What is the difference between zirconium corundum abrasive and ceramic abrasive and aluminum oxide abrasive?

What is the difference between zirconium corundum abrasive and ceramic abrasive and aluminum oxide abrasive?

Confused by technical abrasive names like zirconium corundum, ceramic, and aluminum oxide? Do you need to know which one is right for your tough jobs? Let me explain the differences simply.

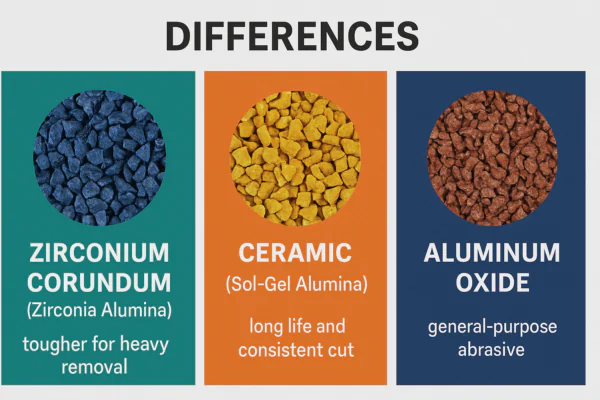

Aluminum Oxide is a general-purpose abrasive; Zirconium Corundum (Zirconia Alumina) is tougher for heavy removal; and Ceramic (Sol-Gel Alumina) is a high-tech grain offering long life and consistent cut.

Understanding these abrasive types is key to picking the right tool for your sanding. As someone who has supplied high-performance abrasives for 15 years, I know these names sound complex. But knowing what they mean helps you get the best results. Let’s break down each one.

Which is better zirconia or aluminum oxide abrasives?

Trying to pick the best abrasive for tough jobs feels like a puzzle? You need something strong that lasts but costs you right? Let’s look at two common types.

Zirconia Alumina abrasives generally last longer and cut faster than standard Aluminum Oxide, especially on metal and hard wood, making them better for heavy grinding and stock removal tasks.

Based on my work supplying abrasives, I see buyers ask this a lot. They work with metal or tough wood and need something that performs. It is not about "better" always, but "better for the job".

Understanding Aluminum Oxide vs. Zirconia Alumina

Let’s talk about Aluminum Oxide first. This is the most common abrasive grain. You find it on sandpaper, belts, and discs for many uses. It is good for general sanding on wood, paint, plastics, and some metals. It breaks down during use, which gives it new sharp edges. This works well, but it can wear out faster on very hard materials. Our company makes high-quality Aluminum Oxide abrasives that perform very well for many applications, perfect for furniture and automotive prep.

Now, Zirconia Alumina. This is a tougher, more durable grain. It is made differently than standard Aluminum Oxide. It has a unique self-sharpening ability. When you use it under pressure, tiny parts of the grain break off. This creates new, sharp points. This means the abrasive stays sharp for much longer than Aluminum Oxide, especially under high pressure and on hard materials. Zirconia Alumina is excellent for heavy stock removal, grinding welded seams, shaping metal, and working with very hard woods like oak or exotics. It costs more per disc or belt than Aluminum Oxide, but it can last many times longer on the right job. This saves time and money in the long run. We supply Zirconia Alumina belts and discs known for their performance in automotive body repair and metal fabrication.

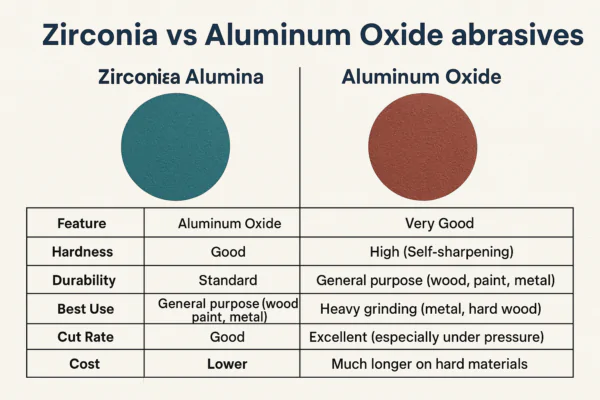

Here is a comparison:

| Feature | Aluminum Oxide | Zirconia Alumina |

|---|---|---|

| Hardness | Good | Very Good |

| Durability | Standard | High (Self-sharpening) |

| Best Use | General purpose (wood, paint, metal) | Heavy grinding (metal, hard wood) |

| Cut Rate | Good | Excellent (especially under pressure) |

| Cost | Lower | Higher |

| Lifespan | Standard | Much longer on hard materials |

Choosing between them depends on what you are sanding. For general woodworking or finishing, Aluminum Oxide is usually fine. For tough metal grinding or shaping hard materials fast, Zirconia Alumina is the better choice because it lasts longer and cuts more aggressively.

