What Grit Sandpaper Should I Use on Metal?

Working with metal often requires sanding. It might be preparing a surface for paint, removing rust, or smoothing edges. Using the wrong sandpaper can damage your project. Knowing the right grit makes a big difference.

The right grit sandpaper for metal depends on the job. You start with a lower grit to remove material like rust or paint. You use higher grits to smooth the surface and prepare it for finishing. Always test on a hidden area first.

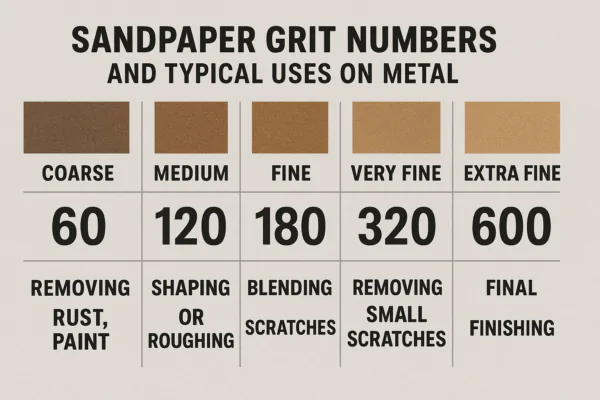

Different sandpaper grits shown on metal.

Choosing the right sandpaper is important for a good finish. It saves you time and effort. Let’s look at what makes sandpaper suitable for metal and how different grits work. We can make the job easier with the right tools.

What Sandpaper is Best for Metal?

Choosing the best sandpaper for metal can be confusing. There are many types available. Some work better than others on hard surfaces like metal. Knowing which type to pick is important for good results.

The best sandpaper for metal is usually made with aluminum oxide or zirconia alumina abrasives. These materials are tough and last a long time when sanding metal. Silicon carbide can also work but might not last as long on hard steel. Always look for sandpaper designed for metal or multi-surface use.

Using aluminum oxide sandpaper on metal.

When I first started working with metal, I used regular wood sandpaper. It clogged quickly and didn’t do much. A friend who works with cars told me about aluminum oxide sandpaper. It made a huge difference. It cut through paint and rust much faster. Brands like NOVOGRIT offer specialized abrasives. These are designed for tough jobs like sanding metal. Different types of sandpaper use different materials. The backing also matters. Paper backing is common. Cloth backing is more durable and flexible. It’s good for curves. Wet/dry sandpaper is also useful. You can use it with water or oil. This helps reduce dust and clogging. It also gives a finer finish. For heavy rust removal, you might even consider sanding discs with ceramic abrasives. These are very aggressive. They remove a lot of material fast. For general work on metal, aluminum oxide or zirconia alumina is usually the way to go.

What Sandpaper to Use to Rub Down Metal?

Rubbing down metal can mean different things. It might be removing old finishes, preparing for new ones, or just cleaning the surface. The right sandpaper depends on what you want to achieve. You need to match the grit and type to the task.

To rub down metal, you should start with a medium to coarse grit sandpaper. This removes surface imperfections like rust, paint, or scratches. Then, you gradually move to finer grits. This smooths the surface and prepares it for polishing or painting.

Rubbing down a rusty metal pipe with sandpaper.

If you are rubbing down metal to remove rust or paint, you need an aggressive grit. Start with something like 60 or 80 grit. This will cut through the old material fast. Make sure the sandpaper is designed for metal. Aluminum oxide or zirconia alumina is good. NOVOGRIT offers durable options that won’t wear out quickly on metal. After removing the main layer, move to a finer grit. Use 120 or 180 grit. This starts to smooth the surface. If you want a very smooth finish, continue with even finer grits. Go to 220, 320, or even higher. The goal is to remove the scratches from the previous grit. Each step makes the surface smoother. Always sand in a consistent direction. This helps achieve an even finish. For large areas, power tools can help. An orbital sander with the right disc is faster. Make sure you use discs designed for power sanding on metal. They usually have stronger backing and better adhesive. Sometimes, you might need to hand sand. This is for detailed areas or curves. Use flexible sandpaper or a sanding block. The right technique is as important as the right sandpaper. Apply even pressure. Don’t press too hard. Let the abrasive do the work.

What Grit Sandpaper Won’t Scratch Metal?

It seems like all sandpaper scratches metal, right? That’s kind of true, but it’s about the type of scratch and whether you can remove it later. The goal isn’t usually no scratches, but scratches fine enough that they disappear with subsequent steps or finishing.

No sandpaper grit will leave metal completely unscratched at a microscopic level. However, very fine grits, typically 600 grit and higher, leave scratches that are extremely shallow. These are often called polishing grits. They are used to refine the surface after coarser grits have done the main work.

Highly polished metal after fine grit sanding.

