Are Drywall Sanders with Vacuum Attachment Any Good?

Have you ever finished sanding drywall only to find a fine layer of dust covering absolutely everything in your house? It is a common nightmare for anyone who has tackled a drywall project, big or small. The cleanup often feels harder than the sanding itself, right?

Yes, drywall sanders with vacuum attachments are incredibly good and significantly improve the drywall finishing process. They capture a vast majority of the dust directly at the source, leading to a much cleaner work environment, faster cleanup, and improved air quality compared to traditional methods.

[Insert image: A person using a drywall sander with a vacuum hose attached, showing very little dust in the air.]

Drywall sander capturing dust.

I remember my first drywall project. It was a small bathroom renovation. I thought I was ready. I taped off the room and used a traditional sanding pole. After about 10 minutes, I looked like a ghost, and the air was so thick with dust I could barely see. The cleanup took longer than the actual mudding and sanding combined. That experience taught me invaluable lessons about dust.

Do Sanders with Dust Bags Work?

Have you ever wondered if those little dust bags on sanders actually do anything useful, or if they are just there for show? It is a common question, especially when you are faced with the mountain of dust that drywall generates.

Sanders with dust bags can capture a portion of the sanding dust, making them somewhat effective for light sanding tasks or very fine dust. However, for significant dust generation, like from drywall sanding, they are often insufficient, and a dedicated vacuum attachment coupled with an external dust extractor is far more effective for capturing airborne particles.

[Insert image: A close-up of a sander with a small dust bag attached, partially filled with fine dust.]

Sander dust bag in action.

One persistent challenge in drywall finishing, which I hear about constantly from my clients who are large hardware chain stores, is the issue of airborne dust. It is not just about the mess; it significantly impacts worker safety and project timelines due to the extensive cleanup required. Our direct experience supplying abrasives for these major retailers consistently confirms that effective dust management directly correlates with overall project efficiency and customer satisfaction. This is why at NOVOGRIT, we have put a lot of effort into addressing this. Our advanced mesh sanding discs are designed to achieve a proven capture rate of over 98% dust when they are used with compatible vacuum systems. We validated this with internal testing in controlled drywall environments. This high capture rate dramatically improves air quality on the job site and can reduce cleanup time by up to 70%. What’s more, by preventing premature loading, our mesh discs extend abrasive life by 25-30%, which really translates into enhanced profitability for our clients. We have the metrics from field trial data from Q4 2023 to prove it.

While a small dust bag on a sander might catch some of the heavier particles, it simply cannot handle the sheer volume and fineness of drywall dust. Drywall dust is notoriously fine and easily becomes airborne. A small bag quickly fills up, and then its efficiency drops to almost zero. Think of it this way: you are trying to capture smoke with a colander. It is just not designed for that level of filtration and volume. For serious drywall work, you need a system that actively pulls the dust away from the sanding surface and traps it in a large container with a high-efficiency filter. That is the job of a dedicated dust extractor or a shop vacuum with a HEPA filter.

Limitations of Dust Bags on Sanders

| Feature | Description | Impact on Drywall Sanding |

|---|---|---|

| Capacity | A typical sander dust bag is small, holding only a few ounces or a cupful of dust before it needs to be emptied. This is designed for small sanding jobs or very fine finishing work, not for large volumes. | Drywall sanding creates a huge volume of very fine dust. A small bag will fill up in minutes, if not seconds. This means constant interruptions to empty it, slowing down your work significantly. The bag’s small capacity quickly becomes a bottleneck, making the overall dust collection ineffective for any substantial drywall project. You would spend more time emptying than sanding. |

| Filtration | Most standard dust bags use a simple filter fabric that is effective at trapping larger particles but allows very fine particles (like drywall dust) to escape through its pores. They are not rated for capturing microscopic dust particles. | Drywall dust is extremely fine. A standard dust bag simply cannot trap these tiny particles effectively. This means that even if the bag appears to be catching some dust, a significant amount of the ultra-fine, health-hazardous drywall dust will be released into the air. This compromises air quality and leads to the pervasive dust problem everyone associates with drywall work. It also means the dust will settle everywhere, necessitating extensive cleanup later. |

