How to Choose Abrasive Manufacturers: Finding the Right Partner

Choosing the right abrasive manufacturer is crucial whether you’re a distributor, a hardware store owner, or a large industrial user. The quality of abrasives directly impacts your work or your customers’ results.

Choosing an abrasive manufacturer involves evaluating their product range, manufacturing quality, R&D capabilities, consistency, pricing, and customer service. It is essential to find a partner who can consistently supply high-quality abrasives that meet your specific needs.

Selecting a reliable abrasive manufacturing partner.

Making the right choice ensures you get reliable products, good value, and consistent supply, which is key for both profitability and performance.

How is the Abrasive Type Chosen for a Grinding Operation?

Abrasives come in many forms and types of grains. How do professionals decide which abrasive is right for a specific grinding task?

The type of abrasive chosen for a grinding operation depends primarily on the material being ground, the desired finish, the amount of material to be removed, and the specific grinding equipment being used. Different abrasive grains and backing materials are suited for different applications.

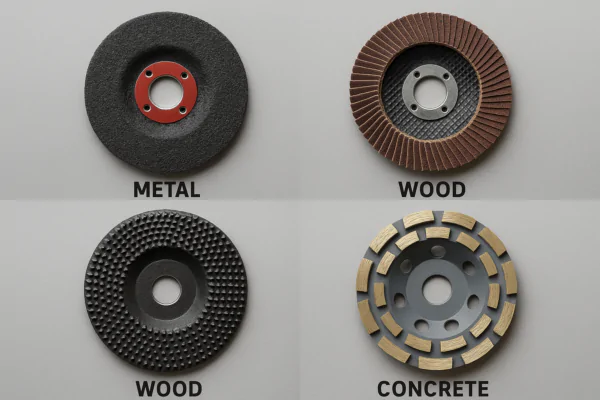

Various abrasive products for different materials.

For grinding operations, the material’s hardness is a major factor. Harder materials, like tool steel or stainless steel, often require tougher and sharper abrasives like ceramic alumina or silicon carbide. Softer materials, like aluminum or mild steel, can often be effectively ground with aluminum oxide. The amount of material to be removed also dictates the choice. For heavy stock removal, coarser grit sizes and tougher abrasive grains are necessary. For fine finishing or polishing, much finer grits are used. The desired finish is another critical consideration. Grinding for a rough surface to prepare for welding is very different from grinding to a smooth finish before painting. The type of equipment used (e.g., angle grinder, bench grinder, surface grinder) also influences the form of the abrasive (grinding wheel, flap disc, sanding disc, belt) and the recommended abrasive type. For example, when using flap discs for grinding on metal, the choice between aluminum oxide, zirconium alumina, or ceramic alumina will depend on the aggression needed and the lifespan desired on tough materials. Manufacturers like Hangzhou sharp Technology Co., Ltd., producing NOVOGRIT abrasives, offer a range of products with different abrasive types and backings designed for specific grinding and sanding applications on various materials, helping users select the optimal abrasive for their task. Understanding these factors is essential for efficient and effective grinding.

What are the two 2 main types of manufactured abrasive grains used for abrasive papers?

When you look closely at sandpaper, you see tiny particles. What are the most common types of these man-made abrasive particles?

The two main types of manufactured abrasive grains used for abrasive papers are Aluminum Oxide and Silicon Carbide. These synthetic materials are widely used due to their hardness, consistency, and ability to be produced in various grit sizes.

Comparing aluminum oxide and silicon carbide grains.

Let’s look at each type:

-

Aluminum Oxide (Al₂O₃): This is the most common and versatile abrasive grain. It is tough, durable, and suitable for a wide range of materials, including wood, metal (especially ferrous metals), plastics, and painted surfaces. Aluminum oxide grains fracture during use, creating new sharp cutting edges, which helps the sandpaper maintain its cutting ability. It’s often reddish-brown, brown, or white. Its cost-effectiveness and broad applicability make it a staple in abrasive papers for general purpose sanding.