When you use sandpaper, you are essentially creating small scratches. Coarser grits create deeper, more visible scratches. Finer grits create shallower, less visible scratches. The term "won’t scratch" is a bit misleading. It’s more about the degree of scratching. If you want a mirror-like finish, you need to use a series of grits, ending with very high numbers. After using medium grits (like 120-220) to smooth the surface, you move to fine grits. Start with 320 or 400. Then go to 600, 800, 1000, or even higher. For polishing, you might use grits up to 2000 or 3000. These very fine grits are often used with water or oil. This is called wet sanding. Wet sanding helps keep the abrasive clean and reduces heat. It also helps produce a finer finish. Using high-quality abrasives, like those found in NOVOGRIT’s fine grit papers, ensures consistent scratch patterns. This makes it easier to move to the next grit. The scratches from a good quality 800 grit paper are uniform. This makes them easier to remove with 1000 grit. If the sandpaper is poor quality, the grit size might not be consistent. This can leave random deeper scratches that are hard to get out. For a truly scratch-free look (visually), you often follow sanding with polishing compounds. These compounds use even finer abrasives to buff the surface.

What Grade Sandpaper for Metal?

The term "grade" for sandpaper is often confusing. It usually refers to the grit size. Sometimes, it might also include terms like "fine," "medium," or "coarse." Understanding these terms helps you pick the right sandpaper for your metal project.

The "grade" of sandpaper for metal refers to its grit size. This tells you how many abrasive particles are on each square inch. Lower numbers mean coarser grit (bigger particles) and higher numbers mean finer grit (smaller particles). Coarse grades are for removing material, and fine grades are for smoothing and polishing.

Chart showing sandpaper grades for metal.

When someone asks about the "grade" of sandpaper for metal, they usually want to know the grit number. Here’s a general breakdown:

- Coarse Grades (40-80 grit): Used for heavy material removal. This includes taking off rust, paint, deep scratches, or shaping metal edges. These leave noticeable scratches.

- Medium Grades (100-220 grit): Used for general sanding. They smooth surfaces after coarse sanding. They prepare metal for painting or other finishes where a perfectly smooth surface isn’t needed. They remove the deeper scratches from coarser grits.

- Fine Grades (240-400 grit): Used for final smoothing before painting or light polishing. They leave very fine scratches that are less visible. They prepare the surface for primer or topcoat.

- Very Fine Grades (600-1000 grit): Used for polishing metal to a semi-gloss or high-gloss finish. They remove fine scratches from previous steps. Often used with wet sanding.

- Extra Fine / Ultra Fine Grades (1200+ grit): Used for achieving a mirror finish or for polishing chrome and other reflective metals. These are the grits used in the final stages of polishing. NOVOGRIT offers a range of grits suitable for each stage of metal finishing. This helps ensure you have the right grade for every step of your project. Always start with the lowest grit needed to do the job. Then work your way up through the grits. Skipping steps can make it harder to get a smooth finish. You won’t remove the scratches from the previous, coarser grit effectively.

Conclusion

Choosing the right grit and type of sandpaper for metal is key to a successful project. Start coarse for removal and move to fine for smoothing and polishing. Brands like NOVOGRIT offer options suitable for every step.

You may also be interested in:

What is the difference between zirconium, ceramic, and aluminum oxide abrasives?

Choosing the right abrasive can be confusing. Using the wrong one wastes time, ruins your workpiece, and costs you money. Let’s make the choice simple for you. The main difference

Best Sandpaper for Aluminum: NOVOGRIT's Guide to Flawless Finishes

What is the Best Type of Sandpaper to Use on Aluminum? Do you find yourself frustrated by sandpaper that gums up instantly when you try to smooth aluminum? It is

Best Sandpaper for Paint Removal: Grits, Types, & Tips | NOVOGRIT

What is the Best Sandpaper for Removing Paint? Are you tired of staring at chipped, peeling paint on your furniture, walls, or even your car? It's a common problem, and

Automotive Wet Sanding: Supplies, Liquids & Best Sandpaper

Automotive Wet Sanding Supplies: What Do You Really Need? Wet sanding is a crucial technique in automotive refinishing, used to achieve a flawlessly smooth surface before painting or polishing. Unlike

Best Sandpaper for Paint Removal & Grit Guide

What Is the Best Sandpaper for Removing Paint? Removing old paint can be a tedious job, but using the right sandpaper makes all the difference. It's not just about grit;

Hardwood Floor Sanding: Screen vs. Sandpaper & Best Practices

Sanding Screen vs. Sandpaper for Hardwood Floors: Which is Best? When you're tackling hardwood floor projects, choosing the right abrasive is crucial for achieving a smooth, professional finish. Both sanding

Paper Backing vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper Back vs. Mesh Sanding Discs: Which One Should You Pick? Choosing the right sanding disc backing can significantly impact your project's efficiency and finish quality. Paper-backed discs are a

Sanding Mesh vs Paper: Which is More Economical and Better?

Is Sanding Mesh More Economical Than Sandpaper? Comparing Abrasive Costs When stocking up on abrasives, cost is always a factor. Paper sandpaper has traditionally been the standard, but newer mesh

Sanding Nets & Screens Use Cases: When to Choose Mesh Abrasives

Sanding Nets and Screens: What Are Their Best Use Cases? When you encounter sanding nets or screens, you might wonder where they fit into your sanding projects. Unlike traditional solid-backed