and stage of the buffing process. Safety gear is also absolutely critical.

Various tools and supplies needed for buffing stainless steel.

Equipping yourself with the right tools and understanding how to use them correctly is fundamental to achieving a professional-looking finish on your stainless steel projects.

What tool to use to polish stainless steel?

When you need to polish stainless steel, particularly to a high shine, what power tool is typically used?

To polish stainless steel, especially to a high gloss, power tools like variable-speed angle grinders fitted with appropriate backing pads and sanding discs, random orbital sanders for finer grits, or dedicated bench or pedestal buffing machines with buffing wheels and compounds are commonly used. The choice depends on the size and shape of the workpiece and the desired level of finish.

A power tool used for polishing stainless steel surfaces.

The right power tool provides the speed and consistency needed to effectively work the surface of the stainless steel with abrasives and compounds. For initial grinding and shaping, or for removing heavy scratches, a standard angle grinder with grinding discs or coarse flap discs is often used, but this is more material removal than polishing. For the polishing process itself, especially the abrasive steps leading up to buffing, a variable-speed angle grinder is very versatile. You can fit it with a rubber or plastic backing pad and use sanding discs in a wide range of grits. The variable speed control is important because different grits and stages of polishing may require different speeds. Random orbital sanders are excellent for working on flat surfaces with finer grits, providing a smooth finish and helping to prevent swirl marks. For the final buffing stages, dedicated buffing machines, either bench-mounted or pedestal style, are ideal. These machines have spindles designed to hold buffing wheels securely and operate at speeds suitable for buffing. Handheld buffers or polishers, similar to those used for car detailing, can also be adapted for stainless steel buffing, especially on larger or irregularly shaped pieces. Regardless of the tool, using the right type and quality of abrasive accessories, like durable NOVOGRIT sanding discs that resist clogging, is crucial for efficient material removal and a consistent finish.

What is the best speed for polishing stainless steel?

Does the speed of the tool matter when polishing stainless steel, and if so, what is the optimal range?

The best speed for polishing stainless steel varies depending on the stage of the process and the abrasive or compound being used. Generally, slower speeds (around 1,000-2,000 RPM) are better for initial grinding and coarser grits to avoid overheating and discoloration, while higher speeds (up to 3,000-5,000 RPM or more) are often used for finer polishing and buffing stages to achieve a high shine.

Adjusting the speed setting on a polishing tool.

Speed plays a significant role in how abrasives and buffing compounds interact with the stainless steel surface. When using coarser abrasives to remove material and shape the surface, too high a speed can generate excessive heat. Stainless steel is sensitive to heat, and overheating can lead to heat tint (discoloration) or even warping of the metal. Therefore, using slower speeds and applying moderate pressure is generally recommended for the initial grinding and coarser sanding steps. As you move to finer grits and the polishing stages with compounds, higher speeds are often beneficial. The friction generated at higher speeds helps the fine abrasive particles in the compound work more effectively to refine the surface and create a high luster. However, even at higher speeds, excessive pressure or dwelling in one spot for too long can still cause overheating and discoloration. It is a balance between speed, pressure, and movement. Variable speed tools are highly recommended because they allow you to adjust the speed according to the specific abrasive, compound, and stage of polishing. Always refer to the manufacturer’s recommendations for the specific abrasive or buffing product you are using, as they may have optimal speed ranges. Using high-performance abrasives like NOVOGRIT can sometimes allow for more efficient work at lower speeds, further minimizing the risk of heat damage.

Why is my stainless steel not shiny?

If you’ve tried to polish stainless steel but it’s not achieving the desired shine, what could be the reasons?

Stainless steel may not become shiny if the surface preparation steps were insufficient, meaning coarser scratches were not fully removed before attempting to polish. Other reasons include using the wrong type of buffing compound or wheel for the final polishing stage, not using enough compound, applying insufficient pressure, or not buffing for long enough to achieve the desired level of reflectivity.

A stainless steel surface that lacks shine.

The most common reason for a lack of shine is insufficient surface preparation. Buffing compounds, especially polishing compounds, are designed to refine a surface that is already very smooth from abrasive sanding. They are not designed to remove deep scratches. If you skip grits in the sanding process or do not fully remove the scratch pattern from the previous grit before moving on, those deeper scratches will remain visible and prevent the surface from becoming truly reflective. Think of it like trying to paint a smooth finish over a rough, unsanded surface – the roughness will show through. The final abrasive grit used before buffing should leave a surface that appears almost polished itself, even if it’s a dull polish. Another issue can be using the wrong buffing compound or wheel. Using a cutting compound for the final stage, for example, will leave a refined but not mirror-like finish. Not applying enough buffing compound to the wheel, or not replenishing it as it gets used up, means there aren’t enough abrasive particles to do the work. Insufficient pressure or not buffing the surface for long enough are also common causes; achieving a high shine takes time and consistent effort across the entire surface. Finally, ensure the stainless steel is thoroughly cleaned between abrasive steps and before buffing to remove any debris that could cause scratches during the next stage. Starting with high-quality NOVOGRIT abrasives ensures you build a proper foundation for the subsequent polishing steps.