-

Silicon Carbide (SiC): This is a harder and sharper abrasive than aluminum oxide. It’s characterized by its sharp, angular grains. Silicon carbide is excellent for sanding very hard materials like stone, glass, ceramics, and non-ferrous metals like aluminum and brass. It’s also commonly used for wet sanding applications, especially in automotive refinishing, as the grains are very brittle and fracture easily to expose new edges. Silicon carbide sandpaper is typically black or dark gray. Its sharpness makes it effective for fine finishing where a smooth surface is required.

While there are other manufactured abrasives like Zirconia Alumina and Ceramic Alumina which are used in more aggressive applications (like belts and grinding wheels), Aluminum Oxide and Silicon Carbide are the workhorses found in the vast majority of abrasive papers or sandpaper sheets and discs used for everyday tasks. Manufacturers like NOVOGRIT utilize both types of grains in their product lines to cater to different sanding requirements.

What is the Future of the Abrasive Industry?

Industries and materials are constantly evolving. How will the abrasive industry adapt and what trends are likely to shape its future?

The future of the abrasive industry is being shaped by advancements in materials science, automation, and sustainability. Key trends include the development of more advanced and specialized abrasive grains (like engineered ceramics), smarter and more efficient abrasive tools and processes, and increased focus on environmentally friendly manufacturing and products.

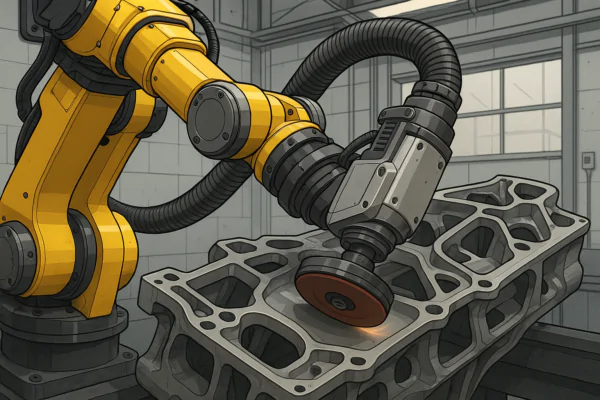

Robotic arm using abrasives in a manufacturing setting.

One major area of development is in the abrasive grains themselves. While aluminum oxide and silicon carbide remain important, there is increasing research into engineered ceramic abrasives that offer superior toughness, longer life, and more consistent performance, especially on challenging materials or in demanding automated applications. These new grains are designed to micro-fracture in a controlled way, continuously exposing fresh cutting points. Another significant trend is automation and robotics. As manufacturing becomes more automated, there’s a need for abrasives that work efficiently with robotic systems, including things like automated tool changing, consistent wear rates, and dust management integration. This drives innovation in the physical form and backing of abrasives. Sustainability is also becoming more important. Manufacturers are exploring ways to reduce waste in production, use recycled materials in backings, and develop dust extraction systems that capture and manage sanding debris more effectively. There is also a move towards developing abrasives that last longer, reducing the consumption of materials and the generation of waste. Finally, there is a growing need for specialized abrasives tailored for very specific applications in industries like aerospace, medical devices, and electronics, requiring incredibly tight tolerances and precise finishes. Companies like Hangzhou sharp Technology Co., Ltd. are investing in R&D to stay ahead of these trends, developing next-generation abrasives under brands like NOVOGRIT that meet the evolving needs of modern industries and applications.

How do Manufacturers Strengthen Abrasive Wheels?

Grinding wheels, especially those used with angle grinders, spin at very high speeds and are subjected to significant forces. How do manufacturers ensure they don’t shatter during use?

Manufacturers strengthen abrasive wheels by using reinforcing materials within the wheel’s structure and carefully controlling the bonding process of the abrasive grains and resin. Fiberglass mesh is commonly used as a reinforcing layer to add tensile strength and prevent fragmentation during operation.

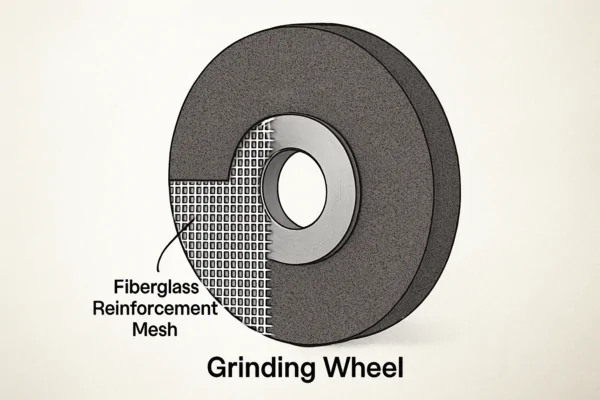

Cross-section of a grinding wheel showing reinforcement.