What is the difference between corundum and aluminum oxide?

Heard terms like "corundum" and "aluminum oxide" used for abrasives and felt confused? Do you wonder if they are the same thing or different? Let’s clear this up.

Corundum is the natural mineral form of aluminum oxide (Al₂O₃), while the aluminum oxide used in modern abrasives is typically synthetic, manufactured aluminum oxide designed for better performance.

When I discuss abrasive materials with buyers, sometimes these older terms come up. It is good to know the history, but more important to understand what you are actually buying today. My company uses high-grade materials.

Natural Corundum vs. Manufactured Aluminum Oxide

Corundum is found in nature. It is a mineral. Sapphire and Ruby are actually types of corundum with different impurities that give them color. Natural corundum is hard and has been used as an abrasive for centuries. However, natural deposits vary a lot in purity and crystal structure. This means their performance as an abrasive can be inconsistent. Some parts might be harder or sharper than others.

Today, almost all aluminum oxide used in modern sandpaper and other coated abrasives is synthetic. This means it is made by humans in a factory. The process involves heating bauxite (aluminum ore) in an electric arc furnace at very high temperatures. This process creates aluminum oxide crystals under controlled conditions. This synthetic aluminum oxide is much purer and has a more uniform crystal structure compared to natural corundum. This consistency is key for making high-performance abrasives. Because it is made in a controlled way, the hardness, toughness, and fracturing properties can be optimized for abrasive applications. It breaks down predictably during sanding, creating new sharp edges for consistent cutting.

So, while corundum is technically aluminum oxide, the stuff on your sandpaper is manufactured for a specific purpose. It is designed to cut well and last predictably. We use high-quality manufactured aluminum oxide in our standard abrasive products because it gives consistent, reliable performance that our buyers need. We even produce some raw materials ourselves to ensure this stable quality.

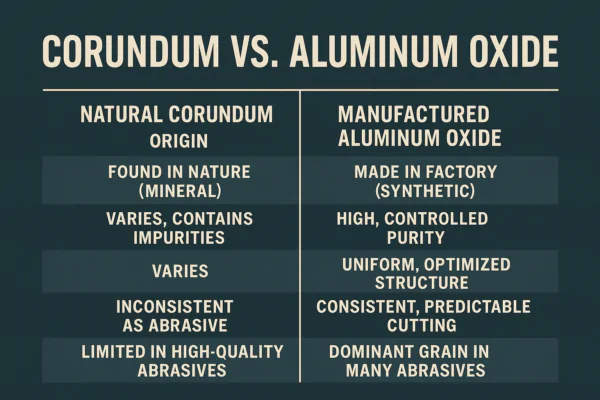

Here is the key difference:

| Feature | Natural Corundum | Manufactured Aluminum Oxide |

|---|---|---|

| Origin | Found in nature (mineral) | Made in factory (synthetic) |

| Purity | Varies, contains impurities | High, controlled purity |

| Crystal Structure | Varies | Uniform, optimized structure |

| Performance | Inconsistent as abrasive | Consistent, predictable cutting |

| Modern Use | Limited in high-quality abrasives | Dominant grain in many abrasives |

When you buy aluminum oxide abrasives from a good supplier like us, you are getting the manufactured type. This is what gives you reliable sanding results compared to the inconsistent performance you might get from natural corundum.

What is the difference between zirconium and ceramic?

Hearing about "zirconium" and "ceramic" abrasives makes your head spin? Do you wonder if these terms mean the same thing or point to different types of advanced abrasives? Let’s get this straight.

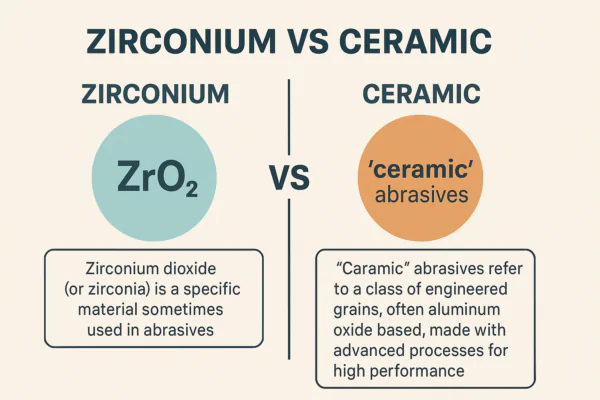

Zirconium dioxide (or zirconia) is a specific material sometimes used in abrasives, while "ceramic" abrasives refer to a class of engineered grains, often aluminum oxide based, made with advanced processes for high performance.