What is the best rpm for polishing metal?

Considering various metals, is there a general rule of thumb or range for the best RPM when polishing?

The best RPM range for polishing metal is not a single fixed number, as it depends on the specific metal (like stainless steel, aluminum, brass), the type of abrasive or compound, the size of the buffing wheel, and the desired finish. However, a common range for metal polishing and buffing often falls between 2,000 and 5,000 RPM, with softer metals or coarser abrasives sometimes requiring lower speeds, and harder metals or finer polishing requiring higher speeds.

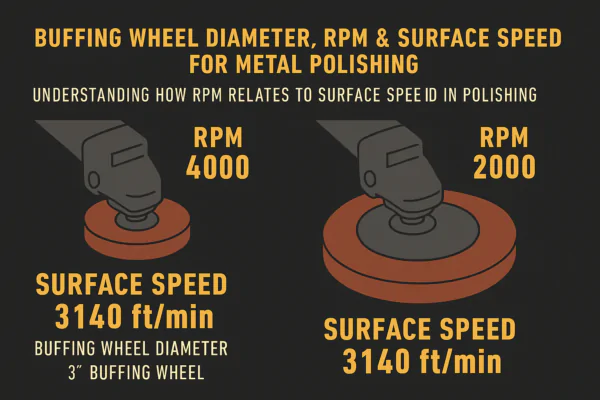

Understanding how RPM relates to surface speed in polishing.

When talking about polishing, what is often most relevant is the surface speed of the abrasive or buffing wheel against the workpiece, measured in feet per minute (SFPM) or meters per second. This surface speed is determined by the RPM of the tool and the diameter of the wheel. A larger diameter wheel spinning at the same RPM will have a higher surface speed than a smaller wheel. Different metals and different stages of polishing perform best within specific surface speed ranges. While providing exact SFPM values for every scenario is complex, translating these to RPM for common wheel sizes gives a useful range. For general metal polishing and buffing with wheels typically between 4 and 8 inches in diameter, RPMs from 2,000 to 5,000 are common. Softer metals like aluminum might require slightly lower speeds and lighter pressure to avoid burning or excessive material removal. Harder metals like stainless steel can generally handle higher speeds, especially during the final polishing stages with fine compounds, which benefit from the increased friction and heat generated at higher speeds to activate the compound and refine the surface. However, as mentioned regarding stainless steel, excessive heat must still be avoided with all metals to prevent discoloration or damage. Always test on a scrap piece first to find the optimal speed, pressure, and compound combination for the specific metal and desired finish. Using high-quality, heat-resistant abrasives like NOVOGRIT also helps manage heat during the sanding steps.

Conclusion

Achieving successful stainless steel buffing relies on having the right tools, including power tools with variable speed, appropriate abrasives for surface preparation, and matching buffing wheels and compounds for the polishing stages. Understanding the role of speed and avoiding common mistakes like insufficient preparation are key to getting a perfect, shiny finish.

You may also be interested in:

What is the difference between zirconium, ceramic, and aluminum oxide abrasives?

Choosing the right abrasive can be confusing. Using the wrong one wastes time, ruins your workpiece, and costs you money. Let’s make the choice simple for you. The main difference

Best Sandpaper for Aluminum: NOVOGRIT's Guide to Flawless Finishes

What is the Best Type of Sandpaper to Use on Aluminum? Do you find yourself frustrated by sandpaper that gums up instantly when you try to smooth aluminum? It is

Best Sandpaper for Paint Removal: Grits, Types, & Tips | NOVOGRIT

What is the Best Sandpaper for Removing Paint? Are you tired of staring at chipped, peeling paint on your furniture, walls, or even your car? It's a common problem, and

Automotive Wet Sanding: Supplies, Liquids & Best Sandpaper

Automotive Wet Sanding Supplies: What Do You Really Need? Wet sanding is a crucial technique in automotive refinishing, used to achieve a flawlessly smooth surface before painting or polishing. Unlike

Best Sandpaper for Paint Removal & Grit Guide

What Is the Best Sandpaper for Removing Paint? Removing old paint can be a tedious job, but using the right sandpaper makes all the difference. It's not just about grit;

Hardwood Floor Sanding: Screen vs. Sandpaper & Best Practices

Sanding Screen vs. Sandpaper for Hardwood Floors: Which is Best? When you're tackling hardwood floor projects, choosing the right abrasive is crucial for achieving a smooth, professional finish. Both sanding

Paper Backing vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper Back vs. Mesh Sanding Discs: Which One Should You Pick? Choosing the right sanding disc backing can significantly impact your project's efficiency and finish quality. Paper-backed discs are a

Sanding Mesh vs Paper: Which is More Economical and Better?

Is Sanding Mesh More Economical Than Sandpaper? Comparing Abrasive Costs When stocking up on abrasives, cost is always a factor. Paper sandpaper has traditionally been the standard, but newer mesh

Sanding Nets & Screens Use Cases: When to Choose Mesh Abrasives

Sanding Nets and Screens: What Are Their Best Use Cases? When you encounter sanding nets or screens, you might wonder where they fit into your sanding projects. Unlike traditional solid-backed