Abrasive grinding wheels are typically made by mixing abrasive grains with a bonding agent, usually a phenolic resin, and then molding this mixture into the desired wheel shape. This "green" wheel is then cured at high temperatures to harden the resin and create a solid structure. To prevent the wheel from breaking apart under the centrifugal forces of high-speed rotation or impact during use, layers of fiberglass mesh are embedded within the abrasive and resin matrix during the molding process. For cut-off wheels, there are usually two or three layers of mesh, strategically placed to provide maximum strength. For grinding wheels, the reinforcement might be slightly different but still designed to hold the wheel together. The quality and placement of this fiberglass reinforcement are critical safety features. Manufacturers also carefully control the density and homogeneity of the wheel material during pressing and curing to eliminate weak spots. Each wheel is typically tested for rotational speed and sometimes undergoes break-strength tests. The bond type (vitrified, resinoid, rubber, etc.) and its strength also play a significant role in the wheel’s integrity. Using high-quality resins and ensuring proper curing ensures that the bond is strong enough to hold the abrasive grains securely and withstand the stresses of grinding. Reliable manufacturers prioritize safety by incorporating robust reinforcement and rigorous testing procedures in their abrasive wheel production.

Conclusion

Choosing an abrasive manufacturer involves careful consideration of their capabilities and product quality. Understanding how abrasives are made, the types of grains used, and the innovations shaping the future of the industry helps in making informed decisions for your specific needs, whether it’s for general sanding or heavy-duty grinding with products like those from NOVOGRIT.

You may also be interested in:

What is the difference between zirconium, ceramic, and aluminum oxide abrasives?

Choosing the right abrasive can be confusing. Using the wrong one wastes time, ruins your workpiece, and costs you money. Let’s make the choice simple for you. The main difference

Best Sandpaper for Aluminum: NOVOGRIT's Guide to Flawless Finishes

What is the Best Type of Sandpaper to Use on Aluminum? Do you find yourself frustrated by sandpaper that gums up instantly when you try to smooth aluminum? It is

Best Sandpaper for Paint Removal: Grits, Types, & Tips | NOVOGRIT

What is the Best Sandpaper for Removing Paint? Are you tired of staring at chipped, peeling paint on your furniture, walls, or even your car? It's a common problem, and

Automotive Wet Sanding: Supplies, Liquids & Best Sandpaper

Automotive Wet Sanding Supplies: What Do You Really Need? Wet sanding is a crucial technique in automotive refinishing, used to achieve a flawlessly smooth surface before painting or polishing. Unlike

Best Sandpaper for Paint Removal & Grit Guide

What Is the Best Sandpaper for Removing Paint? Removing old paint can be a tedious job, but using the right sandpaper makes all the difference. It's not just about grit;

Hardwood Floor Sanding: Screen vs. Sandpaper & Best Practices

Sanding Screen vs. Sandpaper for Hardwood Floors: Which is Best? When you're tackling hardwood floor projects, choosing the right abrasive is crucial for achieving a smooth, professional finish. Both sanding

Paper Backing vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper Back vs. Mesh Sanding Discs: Which One Should You Pick? Choosing the right sanding disc backing can significantly impact your project's efficiency and finish quality. Paper-backed discs are a

Sanding Mesh vs Paper: Which is More Economical and Better?

Is Sanding Mesh More Economical Than Sandpaper? Comparing Abrasive Costs When stocking up on abrasives, cost is always a factor. Paper sandpaper has traditionally been the standard, but newer mesh

Sanding Nets & Screens Use Cases: When to Choose Mesh Abrasives

Sanding Nets and Screens: What Are Their Best Use Cases? When you encounter sanding nets or screens, you might wonder where they fit into your sanding projects. Unlike traditional solid-backed