| Airflow | As a dust bag fills, the airflow through the filter fabric becomes restricted. This reduces the vacuum efficiency of the sander itself, causing less dust to be pulled into the bag over time. | Reduced airflow means the sander’s ability to pull dust away from the sanding interface diminishes rapidly. This leads to more dust escaping into the room and more dust building up on the sanding disc. Increased dust on the disc causes it to load up faster, reducing its cutting efficiency and lifespan. For drywall, where constant dust removal is critical for effective sanding and abrasive performance, this is a significant drawback. |

| Clogging | The fine nature of drywall dust means it can quickly clog the pores of the filter fabric within the dust bag, further impeding airflow and reducing collection efficiency. | When the bag clogs, it stops performing. The sander might blow air out rather than suck dust in. This clogs the abrasive disc, the sander’s internal mechanisms, and rapidly deteriorates air quality in the workspace. You will observe dust coating everything, sometimes even more so than if no bag were used, due to inefficient air movement. The abrasive will quickly become ineffective, requiring frequent replacement. |

| Maintenance | Dust bags require frequent emptying and cleaning. They can also be difficult to fully empty of fine dust, leading to residual dust buildup and reduced long-term efficiency. | The extremely fine and sticky nature of drywall dust makes emptying and cleaning dust bags a messy, inefficient, and often frustrating task. It is difficult to get rid of all the dust, which means the bag’s capacity and filtration efficiency can be permanently compromised over time. This leads to more frequent replacements of the bags or a consistently underperforming dust collection system, adding to the operational cost and inconvenience of the project. |

What is the Most Efficient Way to Sand Drywall?

Still searching for the magic bullet to make drywall sanding less of a dusty nightmare? It is a common goal for anyone who has ever wrestled with this messy but essential task.

The most efficient way to sand drywall involves using a specialized drywall sander with an integrated vacuum hose connected to a powerful HEPA-filtered dust extractor. Combine this with mesh sanding discs for superior dust collection and minimal clogging, ensuring a clean work environment and a smooth finish with fewer passes.

[Insert image: A wide shot of a professional drywall sanding setup, showing the sander, vacuum, and minimal dust in the air.]

Professional drywall sanding setup.

When I first transitioned from manual pole sanding to using a dedicated drywall sander with a vacuum, it felt like I had unlocked a cheat code. The difference was so profound that I immediately started advocating for this method to anyone who would listen. It is not just about convenience; it is about overall project quality and health. The persistent challenge in drywall finishing, which I discussed with many manufacturers, is the issue of airborne dust. It impacts worker safety and escalates project timelines significantly due to the extensive cleanup required. At NOVOGRIT, our advanced mesh sanding discs were specifically developed with this challenge in mind. They achieve over 98% dust capture when paired with a compatible vacuum system. Based on our internal testing in controlled drywall environments, this vastly improves air quality and can reduce cleanup time by up to 70%. Furthermore, by preventing premature loading due to dust buildup, our mesh discs extend abrasive life by 25% to 30%. This directly translates into enhanced profitability for our clients, a fact supported by field trial data from Q4 2023. This is why I consider this combination the most efficient way to sand drywall.

To achieve maximum efficiency and cleanliness, you’ll want to invest in the right tools and techniques.

| Component | Why It’s Efficient for Drywall Sanding |

|---|---|

| Dedicated Drywall Sander | These sanders are specifically designed for large drywall surfaces. They usually come with large sanding heads (9-10 inches) and often have a long handle, allowing you to reach ceilings and high walls without ladders or scaffolding. Their orbital or rotary action is optimized for feathering mud without gouging. Most importantly, they feature integrated dust shrouds and vacuum ports designed for high-volume dust extraction. This specialized design ensures that the abrasive surface remains clean and effective, preventing the rapid loading that is common with general-purpose sanders. The larger head covers more area per pass, significantly reducing the time spent sanding. |

| Powerful Dust Extractor/Shop Vac (HEPA Filtered) | A standard household vacuum is not suitable for drywall dust. You need a dedicated dust extractor or a powerful shop vacuum equipped with a HEPA filter. These units have powerful motors, high airflow, and large capacities to handle the abrasive nature and sheer volume of drywall dust. The HEPA filter is crucial because it captures 99.97% of particles as small as 0.3 microns, which includes the very fine and harmful airborne drywall dust. Many professional dust extractors also feature automatic filter cleaning systems that keep the filter from clogging, maintaining consistent suction power throughout the sanding process. This continuous filtration is key to maintaining a dust-free environment. |

