What is the Best Sandpaper for Removing Paint?

Are you tired of staring at chipped, peeling paint on your furniture, walls, or even your car? It’s a common problem, and getting rid of old paint can feel like a daunting task. But what if I told you the right sandpaper could make all the difference, transforming a frustrating chore into a manageable project?

The best sandpaper for removing paint typically depends on the type of paint, the surface, and the desired finish. For heavy paint removal, coarser grits like 40-60 are ideal, while finer grits such as 80-120 help to smooth the surface afterward. Understanding grit levels is key to efficient and effective paint stripping.

Different sandpaper grits for paint removal.

Recently, I was working on restoring an old wooden chest that had layers of flaking varnish and paint. I started with a grit that was too fine, and it felt like I was getting nowhere fast. It truly showed me the importance of choosing the correct sandpaper from the outset. Throughout this article, I will explain how to pick the perfect sandpaper for your paint removal task. This will help you achieve the best results with less effort.

What Sandpaper is Best for Removing Paint?

Do you find yourself wondering which sandpaper to grab when faced with a paint removal project? Choosing the right grit can significantly impact your efficiency and the final outcome. Picking the wrong one can lead to frustration or even damage.

The best sandpaper for most paint removal jobs is a medium-to-coarse grit, typically ranging from 40 to 80. This range allows for effective material removal without being overly aggressive on the underlying surface. The type of abrasive material, such as aluminum oxide or silicon carbide, also plays a critical role in its performance on paint.

An orbital sander removes paint efficiently.

Selecting the best sandpaper for paint removal is not a one-size-fits-all situation. It depends heavily on the condition of the paint and the type of material you are working on. For instance, removing thick, stubborn layers of old paint from wood requires a different approach than lightly sanding a metal surface before a new coat. My company, Hangzhou sharp Technology Co., Ltd., has spent 15 years developing high-quality abrasives like our NOVOGRIT line. This has given me a deep understanding of how different sandpaper types perform in real-world applications.

-

Understanding Grit and Material:

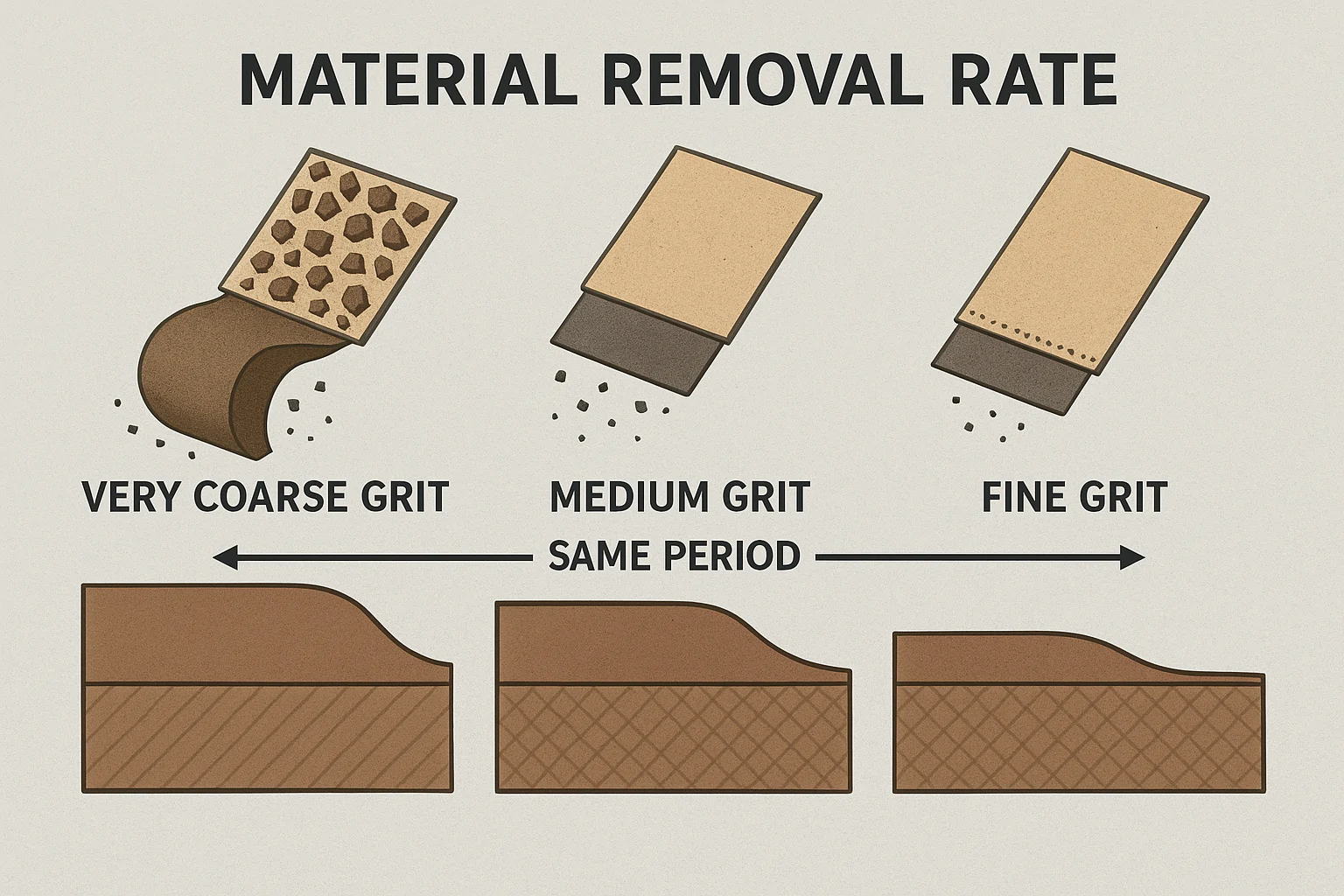

- Grit: Grit refers to the size of the abrasive particles on the sandpaper. A lower grit number means larger, coarser particles, which remove material more aggressively. A higher grit number means smaller, finer particles, which create a smoother finish.

- Abrasive Material: Common abrasive materials include aluminum oxide, silicon carbide, and zirconia alumina.

- Aluminum Oxide: This is a very common and versatile abrasive. It is durable and sharp, making it great for sanding wood, paint, and metal. It tends to fracture during use, creating new sharp edges. This feature helps it stay effective for longer. Many of our NOVOGRIT sanding discs use high-quality aluminum oxide, providing excellent cutting power and longevity for paint stripping.

- Silicon Carbide: This material is harder and sharper than aluminum oxide. It is ideal for very hard materials like stone, glass, and some metals. It is also good for wet sanding applications, as its sharp, brittle grains easily break apart to expose new cutting edges. However, it can be too aggressive for softer woods if you are not careful.

- Zirconia Alumina: This is a tough, durable abrasive that is well-suited for heavy material removal and aggressive sanding. Its self-sharpening properties make it ideal for demanding applications, such as sanding metals and hardwoods. It dissipates heat well, which helps prevent clogging when tackling thick paint layers.

-

Factors to Consider for Paint Removal:

| Factor | Consideration | Best Grit Range / Type | Why it Matters |

|---|---|---|---|

| Paint Condition | Is the paint cracked, peeling, or a thin, intact layer? | Coarse (40-60) for heavy; Medium (80-120) for light. | Old, flaky paint needs aggressive removal. Intact paint needs surface roughening for adhesion. |

| Surface Material | Is it wood, metal, plastic, or drywall? | Varies: Aluminum oxide for wood/paint; Silicon carbide for metal/harder surfaces. | Different materials have different hardnesses and properties. The wrong abrasive can damage the substrate or be ineffective. |

| Tool Used | Hand sanding, orbital sander, belt sander? | Adapts to tool. Discs for orbital; Belts for belt sanders. | Power tools can handle coarser grits more effectively and quickly. Hand sanding requires more finesse with finer grits for control. |

| Desired Finish | Are you repainting or want a bare, smooth surface? | Progress from coarse to fine (e.g., 40 -> 80 -> 120 -> 220). | Aggressive grits remove paint quickly but leave scratches. Finer grits are essential for smoothing the surface for subsequent coatings or a natural finish. |

| Paint Type | Latex, oil-based, enamel, epoxy? | Coarser grits for thicker, tougher paints. | Some paints, especially epoxies, are much harder and more resistant to sanding. They require more aggressive initial grits. |

Will 40 Grit Sandpaper Remove Paint?

