Choosing the Right Sanding Belts for You: Abrasives, Grits, and Backings

Picking the right sanding belt can feel overwhelming with so many options available. The material you’re working on, the desired finish, and the type of sander you have all play a role in making the best choice. Getting it wrong means wasted time and poor results.

Choosing the right sanding belts involves understanding the abrasive material type (like aluminum oxide, zirconia, or ceramic), the grit size (from coarse for stock removal to very fine for finishing), the belt backing material (like paper, cloth, or film), and considering features like splice type and anti-clogging coatings, all matched to the specific application and material being sanded.

A visual guide to the variety in sanding belts.

Making an informed choice ensures you work efficiently, achieve the desired finish, and get the best value from your abrasive belts.

What is the best sandpaper for belts?

When it comes to sanding belts, what type of sandpaper or abrasive is generally considered the best, and for what applications?

The "best" abrasive for sanding belts depends on the material being sanded. Aluminum oxide is a versatile and cost-effective choice for general wood sanding. Zirconia is excellent for aggressive grinding on wood and metal due to its durability and self-sharpening properties. Ceramic abrasives are the top choice for demanding metalworking applications and hard woods, offering the longest life and fastest cut rate.

Different abrasive grain types used in sanding belts.

Understanding the properties of different abrasive types is key to selecting the most effective belt for your task. Aluminum oxide is a very common and affordable abrasive. It’s tough and fractures to create new cutting edges, making it suitable for a wide range of materials, particularly wood and some metals. It’s a good all-around choice for general sanding tasks. Zirconia alumina (often called zirconia) is harder and more durable than aluminum oxide. It’s engineered to fracture in a way that constantly exposes sharp new cutting points, making it "self-sharpening." This property makes zirconia belts ideal for more aggressive stock removal on both wood and metal, and they have a longer working life than aluminum oxide, especially under high pressure. Ceramic alumina is the newest and most advanced abrasive type. It’s the hardest and toughest, designed for the most demanding applications. Ceramic grains also micro-fracture to stay sharp, but they do so in a more controlled way than zirconia, leading to extremely long life and a very high, consistent cut rate, especially on hard metals like stainless steel. For tasks like heavy metal grinding or shaping very hard wood, ceramic belts are often worth the higher cost because they work faster and last much longer. For general purposes and softer woods, aluminum oxide is perfectly adequate. For moderate to heavy stock removal on wood or metal, zirconia offers a good balance of performance and cost. For top performance on hard materials, ceramic is the way to go. Knowing which abrasive is designed for which task helps you pick the "best" belt for your specific needs.

What is the difference between P80 and 80 grit sandpaper?

Grit numbers can be confusing; is there a difference between a grit number preceded by "P" and one that isn’t?

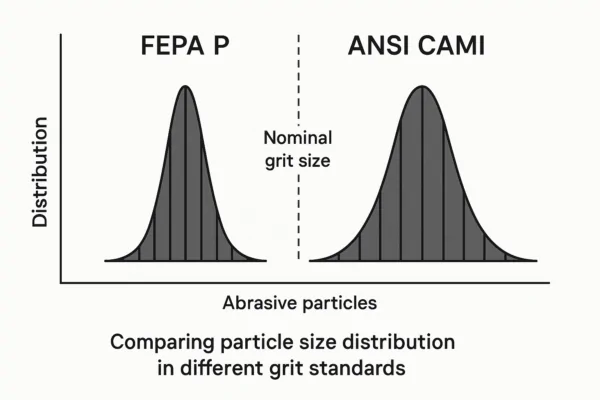

Yes, there is a difference between grit numbers preceded by "P" (like P80) and those without the "P" (like 80 grit). The "P" indicates that the sandpaper grit size conforms to the European P-scale grading system (FEPA P), which has slightly different specifications and stricter tolerance ranges for the abrasive particle size distribution compared to older or other non-P systems (like the ANSI/CAMI system used in North America).

Comparing particle size distribution in different grit standards.

Understanding grit grading is important for predicting the finish you will get. The purpose of grit grading systems is to classify the size of the abrasive particles on the sandpaper or sanding belt. Coarser grits (lower numbers) have larger particles and remove material quickly, leaving a rougher surface. Finer grits (higher numbers) have smaller particles, remove less material, and leave a smoother finish. The "P" system, or FEPA P, was developed in Europe and is widely used internationally. It specifies a tighter range for the size of the abrasive particles within a given grit number. This means that a P80 grit sandpaper or belt will have a more uniform particle size distribution than a standard 80 grit from a non-P system. A tighter tolerance on particle size leads to a more consistent scratch pattern and a more predictable finish. While an 80 grit and a P80 grit may feel similar and perform similarly for rough work, the difference becomes more noticeable as you move to finer grits where surface finish is critical. Using the P-scale, you can expect a P220 to consistently leave a finer scratch pattern than a non-P 220, making the progression through grits more reliable for achieving a smooth final surface. Many quality abrasive manufacturers, including those producing high-performance belts and discs like NOVOGRIT, adhere to the P-scale for better consistency.

What is the best belt size for a belt sander?

Belt sanders come in various sizes; how do you determine the best belt size for your specific sander?