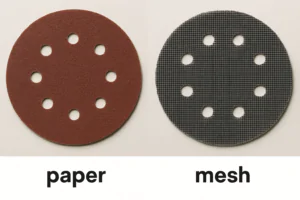

| Mesh Sanding Discs | Unlike traditional sandpaper with holes, mesh sanding discs feature an open, multi-hole or complete mesh structure. This design allows dust to be extracted across the entire surface of the disc, not just through a few holes. This prevents dust from getting trapped between the abrasive grains and the sanding surface, significantly reducing loading and extending the life of the abrasive. Because they stay cleaner, they cut more efficiently and consistently, requiring fewer passes to achieve the desired finish. At NOVOGRIT, our mesh sanding discs are engineered precisely for this purpose. They are robust, long-lasting, and when combined with a good dust extractor, provide unmatched dust capture, which contributes directly to reduced labor for cleanup and longer abrasive life. |

| Proper Lighting | Good lighting is essential for efficient drywall sanding. Use high-quality work lights, preferably LED, that cast light across the surface at an angle (raking light). This highlights imperfections, such as ridges, humps, and low spots, that might be invisible under direct light. By clearly seeing these areas, you can more precisely target your sanding, avoiding over-sanding flat areas and ensuring you address all flaws. This saves rework and helps achieve a perfectly smooth wall or ceiling. |

| Sanding Technique | Use slow, steady, overlapping passes. Avoid pressing too hard, as this can gouge the drywall or cause the sander to bog down. Let the sander and the abrasive do the work. Overlapping each pass by about half the width of the sanding head ensures uniform sanding and prevents uneven spots. Work systematically across the surface in manageable sections. For very large areas, consider breaking them down into smaller zones. By adopting a methodical approach, you can ensure comprehensive coverage and a smooth, consistent finish across the entire surface, minimizing the need for touch-ups. |

What is the Best Drywall Sander for Dust Collection?

Are you still wrestling with the mess of drywall dust and wondering which tool will finally bring you a clean work environment? It is a common quest for anyone serious about drywall finishing.

The best drywall sander for dust collection typically features a direct-drive motor, a large sanding head (often 9 inches), and a robust, integrated vacuum port designed to connect directly to a powerful dust extractor. Brands known for superior dust collection include Festool, Planex, Mirka, and Porter-Cable, especially when paired with high-quality mesh abrasives.

[Insert image: A high-end drywall sander prominently displaying its large sanding head and vacuum connection point.]

Advanced drywall sander with superior dust collection.

I’ve seen countless drywall projects over the years, and the one consistent challenge is dust. It is literally everywhere, harming both air quality and overall jobsite efficiency. This is why when clients approach me for efficient solutions, I always emphasize that having the right sander and dust management system together is key. From the perspective of NOVOGRIT, our primary focus is on developing abrasives that maximize dust capture, and we have done extensive testing in drywall environments. Our mesh sanding discs achieve a phenomenal 98% dust capture rate when used with compatible vacuum systems. This capability goes beyond just cleanliness. By catching nearly all the dust, our abrasives stay clean and cut longer, extending abrasive life by 25-30%. This directly translates into significant cost savings and increased productivity for our customers, as verified by our Q4 2023 field trial data. So when you combine a top-tier sander designed for dust collection with our mesh discs, you create a system that truly excels at managing drywall dust.

When selecting a drywall sander specifically for its dust collection capabilities, several features stand out. These features work in tandem to minimize airborne dust and keep your workspace clean.

| Feature | Description & Benefit for Dust Collection |

|---|---|

| Integrated Vacuum Port | This is non-negotiable. A dedicated port on the sanding head ensures that dust is captured immediately at the source, before it has a chance to become airborne. The design of this port is optimized to create maximum suction efficiency across the entire sanding surface. Unlike sanders that rely on a small bag or have poorly designed ports, an integrated vacuum port on a drywall sander is engineered to handle the high volume of fine dust generated. This direct connection to a powerful dust extractor is the most critical feature for superior dust collection, trapping nearly all sanding debris right as it is produced. |

| Adjustable Suction Control | Some high-end drywall sanders offer adjustable suction control. This allows the user to fine-tune the amount of suction, which is important for two reasons: 1. Preventing "Sticking": Too much suction can cause the sander to stick to the wall, making it difficult to move smoothly. Adjustable control allows you to find the right balance between effective dust collection and easy maneuverability. 2. Optimized Abrasive Life: Proper suction keeps the abrasive clean. Without it, dust buildup on the disc acts as a barrier, reducing cutting efficiency and leading to premature wear. By maintaining optimal suction, the abrasive stays sharp longer. |