My buyers, especially in automotive and metalworking, ask about these high-tech abrasives. The names sound similar or confusing. It is like asking the difference between "steel" and "metal." Steel is a type of metal. Zirconia can be a component in some advanced grains, but "ceramic" describes a broader category based on how the grain is made.

Zirconium Dioxide (Zirconia) vs. Ceramic Abrasive Grains

Let’s start with Zirconium Dioxide (ZrO₂), commonly called Zirconia. This is a very hard and tough material. As we discussed earlier, Zirconia Alumina abrasive grains are a popular type of high-performance abrasive. These grains contain zirconium dioxide along with aluminum oxide. They are often made by fusing these materials together. They are known for their strength and ability to cut aggressively on hard metals.

Now, "Ceramic" abrasives. This term usually refers to a type of abrasive grain made using a special chemical process called the Sol-Gel process. This process allows engineers to grow very tiny, consistent aluminum oxide crystals. These crystals are then formed into abrasive grains. The key feature of these Sol-Gel ceramic grains is their microcrystalline structure and their self-sharpening property. When they are used, tiny parts of the grain break off, exposing new, sharp cutting edges. This happens at a much finer level than with traditional fused grains. Because of this microfracturing, ceramic abrasives (meaning Sol-Gel Aluminum Oxide) stay sharp for a very long time and offer a very high, consistent cut rate, especially on tough materials and in automated sanding applications.

So, Zirconium is a material (ZrO₂). Ceramic in the abrasive world usually means a specific type of grain (often Sol-Gel Aluminum Oxide) made with advanced technology, known for its unique self-sharpening. While some ceramic grains might incorporate zirconia, the term "ceramic abrasive" most commonly points to the advanced Sol-Gel Aluminum Oxide grain type. Our high-end abrasive cloth and belts use these advanced ceramic grains, giving them superior life and performance for demanding jobs in industries like automotive repair and metal finishing.

Here are the key points:

| Feature | Zirconium (as a material) | Ceramic (as an abrasive type) |

|---|---|---|

| What it is | A chemical compound (ZrO₂) | An engineered abrasive grain type |

| Manufacturing | Part of making Zirconia Alumina grains (often fused) | Made via Sol-Gel process (for Alumina) |

| Structure | Part of fused grain structure | Microcrystalline, very uniform |

| Key Property | Adds toughness (in Zirconia Alumina) | Microfracturing (self-sharpening) |

| Common Example | Used in Zirconia Alumina grains | Sol-Gel Aluminum Oxide grains |

Understanding this helps you choose the right high-performance abrasive. Zirconia Alumina is great for aggressive stock removal, while Ceramic (Sol-Gel Alumina) offers incredibly long life and consistent cut.

Which is better zirconia ceramic or alumina ceramic?

When looking at top-level abrasives, terms like "zirconia ceramic" and "alumina ceramic" sound very high-tech and confusing? You just need to know which one works best for your hardest jobs and gives you value? Let’s compare these advanced options.

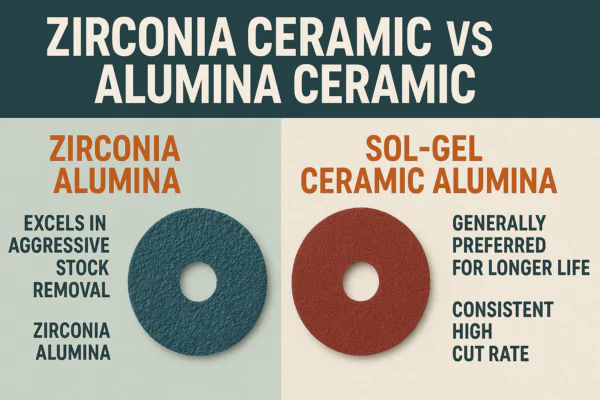

If "ceramic" refers to Sol-Gel Aluminum Oxide and "zirconia" refers to Zirconia Alumina (often fused), then Sol-Gel Ceramic Alumina is generally preferred for its longer life and consistent high cut rate, while Zirconia Alumina excels in aggressive stock removal.