The best belt size for a belt sander is determined by the specifications of the sander itself. Belt sanders are designed to use belts of a very specific width and length. You must match the belt size exactly to what your sander is rated for, as using an incorrect size will prevent the belt from fitting or tracking properly, potentially damaging the sander or causing safety issues.

Matching the belt size to the belt sander’s requirements.

Unlike some tools where accessories might have a range of compatibility, belt sanders are very particular about belt size. The length of the belt is crucial because it has to fit snugly around the drive roller and the idler roller(s), allowing for proper tensioning and tracking. The width of the belt must also match the width of the sander’s platen and rollers. Using a belt that is too short simply won’t fit. A belt that is too long cannot be properly tensioned and will slip. A belt that is too wide will rub against the sander housing, and one that is too narrow won’t cover the full width of the platen, making it difficult to sand evenly. The required belt size is always listed on the sander itself, usually on a label or in the user manual. Common sizes for portable belt sanders include 3×18 inches, 3×21 inches, and 4×24 inches. Larger industrial belt grinders might use much larger belts, often specified by both width and length in inches or millimeters. Always check your sander’s specifications before purchasing replacement belts. Quality belt manufacturers produce belts in standard sizes to fit most popular sanders.

How many inches wide is a sanding belt?

Sanding belts come in various widths. What are the common widths you’ll encounter, and why are different widths used?

Sanding belts are available in a range of widths, typically from 1/2 inch (for detail sanders) up to several inches (for portable and industrial belt sanders), and even wider for specialized wide-belt sanders. Common widths for portable belt sanders include 3 inches and 4 inches. The width used depends on the size of the area being sanded, the power of the sander, and the need for detail work versus rapid material removal over a large area.

Various widths of sanding belts.

The width of a sanding belt directly impacts the area it covers and the speed at which you can remove material or achieve a finish. Narrow belts, like those around 1/2 inch or 1 inch wide, are typically used on small detail sanders or specialized pneumatic tools. These are great for sanding in tight spaces, shaping small parts, or doing detailed work where precision is needed. Portable belt sanders designed for general woodworking or moderate material removal usually use belts in the 3-inch or 4-inch width range. A wider belt covers more surface area with each pass, allowing you to sand larger boards or panels more quickly. A wider belt also distributes the sanding pressure over a larger area, which can lead to a smoother finish, although it requires a more powerful motor in the sander to drive it effectively. Industrial belt grinders and specialized metal finishing machines often use belts that are several inches wide, designed for high-speed, heavy-duty stock removal or finishing on large parts. Wide-belt sanders, used in furniture manufacturing and panel processing, can use belts that are many feet wide to sand entire sheets of material at once. The width of the belt is a functional characteristic chosen by the tool designer to match the intended application and power of the sander.

Conclusion

Choosing the right sanding belts requires considering the abrasive type for the material, understanding grit grading systems like the P-scale for consistent finishes, and always matching the belt size precisely to your sander’s specifications. Paying attention to these details ensures efficient sanding and quality results.

You may also be interested in:

What is the difference between zirconium, ceramic, and aluminum oxide abrasives?

Choosing the right abrasive can be confusing. Using the wrong one wastes time, ruins your workpiece, and costs you money. Let’s make the choice simple for you. The main difference

Best Sandpaper for Aluminum: NOVOGRIT's Guide to Flawless Finishes

What is the Best Type of Sandpaper to Use on Aluminum? Do you find yourself frustrated by sandpaper that gums up instantly when you try to smooth aluminum? It is

Best Sandpaper for Paint Removal: Grits, Types, & Tips | NOVOGRIT

What is the Best Sandpaper for Removing Paint? Are you tired of staring at chipped, peeling paint on your furniture, walls, or even your car? It's a common problem, and

Automotive Wet Sanding: Supplies, Liquids & Best Sandpaper

Automotive Wet Sanding Supplies: What Do You Really Need? Wet sanding is a crucial technique in automotive refinishing, used to achieve a flawlessly smooth surface before painting or polishing. Unlike

Best Sandpaper for Paint Removal & Grit Guide

What Is the Best Sandpaper for Removing Paint? Removing old paint can be a tedious job, but using the right sandpaper makes all the difference. It's not just about grit;

Hardwood Floor Sanding: Screen vs. Sandpaper & Best Practices

Sanding Screen vs. Sandpaper for Hardwood Floors: Which is Best? When you're tackling hardwood floor projects, choosing the right abrasive is crucial for achieving a smooth, professional finish. Both sanding

Paper Backing vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper Back vs. Mesh Sanding Discs: Which One Should You Pick? Choosing the right sanding disc backing can significantly impact your project's efficiency and finish quality. Paper-backed discs are a

Sanding Mesh vs Paper: Which is More Economical and Better?

Is Sanding Mesh More Economical Than Sandpaper? Comparing Abrasive Costs When stocking up on abrasives, cost is always a factor. Paper sandpaper has traditionally been the standard, but newer mesh

Sanding Nets & Screens Use Cases: When to Choose Mesh Abrasives

Sanding Nets and Screens: What Are Their Best Use Cases? When you encounter sanding nets or screens, you might wonder where they fit into your sanding projects. Unlike traditional solid-backed