Automotive Wet Sanding Supplies: What Do You Really Need?

Wet sanding is a crucial technique in automotive refinishing, used to achieve a flawlessly smooth surface before painting or polishing. Unlike dry sanding, it relies on a liquid medium to lubricate the abrasive and carry away sanding debris. But what exactly do you need to do it right?

For effective automotive wet sanding, essential supplies include high-quality, waterproof sandpaper specifically designed for wet applications, typically in progressively finer grits ranging from 800 to 3000 (or even higher for polishing). You will also need a lubricating liquid, most commonly water with a few drops of dish soap or a dedicated wet sanding lubricant, to reduce friction and flush away abraded particles. Other critical tools are a soft foam or rubber sanding block for even pressure, a spray bottle for consistent liquid application, and plenty of clean microfiber towels for wiping down the surface to inspect your progress and remove slurry.

Key supplies for automotive wet sanding.

Having the right gear makes a significant difference in achieving that mirror-like finish.

What should I wet sand my car with?

Understanding the purpose of wet sanding is key to choosing the right approach and materials for your car. What exactly are we trying to achieve, and with what?

You should wet sand your car to remove minor imperfections like orange peel, dust nibs, or light scratches in the clear coat before polishing, or to smooth out primer or base coat layers before applying the next coat. For this, you use very fine-grit waterproof sandpaper, typically starting around 800-grit and progressing incrementally to 1500-grit, 2000-grit, 2500-grit, or even 3000-grit. The goal is to create a uniformly dulled, finely scratched surface that can then be easily polished to a high-gloss finish, ensuring optical clarity and depth without damaging the underlying paint layers. Always use plenty of lubrication and a soft sanding block to ensure even pressure and prevent accidental deeper scratches.

The difference between a wet-sanded and polished car surface.

From my experience, wet sanding1 a car isn’t about removing large defects; it’s about refining the surface to perfection. When I’m working on a car, whether it’s after a fresh paint job to remove orange peel texture or to level out minor imperfections in the factory clear coat before a show-car polish, the process is always the same. I start with a relatively fine grit, usually 1500-grit2, unless there are deeper defects, in which case I might start with 1000 or 1200. I make sure to use a high-quality, flexible, waterproof sandpaper. I cut it into manageable pieces, usually quarters of a full sheet, and wrap it around a soft foam or rubber sanding block. The block is crucial because it distributes pressure evenly, preventing finger marks or uneven sanding that can lead to waves in the finish.

I consistently keep the surface and the sandpaper saturated with my lubricating liquid (usually water with a tiny bit of dish soap). This ensures the sandpaper glides smoothly, and the abraded clear coat particles are flushed away instead of building up and scratching the surface. I work in small sections, using gentle, even pressure, and move in straight, overlapping lines – either all in one direction or cross-hatching. After each grit, I thoroughly wipe down the area with a clean microfiber towel to inspect the work. I want to see a uniformly hazy, flat surface with no shiny spots (indicating areas I missed) and no deeper scratches from the previous grit. Only when I’m satisfied do I move to the next finer grit, like 2000, then 2500, and sometimes even 3000. This gradual progression ensures that the scratches from the previous grit are completely removed by the next, finer grit, leaving a perfectly refined surface ready for polishing. It’s a meticulous process, but the results are worth it for that deep, glossy finish. NOVOGRIT offers a fantastic range of wet sanding1 papers perfect for automotive work, from finer grits for clear coat refinement to coarser options for primer leveling.

What liquid do you use for wet sanding?

The choice of lubricant is critical for effective wet sanding. What is the standard, and are there any alternatives?

For wet sanding, the most common and effective liquid is plain water, often with a few drops of dish soap added. The soap acts as a surfactant, reducing the surface tension of the water, allowing it to spread more evenly, lubricate better, and help suspend the abraded particles, preventing them from clogging the sandpaper. Dedicated wet sanding lubricants are also available, which are formulated to provide optimal lubrication and particle suspension. While other liquids like WD-40 or kerosene are sometimes mentioned, they are generally not recommended for paint or clear coat as they can leave residues, potentially react with the finish, or make subsequent polishing difficult due to their oily nature.

Water with a touch of dish soap is an ideal wet sanding lubricant.

