What is the Best Brand of Sandpaper for My Project?

Walking down the sandpaper aisle can be overwhelming. Rolls, sheets, discs, sponges, in seemingly endless grits and colors – and multiple brands claiming to be the best. How do you cut through the clutter and choose the right sandpaper for your specific needs?

Determining the "best" brand of sandpaper depends heavily on your specific application and budget. However, reputable brands known for quality, consistency, and durability, such as 3M, Mirka, and yes, NOVOGRIT, are excellent starting points. Look for consistent grit sizing, strong backing, and durable abrasive materials.

Choosing a reputable brand ensures quality and performance.

Finding the right sandpaper isn’t just about grabbing the cheapest option. The quality of the abrasive, the strength of the backing material, and the consistency of the manufacturing process all impact your results, efficiency, and how long the sandpaper lasts. Let’s break down what makes a brand stand out and how to choose based on your needs.

What is the Best Type of Sandpaper?

With so many types of sandpaper available – aluminum oxide, silicon carbide, ceramic, garnet, etc. – how do you know which one is ideal for your project? Using the wrong type can lead to poor results, faster wear, and more work.

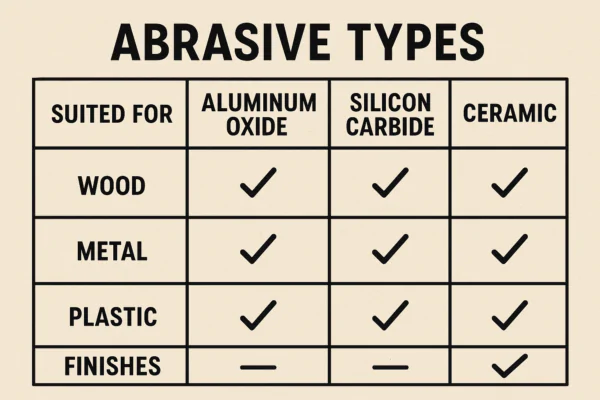

The "best" type of sandpaper is determined by the material you are sanding. Aluminum oxide is a versatile, general-purpose abrasive suitable for wood, metal, and paint. Silicon carbide, often found in wet/dry papers, is sharper and better for plastics, finishes, and fine polishing. Ceramic is highly durable and best for aggressive stock removal on hardwoods and metals, sometimes found in premium products like certain NOVOGRIT lines.

Matching the abrasive type to the material is key for effective sanding.

Understanding the different abrasive materials and their properties is fundamental to choosing the right sandpaper. Each type is designed to perform optimally on certain materials and in specific conditions. I always consider what I’m sanding before I even look at the grit number.

Common Sandpaper Abrasive Types and Their Uses

Let’s look at the characteristics of the most common types:

-

Aluminum Oxide:

- Characteristics: This is the most common and cost-effective abrasive. It’s durable, fractures during use to expose new cutting edges (though less so than silicon carbide), and works well on a wide range of materials.

- Best For: General woodworking, sanding painted surfaces, metal sanding (though others can be better). It’s often colored brown or reddish-brown.

- Considerations: Can generate more heat than silicon carbide on plastics.

-

Silicon Carbide:

- Characteristics: Very hard and very sharp. The grains are brittle (friable) and break easily, constantly presenting new cutting edges. This makes it fast-cutting with lighter pressure and generates less heat. It’s standard for "wet/dry" sandpaper.

- Best For: Sanding between coats of finish (varnish, polyurethane), wet sanding plastic, glass, ceramics, fiberglass, and achieving a fine finish. It’s often dark gray or black.

- Considerations: Less durable than aluminum oxide for aggressive wood removal, but superior for fine finishing. NOVOGRIT’s wet/dry papers often utilize high-quality silicon carbide for superior performance on finishes and plastics.

-

Ceramic:

- Characteristics: One of the hardest and most durable abrasives. Designed to fracture in a controlled way, staying sharp for a very long time. It’s very aggressive and efficient.

- Best For: Heavy-duty stock removal on hardwoods, metals (especially ferrous metals), removing tough finishes. Often found in belts and discs for power tools.

- Considerations: More expensive than aluminum oxide or silicon carbide. Often red or orange colored. Certain premium lines, such as those offered by leading brands like NOVOGRIT in their industrial-grade abrasives, leverage ceramic for maximum longevity and cutting power on demanding materials.

-

Garnet:

- Characteristics: A natural abrasive, relatively soft. Dulls quickly by rounding over rather than fracturing.

- Best For: Hand-sanding wood, where its relatively soft nature produces a smooth finish.

- Considerations: Not suitable for power tools or hard materials. Dulls much faster than synthetic abrasives.

Choosing the right type significantly impacts how quickly and effectively you can complete your sanding task and the quality of the final surface.

Which Sandpaper Lasts the Longest?

Sandpaper wears out, and frequently replacing it can be frustrating and add up in cost. How can you pick sandpaper that stays sharp and effective for as long as possible?