Are you facing really stubborn, thick layers of old paint and wondering if 40-grit sandpaper is the answer? It certainly sounds aggressive, and you might worry about damaging the surface underneath. However, for certain situations, it might be exactly what you need.

Yes, 40-grit sandpaper will effectively remove paint, especially thick, stubborn layers or heavily flaking paint. It is a very coarse abrasive designed for aggressive material removal. While excellent for stripping large amounts of paint quickly, it will leave noticeable scratches and requires subsequent sanding with finer grits to smooth the surface.

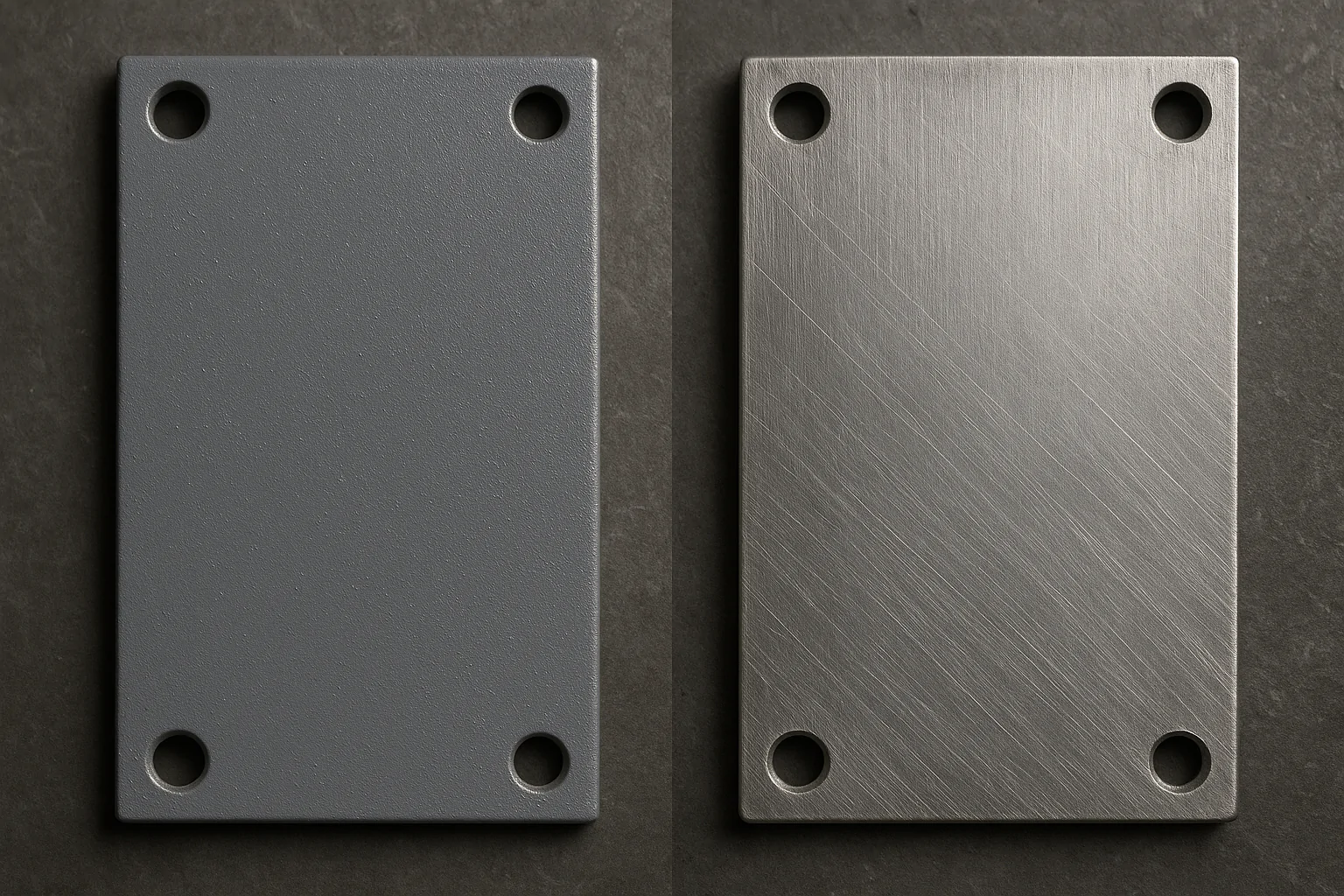

Coarse 40-grit sandpaper for aggressive removal.