From my own garage experience, I’ve found that keeping it simple with the lubricating liquid is almost always best. My go-to is plain tap water, poured into a spray bottle, with just a couple of drops of a mild dish soap. And I mean a couple – too much soap creates excessive suds that can hinder visibility and make cleanup more difficult. The soap really does make a difference; you can feel the sandpaper glide much more smoothly over the surface compared to just plain water. It also helps the fine sanding dust stay suspended in the liquid, flushing it away rather than allowing it to clump up and cause deeper scratches.

I’ve experimented with dedicated wet sanding lubricants3, and while they perform excellently, for most DIY or even professional applications, the water-and-soap mixture is incredibly effective and much more cost-effective. I would strongly advise against using anything oily like WD-40 or other solvents. These can be absorbed by the paint or clear coat, potentially causing issues with adhesion if you’re repainting, or making it incredibly difficult to achieve a swirl-free, high-gloss finish when it comes time to polish. Any residue left behind by oily lubricants4 will also be a nightmare to clean off before polishing compounds can work effectively. Stick to water and a minimal amount of soap for the cleanest and most predictable results.

Is WD-40 good for wet sanding?

The use of WD-40 in wet sanding is a point of contention among detailers and refinishers. Let’s clarify its suitability.

No, WD-40 is generally not good for wet sanding, especially when working on automotive paint or clear coat. While it provides lubrication, its oily composition can cause several problems. It can leave a greasy residue on the surface that is difficult to remove completely, which can interfere with the adhesion of new paint or primer if you are not just polishing afterward. More importantly, its oily nature can make subsequent polishing steps much harder, as polishing compounds rely on friction and clean surfaces to break down effectively. Using WD-40 can lead to persistent hazing, difficulty removing swirl marks, or even paint defects if residues get trapped. Stick to water with a little soap or dedicated wet sanding lubricants for clean, predictable results.

[Insert image: A bottle of WD-40 with a "No" symbol over it, next to a wet-sanded car panel looking hazy from oil residue.]

Avoid using WD-40 for wet sanding automotive finishes.

I’ve heard people suggest WD-40 for wet sanding5, usually because it’s a common lubricant in many garages. But from my personal experience, and what I’ve learned from others in the automotive refinishing world, it’s a definite no-go for paint or clear coat. I once tried it on a small test panel, and while it felt incredibly slick, the aftermath was a nightmare. The panel felt greasy even after multiple rinses, and when I tried to polish it, the polishing compound just smeared around instead of breaking down. It was almost impossible to get rid of the hazing and achieve a truly clear, high-gloss finish. The residue just kept reappearing.

The problem is that paint and clear coat are porous, even if microscopic. Oily substances like WD-40 can penetrate these pores or leave a film that interferes with the chemical reaction of polishing compounds6. It can also create fisheyes or other adhesion issues if you’re planning on repainting over the sanded surface. For polishing paint, you want a perfectly clean, abraded surface. WD-40 contaminates that surface. There might be very niche applications for WD-40 with certain types of metal or rough industrial work, but for anything involving automotive paint, clear coat, or fine finishing, it’s best to keep WD-40 far away from your wet sanding5 process. Water with a dash of dish soap is simple, effective, and won’t cause you headaches down the line.

What sandpaper is best for wet sanding?

The abrasive material and backing of sandpaper are crucial for wet sanding. What specific types should you look for?