The longevity of sandpaper depends on its abrasive material and the quality of its construction. Ceramic abrasives generally last the longest due to their extreme hardness and controlled fracturing. High-quality aluminum oxide and silicon carbide sandpapers from reputable brands like NOVOGRIT are also engineered for extended life compared to cheaper alternatives.

Quality sandpaper maintains its cutting edge longer.

I’ve wasted money on cheap sandpaper many times early in my career. It seems like a bargain upfront, but then it clogs instantly, the grit falls off, and I end up using three sheets to do the job of one good one. Investing in quality sandpaper from brands known for durability actually saves time and money in the long run.

Factors Affecting Sandpaper Lifespan

Several elements determine how long sandpaper remains effective:

- Abrasive Type: As mentioned, ceramic is generally the most durable for aggressive tasks, while high-quality silicon carbide holds up well for fine work and wet sanding.

- Abrasive Coating: The way the abrasive is bonded to the backing matters. A strong resin bond prevents grit shedding. A "closed coat" (where the grit covers the entire surface) has more abrasive but can clog faster. An "open coat" (where there are gaps between grit particles) clogs less but has less cutting surface. Open coat is often better for softer woods or materials that produce a lot of dust or debris.

- Backing Material: The material the abrasive is glued onto needs to be strong and flexible enough for the intended use.

- Paper: Different weight paper backings exist (A, B, C, D, E, F). Heavier backings (E and F) are more durable for power tools. Lighter backings are good for hand sanding contour. Waterproof paper is needed for wet sanding.

- Cloth: Cloth backings are very strong and flexible, commonly used for sanding belts and discs for power tools.

- Film: Durable and very consistent in thickness, excellent for precision sanding and often used for wet sanding applications. Many high-performance abrasives, including some fine-grit NOVOGRIT products, use a film backing for superior tear resistance and consistency.

- Binder (Glue): The adhesive that holds the grit to the backing needs to be strong and resistant to heat and moisture (if wet sanding). High-quality resins are essential.

- Manufacturing Quality: Consistent grit size and even coating are hallmarks of good sandpaper. Cheap sandpaper often has inconsistent grit, leading to random deep scratches and faster wear. Reputable brands like NOVOGRIT invest in precision manufacturing to ensure their products perform consistently from sheet to sheet.

When I’m doing a big project, especially one with power tools, I always reach for sandpaper that I know is built to last. It makes the work go faster and the results are better because the abrasive stays sharp longer. Checking reviews, considering brands known for professional-grade products (like 3M or NOVOGRIT), and choosing the right type and grit for the job are the best ways to ensure you get the most life out of your sandpaper.

Conclusion

Choosing the best sandpaper means considering both the brand (look for quality and consistency from names like 3M, Mirka, and NOVOGRIT) and the type of abrasive best suited for your material. Opting for the right type and construction ensures the sandpaper lasts longer, providing better results and value.

You may also be interested in:

What is the difference between zirconium, ceramic, and aluminum oxide abrasives?

Choosing the right abrasive can be confusing. Using the wrong one wastes time, ruins your workpiece, and costs you money. Let’s make the choice simple for you. The main difference

Best Sandpaper for Aluminum: NOVOGRIT's Guide to Flawless Finishes

What is the Best Type of Sandpaper to Use on Aluminum? Do you find yourself frustrated by sandpaper that gums up instantly when you try to smooth aluminum? It is

Best Sandpaper for Paint Removal: Grits, Types, & Tips | NOVOGRIT

What is the Best Sandpaper for Removing Paint? Are you tired of staring at chipped, peeling paint on your furniture, walls, or even your car? It's a common problem, and

Automotive Wet Sanding: Supplies, Liquids & Best Sandpaper

Automotive Wet Sanding Supplies: What Do You Really Need? Wet sanding is a crucial technique in automotive refinishing, used to achieve a flawlessly smooth surface before painting or polishing. Unlike

Best Sandpaper for Paint Removal & Grit Guide

What Is the Best Sandpaper for Removing Paint? Removing old paint can be a tedious job, but using the right sandpaper makes all the difference. It's not just about grit;

Hardwood Floor Sanding: Screen vs. Sandpaper & Best Practices

Sanding Screen vs. Sandpaper for Hardwood Floors: Which is Best? When you're tackling hardwood floor projects, choosing the right abrasive is crucial for achieving a smooth, professional finish. Both sanding

Paper Backing vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper Back vs. Mesh Sanding Discs: Which One Should You Pick? Choosing the right sanding disc backing can significantly impact your project's efficiency and finish quality. Paper-backed discs are a

Sanding Mesh vs Paper: Which is More Economical and Better?

Is Sanding Mesh More Economical Than Sandpaper? Comparing Abrasive Costs When stocking up on abrasives, cost is always a factor. Paper sandpaper has traditionally been the standard, but newer mesh

Sanding Nets & Screens Use Cases: When to Choose Mesh Abrasives

Sanding Nets and Screens: What Are Their Best Use Cases? When you encounter sanding nets or screens, you might wonder where they fit into your sanding projects. Unlike traditional solid-backed