When I first started in this industry, I was often hesitant to recommend something as coarse as 40-grit, fearing it would be too much. However, experience taught me its invaluable role in specific scenarios. Imagine a piece of furniture that has been painted over multiple times over decades, creating a thick, uneven coating. Or perhaps you are dealing with exterior house paint that has been exposed to the elements and is peeling severely. In these cases, a 40-grit sandpaper, like the robust options available in our NOVOGRIT heavy-duty series, becomes your best friend. It powers through those layers, saving you immense time and effort compared to trying to use a finer grit. However, it is crucial to remember that 40-grit is a "first pass" tool. Its primary job is to strip off the bulk of the material. It is not intended to leave a finished surface. The large abrasive particles will create deep scratch marks on the underlying material, whether it be wood, metal, or composite. Think of it as demolishing the old paint before you start the rebuilding process. You should always be prepared to follow up with at least 80-grit, then 120-grit, and possibly even higher, depending on the desired smoothness for your next step, such as priming or painting. Proper technique also helps. When using 40-grit, apply even, consistent pressure and keep your sander moving to avoid digging into one spot too deeply. Working in small sections and clearing away dust frequently also helps you see your progress and minimize re-sanding. For professional applications, especially in the automotive or furniture industries, where surfaces need to be perfectly smooth for optimal finishes like clear coats or lacquers, the progressive sanding steps are non-negotiable after using such a coarse grit.

Is 80-Grit Good for Removing Paint?

Are you wondering if 80-grit sandpaper strikes the right balance for your paint removal task? It is a common question. Many people know 40-grit is for heavy work, but 80-grit occupies a sweet spot that makes it incredibly versatile.

Yes, 80-grit sandpaper is very good for removing paint, often considered the most versatile choice for many projects. It is aggressive enough to strip moderate layers of paint quickly while leaving a more manageable scratch pattern than coarser grits. This makes it ideal for the initial removal of less stubborn paint or as a follow-up to 40-grit for surface refinement.

Effective paint removal with 80-grit sandpaper.

In my 15 years in the abrasives industry, I have seen 80-grit sandpaper earn its reputation as a true workhorse. It is usually the first grit I recommend for anyone tackling a less extreme paint removal job. If the paint is not excessively thick or heavily peeling, starting with 80-grit, particularly with a high-quality aluminum oxide abrasive like our NOVOGRIT sanding discs, can save you a lot of time. It avoids the deep gouges that finer grits often miss. It offers the perfect balance. It is aggressive enough to cut through paint efficiently, yet it is not so aggressive that it will severely damage the underlying surface. This makes it an excellent choice for scenarios where you need to remove paint without drastically altering the substrate, such as preparing an old cabinet for repainting or refreshing a metal railing. For example, when refinishing my old wooden patio chairs, the paint was chipped and faded, but not excessively thick. I started directly with 80-grit, and it stripped off the old paint beautifully without sanding away too much of the wood. The scratch pattern left by 80-grit is much finer than 40-grit. This means you will need fewer subsequent steps to achieve a smooth finish. After 80-grit, you can often jump directly to 120-grit, and then maybe 180-grit or 220-grit. This is an efficient progression for most repainting projects. Using 80-grit effectively means applying moderate pressure and letting the sandpaper do the work. Over-pressing can generate excessive heat and might cause premature wear or damage to the sandpaper and surface. It is also important to regularly clean the sandpaper or replace it. Paint can quickly clog the abrasive particles, reducing its effectiveness and making sanding more difficult. Our NOVOGRIT line is designed to resist clogging, which enhances its performance and lifespan, particularly when dealing with sticky paint residues.

What Grit Sandpaper Removes the Most?

Have you ever faced a paint removal project and wondered, "Which sandpaper grit will just get this done fastest?" It is a common thought, especially when dealing with layers that seem impossible to budge. Knowing which grit removes the most material is essential for efficiency.

The grit sandpaper that removes the most material is the lowest grit available, typically 40-grit or even 36-grit. These very coarse grits have the largest abrasive particles. This allows them to cut aggressively through thick layers of paint, rust, and other coatings very quickly. However, this aggressive removal comes at the cost of leaving very deep scratches on the surface.