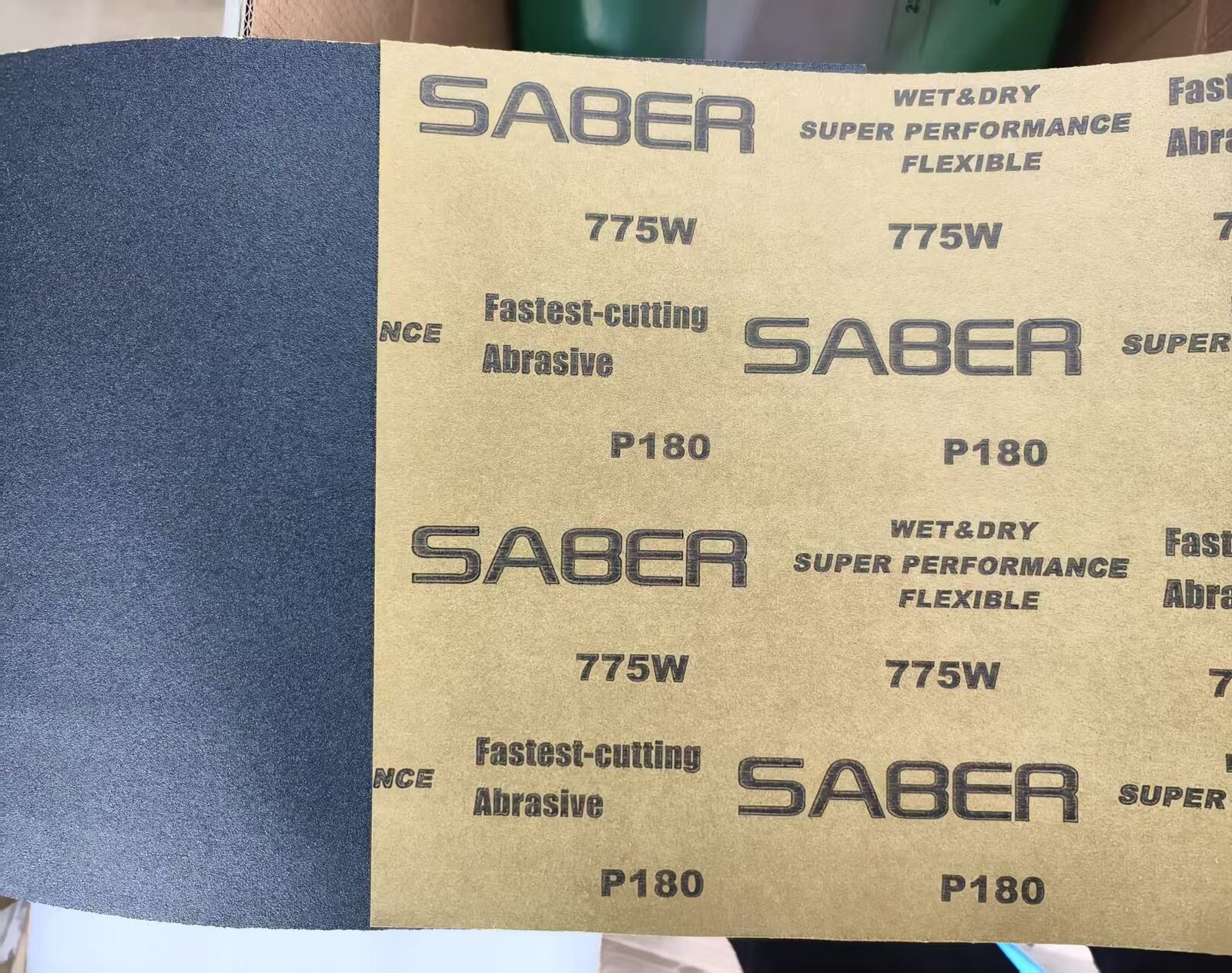

The best sandpaper for wet sanding is typically made with Silicon Carbide abrasive particles bonded to a waterproof backing. Silicon Carbide is extremely sharp and brittle, making it ideal for cutting through clear coats and primers efficiently without generating excessive heat, and its particles fracture to create new sharp edges, maintaining cutting action. The "waterproof" or "wet/dry" designation is crucial, meaning the paper backing and adhesive are designed to withstand immersion in liquid without disintegrating. Look for flexible paper or film-backed sandpaper that can conform to curves and is less prone to curling. NOVOGRIT offers a range of high-quality, durable, and waterproof Silicon Carbide sanding papers that perform exceptionally well for automotive wet sanding applications.

[Insert image: A piece of black wet/dry sandpaper with water droplets on it, showing its waterproof nature.]

Waterproof Silicon Carbide sandpaper is ideal for wet sanding.

When it comes to wet sanding, the type of sandpaper isn’t just a suggestion, it’s a requirement. I’ve made the mistake of trying to use regular dry sandpaper for wet sanding in a pinch, and it was a disaster. The paper quickly turned to mush, the abrasive fell off, and it was just a mess. That’s why you absolutely need "wet/dry" sandpaper. These papers are constructed with a special waterproof backing7 (often a heavy paper or a film) and waterproof resins to hold the abrasive grains.