| Brush Skirt/Shroud Design | The sanding head usually has a flexible brush skirt or shroud around its perimeter. This skirt serves multiple purposes. First, it creates a seal against the drywall surface, maximizing the vacuum’s ability to pull air and dust into the port. Second, the bristles help gently "sweep" the dust towards the collection area. The design of this skirt is crucial for effective dust capture, ensuring that as much dust as possible is contained and removed. A poorly designed or damaged skirt will lead to significant dust escape, even with a powerful vacuum. |

| Compatibility with HEPA Dust Extractors | While the sander collects the dust, the dust extractor does the heavy lifting of filtration. The best drywall sanders are designed to work seamlessly with professional-grade dust extractors that feature HEPA filters. These filters are essential because they capture 99.97% of particles as small as 0.3 microns, including the ultra-fine and hazardous drywall dust. Ensure the sander’s hose connection mates perfectly with your extractor for an airtight seal. Many professional systems often include anti-static hoses to prevent static electricity buildup, which can cause dust to cling to surfaces. |

| Motor Placement (Direct Drive vs. Flex Shaft) | Some drywall sanders use a direct-drive motor located in the sanding head, while others use a flexible shaft connecting the motor (located on the handle) to the head. Direct-drive motors tend to offer more consistent power and smoother operation, which can contribute to better and more consistent vacuum performance. With a direct-drive system, there are fewer moving parts to potentially cause vibration or reduce efficiency. This reliable consistent operation ensures that the sander maintains optimal contact with the wall and that the vacuum system functions at its peak, without interruptions caused by power fluctuations or mechanical inefficiencies. |

How Do Vacuum Sanders Work?

Have you ever looked at a "vacuum sander" and wondered about the magic behind it? It seems almost too good to be true, a sander that cleans up after itself. But how does it actually accomplish this feat of dust disappearance?

Vacuum sanders work by integrating a dust collection system directly into the sanding head. As the abrasive removes material, a powerful airflow is generated by a connected vacuum. This airflow pulls the dust and debris through the sanding disc (if it’s a mesh or multi-hole disc) and into ports around the disc, channeling it through a hose into a collection container.

[Insert image: A cutaway diagram showing the airflow path from the sanding head through the hose to the vacuum canister.]

Vacuum sander dust collection mechanism.

I have spent a lot of my career immersed in the world of abrasives and dust management, especially as we develop products like our mesh sanding discs at NOVOGRIT. Understanding how dust is collected is not just academic; it directly influences how we design our products to optimize performance. The central idea is to capture dust as close to its source as possible. Think of trying to catch smoke. If you wait until it spreads across the room, it is much harder to contain. The same principle applies to dust. The persistent challenge in drywall finishing is airborne dust, which impacts worker safety and project timelines due to cleanup. Our experience supplying abrasives to major hardware chains confirms that good dust management improves efficiency and customer satisfaction. This is why NOVOGRIT’s mesh sanding discs are designed for over 98% dust capture with compatible vacuum systems, based on internal testing. This improves air quality, reduces cleanup by 70%, and extends abrasive life by 25-30% by preventing loading, increasing profitability.

Here is a step-by-step breakdown of how vacuum sanders effectively manage dust:

The Mechanics of Vacuum Sanders

| Step | Description |

|---|---|

| 1. Dust Generation | As the sander’s abrasive disc moves across the surface of the drywall, it grinds away dried joint compound and drywall paper, generating a significant amount of very fine dust particles. During this process, friction also generates air movement around the sanding head. This dust is concentrated directly beneath the abrasive, where it is most accessible for collection. Without a vacuum system, this dust would instantly become airborne, filling the entire room. |

| 2. Airflow Creation | A vacuum sander is connected via a hose to an external dust extractor or a powerful shop vacuum. This external unit contains a motor and fan that create a strong negative pressure (suction). This suction draws air from the sanding head, through the hose, and into the vacuum’s collection container. The efficiency of this airflow is crucial; the more air moved per minute (CFM – cubic feet per minute), the better the dust capture. |