Lowest grit sandpaper for maximum removal.

When I advise clients on heavy-duty applications, particularly in industrial settings where speed is critical, the discussion always turns to the absolute coarsest grits. For us at Hangzhou sharp Technology Co., Ltd., designing abrasives that can tackle extreme material removal is a core competency. Our NOVOGRIT line includes extremely coarse options specifically for these demanding tasks. While 40-grit is highly effective, grits like 36 or even 24 exist for truly exceptional removal needs, such as stripping heavy marine paint, automotive undercoating, or thick industrial epoxy. These grits contain large, widely spaced abrasive particles, which act like tiny planes gouging away material. They do not aim for a smooth finish in any sense, but rather for maximum penetration and material displacement. The trade-off, as mentioned, is the severe scratching they leave behind. Think of it like using a sledgehammer to demolish a wall – it gets the job done quickly, but you would not then try to paint over the rough rubble. You would need to refine the surface significantly afterward. Therefore, while these super coarse grits remove the most, they are only the starting point in a multi-stage sanding process. For example, if you are restoring a piece of antique machinery with layers of rust and old paint, starting with a 36-grit NOVOGRIT sanding belt on a belt sander would be the most efficient way to get to bare metal. After that, you would progressively move through 80-grit, 120-grit, and possibly higher to prepare the surface for priming and painting. It is crucial to have a clear plan for your subsequent sanding steps when opting for the raw power of the lowest grits. This ensures you achieve not just removal, but also the desired final surface quality. Always factor in the time and cost of these follow-up steps into your project plan.

Conclusion

Choosing the proper sandpaper grit for paint removal is crucial for both efficiency and success. Whether you need the aggressive power of a 40-grit or the versatility of an 80-grit, understanding the task and desired finish will guide your selection. Always remember to progress through finer grits to achieve a smooth, prepared surface for your next coating.

You may also be interested in:

What is the difference between zirconium, ceramic, and aluminum oxide abrasives?

Choosing the right abrasive can be confusing. Using the wrong one wastes time, ruins your workpiece, and costs you money. Let’s make the choice simple for you. The main difference

Best Sandpaper for Aluminum: NOVOGRIT's Guide to Flawless Finishes

What is the Best Type of Sandpaper to Use on Aluminum? Do you find yourself frustrated by sandpaper that gums up instantly when you try to smooth aluminum? It is

Automotive Wet Sanding: Supplies, Liquids & Best Sandpaper

Automotive Wet Sanding Supplies: What Do You Really Need? Wet sanding is a crucial technique in automotive refinishing, used to achieve a flawlessly smooth surface before painting or polishing. Unlike

Best Sandpaper for Paint Removal & Grit Guide

What Is the Best Sandpaper for Removing Paint? Removing old paint can be a tedious job, but using the right sandpaper makes all the difference. It's not just about grit;

Hardwood Floor Sanding: Screen vs. Sandpaper & Best Practices

Sanding Screen vs. Sandpaper for Hardwood Floors: Which is Best? When you're tackling hardwood floor projects, choosing the right abrasive is crucial for achieving a smooth, professional finish. Both sanding

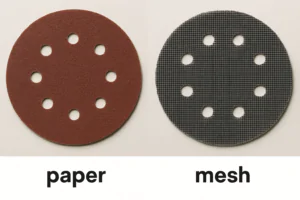

Paper Backing vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper Back vs. Mesh Sanding Discs: Which One Should You Pick? Choosing the right sanding disc backing can significantly impact your project's efficiency and finish quality. Paper-backed discs are a

Sanding Mesh vs Paper: Which is More Economical and Better?

Is Sanding Mesh More Economical Than Sandpaper? Comparing Abrasive Costs When stocking up on abrasives, cost is always a factor. Paper sandpaper has traditionally been the standard, but newer mesh

Sanding Nets & Screens Use Cases: When to Choose Mesh Abrasives

Sanding Nets and Screens: What Are Their Best Use Cases? When you encounter sanding nets or screens, you might wonder where they fit into your sanding projects. Unlike traditional solid-backed

Paper vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper vs. Mesh Sanding Discs: Which Should You Buy? Choosing the right abrasive disc is essential for efficient and effective sanding. Two primary types dominate the market: traditional paper-backed discs