For the abrasive itself, Silicon Carbide8 is almost universally preferred for wet sanding, especially on automotive finishes. Unlike Aluminum Oxide, which is tough and durable for dry sanding wood, Silicon Carbide8 is sharper and fractures more easily. This fracturing action is actually a good thing for wet sanding; it constantly exposes new, sharp cutting edges, preventing the paper from dulling too quickly. It also produces a very fine scratch pattern that’s easier to polish out. When I’m shopping for wet sanding paper, I always look for that "wet/dry" or "waterproof" label, and I prefer the feel of Silicon Carbide8. It gives me the confidence that the paper won’t break down mid-sanding and that I’ll achieve the precise, consistent scratch pattern needed for a perfect finish. NOVOGRIT’s expertise in abrasives shines in their wet sanding papers, offering excellent cutting ability and durability.

Conclusion

For automotive wet sanding, gather waterproof sandpaper (800-3000 grit), a sanding block, spray bottle, and microfiber towels. Wet sand your car with fine grits to refine clear coat imperfections before polishing, using water with a touch of dish soap as a lubricant. Avoid WD-40, as it can cause residue issues. Silicon Carbide wet/dry sandpaper is best due to its sharpness and waterproof properties.

-

Explore this link to learn expert techniques and tips for achieving a flawless finish through wet sanding. ↩ ↩

-

Discover the benefits of using 1500-grit sandpaper for wet sanding and how it contributes to a perfect finish. ↩

-

Learn about the performance of dedicated wet sanding lubricants and how they compare to DIY mixtures for optimal results. ↩

-

Understand the potential issues caused by oily lubricants in sanding and how they affect paint adhesion and finish quality. ↩

-

Explore this link to discover the most effective lubricants for wet sanding, ensuring a smooth and flawless finish without complications. ↩ ↩

-

Learn about polishing compounds and their role in achieving a high-gloss finish on automotive paint, enhancing your refinishing skills. ↩

-

Discover the significance of waterproof backing in sandpaper and how it enhances the sanding process for better results. ↩

-

Learn why Silicon Carbide is the go-to choice for wet sanding, especially in automotive finishes, and its benefits over other abrasives. ↩ ↩ ↩

You may also be interested in:

What is the difference between zirconium, ceramic, and aluminum oxide abrasives?

Choosing the right abrasive can be confusing. Using the wrong one wastes time, ruins your workpiece, and costs you money. Let’s make the choice simple for you. The main difference

Best Sandpaper for Aluminum: NOVOGRIT's Guide to Flawless Finishes

What is the Best Type of Sandpaper to Use on Aluminum? Do you find yourself frustrated by sandpaper that gums up instantly when you try to smooth aluminum? It is

Best Sandpaper for Paint Removal: Grits, Types, & Tips | NOVOGRIT

What is the Best Sandpaper for Removing Paint? Are you tired of staring at chipped, peeling paint on your furniture, walls, or even your car? It's a common problem, and

Best Sandpaper for Paint Removal & Grit Guide

What Is the Best Sandpaper for Removing Paint? Removing old paint can be a tedious job, but using the right sandpaper makes all the difference. It's not just about grit;

Hardwood Floor Sanding: Screen vs. Sandpaper & Best Practices

Sanding Screen vs. Sandpaper for Hardwood Floors: Which is Best? When you're tackling hardwood floor projects, choosing the right abrasive is crucial for achieving a smooth, professional finish. Both sanding

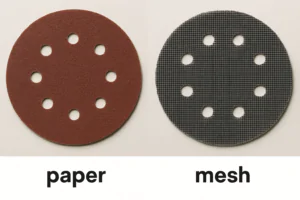

Paper Backing vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper Back vs. Mesh Sanding Discs: Which One Should You Pick? Choosing the right sanding disc backing can significantly impact your project's efficiency and finish quality. Paper-backed discs are a

Sanding Mesh vs Paper: Which is More Economical and Better?

Is Sanding Mesh More Economical Than Sandpaper? Comparing Abrasive Costs When stocking up on abrasives, cost is always a factor. Paper sandpaper has traditionally been the standard, but newer mesh

Sanding Nets & Screens Use Cases: When to Choose Mesh Abrasives

Sanding Nets and Screens: What Are Their Best Use Cases? When you encounter sanding nets or screens, you might wonder where they fit into your sanding projects. Unlike traditional solid-backed

Paper vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper vs. Mesh Sanding Discs: Which Should You Buy? Choosing the right abrasive disc is essential for efficient and effective sanding. Two primary types dominate the market: traditional paper-backed discs