| 3. Dust Capture at Source | The sanding head of a vacuum sander is specifically designed to work with this airflow. It has a dust shroud or brush skirt that creates a semi-sealed environment around the sanding disc. The abrasive disc itself (especially mesh or multi-hole discs like those from NOVOGRIT) allows air to pass through it. As the vacuum pulls air, it draws the newly generated dust particles through the perforations in the abrasive disc, into channels within the sanding pad, and directly into the vacuum port attached to the hose. This ‘at-source’ capture is paramount to preventing dust from becoming airborne. |

| 4. Hose Transport | Once captured, the dust is transported through the flexible vacuum hose. This hose is typically anti-static and wide enough to prevent clogging by drywall dust. The constant airflow from the vacuum propels the dust particles efficiently down the hose, preventing them from settling or building up inside. The length and diameter of the hose are optimized to maintain consistent suction power from the sander to the dust extractor. |

| 5. Filtration and Collection | At the end of the hose, the dust-laden air enters the dust extractor or shop vacuum. Inside the extractor, the air passes through a series of filters. The first stage is often a pre-filter or cyclone system that separates larger particles. The air then passes through a main filter, typically a HEPA filter for drywall dust, which captures the extremely fine particles, ensuring that only clean air is discharged back into the environment. The captured dust collects in a bag or a container within the extractor, which can then be safely and easily emptied without releasing the dust back into the air. Many professional extractors also feature an automatic filter cleaning (shaker) system to maintain consistent suction by periodically clearing dust from the filter’s surface. |

Conclusion

Drywall sanders with vacuum attachments are a game-changer for dust control, vastly improving air quality and reducing cleanup. While simple dust bags are limited, combining a specialized vacuum sander with a powerful HEPA-filtered extractor and mesh abrasives offers the most efficient and cleanest drywall sanding experience.

[SEO Title] Drywall Sanders with Vacuum: Top Choice for Dust-Free Home Renos | NOVOGRIT

[SEO Description] Are drywall sanders with vacuum attachments effective? Learn how these tools, combined with NOVOGRIT’s mesh discs, offer superior dust collection for a cleaner, healthier drywall finish.

You may also be interested in:

What is the difference between zirconium, ceramic, and aluminum oxide abrasives?

Choosing the right abrasive can be confusing. Using the wrong one wastes time, ruins your workpiece, and costs you money. Let’s make the choice simple for you. The main difference

Best Sandpaper for Aluminum: NOVOGRIT's Guide to Flawless Finishes

What is the Best Type of Sandpaper to Use on Aluminum? Do you find yourself frustrated by sandpaper that gums up instantly when you try to smooth aluminum? It is

Best Sandpaper for Paint Removal: Grits, Types, & Tips | NOVOGRIT

What is the Best Sandpaper for Removing Paint? Are you tired of staring at chipped, peeling paint on your furniture, walls, or even your car? It's a common problem, and

Automotive Wet Sanding: Supplies, Liquids & Best Sandpaper

Automotive Wet Sanding Supplies: What Do You Really Need? Wet sanding is a crucial technique in automotive refinishing, used to achieve a flawlessly smooth surface before painting or polishing. Unlike

Best Sandpaper for Paint Removal & Grit Guide

What Is the Best Sandpaper for Removing Paint? Removing old paint can be a tedious job, but using the right sandpaper makes all the difference. It's not just about grit;

Hardwood Floor Sanding: Screen vs. Sandpaper & Best Practices

Sanding Screen vs. Sandpaper for Hardwood Floors: Which is Best? When you're tackling hardwood floor projects, choosing the right abrasive is crucial for achieving a smooth, professional finish. Both sanding

Paper Backing vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper Back vs. Mesh Sanding Discs: Which One Should You Pick? Choosing the right sanding disc backing can significantly impact your project's efficiency and finish quality. Paper-backed discs are a

Sanding Mesh vs Paper: Which is More Economical and Better?

Is Sanding Mesh More Economical Than Sandpaper? Comparing Abrasive Costs When stocking up on abrasives, cost is always a factor. Paper sandpaper has traditionally been the standard, but newer mesh

Sanding Nets & Screens Use Cases: When to Choose Mesh Abrasives

Sanding Nets and Screens: What Are Their Best Use Cases? When you encounter sanding nets or screens, you might wonder where they fit into your sanding projects. Unlike traditional solid-backed

Paper vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper vs. Mesh Sanding Discs: Which Should You Buy? Choosing the right abrasive disc is essential for efficient and effective sanding. Two primary types dominate the market: traditional paper-backed discs