This is a question I help buyers answer when they need the best performance for their specific application, like grinding heavy metal or dimensioning hardwood. The terms can be tricky, but the performance differences are real. My company provides both types in high-quality forms.

Comparing High-Performance Abrasive Grains

Let’s clarify the terms first, as they can be used differently. Usually, when people in the abrasive industry say "Ceramic abrasive," they mean the advanced Sol-Gel Aluminum Oxide grain. This grain is made using a special chemical process that creates a very fine, uniform crystal structure. Its main benefit is consistent microfracturing, which means it stays sharp for a very long time and keeps cutting at a high rate, even under moderate to high pressure. This makes it excellent for many applications, including sanding metal, hardwood, aerospace alloys, and for automated sanding where long life is key.

When someone says "Zirconia Ceramic" or just "Zirconia" in this context, they often mean the Zirconia Alumina grain (ZrO₂-Al₂O₃), which is typically made by fusing the two oxides together. While Zirconia Alumina is also a high-performance abrasive and is tougher than standard Aluminum Oxide, its self-sharpening mechanism is different from the fine microfracturing of Sol-Gel Ceramic. Zirconia Alumina grains tend to break off in larger pieces. This gives them a very aggressive initial cut, making them ideal for heavy material removal and rough grinding, especially on ferrous metals (steel, iron). However, they may not maintain their peak cut rate as consistently or last quite as long as Sol-Gel Ceramic Aluminum Oxide in some applications, particularly where finer finishes or extremely long life are needed.

So, if "Alumina Ceramic" means Sol-Gel Aluminum Oxide, and "Zirconia" refers to Zirconia Alumina, they serve slightly different purposes. Sol-Gel Ceramic (Alumina) is the go-to for maximum lifespan and consistent high performance on many materials. Zirconia Alumina is excellent when you need maximum aggression to remove a lot of material quickly. Our high-end abrasive cloth and belts leverage the strengths of both types, using advanced Sol-Gel Ceramics for products needing extreme life and consistent finish, and high-quality Zirconia Alumina for aggressive stock removal applications, tailored for demanding furniture and automotive sectors.

Here is a summary of these two high-performance types:

| Feature | Sol-Gel Ceramic Aluminum Oxide ("Ceramic") | Fused Zirconia Alumina ("Zirconia") |

|---|---|---|

| Manufacturing | Sol-Gel process | Fused process |

| Key Property | Fine Microfracturing (long life, consistent cut) | Macrofracturing (aggressive cut) |

| Cut Rate | High, very consistent | Very high initially, may drop faster |

| Lifespan | Excellent, very long | Very good, longer than standard AlO |

| Best Application | Long life, consistent finish, automated sanding, hard materials | Heavy stock removal, aggressive grinding on metal |

| Cost | Higher | High |

Choosing between them depends on whether your priority is maximum aggressive cut (Zirconia Alumina) or longest life and consistent cut rate (Sol-Gel Ceramic Alumina).

Conclusion

Choosing sandpaper involves grit and abrasive type. Understand Aluminum Oxide, Zirconia Alumina, and advanced Ceramic grains to get the best results for your work.

You may also be interested in:

What is the difference between zirconium, ceramic, and aluminum oxide abrasives?

Choosing the right abrasive can be confusing. Using the wrong one wastes time, ruins your workpiece, and costs you money. Let’s make the choice simple for you. The main difference

Best Sandpaper for Aluminum: NOVOGRIT's Guide to Flawless Finishes

What is the Best Type of Sandpaper to Use on Aluminum? Do you find yourself frustrated by sandpaper that gums up instantly when you try to smooth aluminum? It is

Best Sandpaper for Paint Removal: Grits, Types, & Tips | NOVOGRIT

What is the Best Sandpaper for Removing Paint? Are you tired of staring at chipped, peeling paint on your furniture, walls, or even your car? It's a common problem, and

Automotive Wet Sanding: Supplies, Liquids & Best Sandpaper

Automotive Wet Sanding Supplies: What Do You Really Need? Wet sanding is a crucial technique in automotive refinishing, used to achieve a flawlessly smooth surface before painting or polishing. Unlike

Best Sandpaper for Paint Removal & Grit Guide

What Is the Best Sandpaper for Removing Paint? Removing old paint can be a tedious job, but using the right sandpaper makes all the difference. It's not just about grit;

Hardwood Floor Sanding: Screen vs. Sandpaper & Best Practices

Sanding Screen vs. Sandpaper for Hardwood Floors: Which is Best? When you're tackling hardwood floor projects, choosing the right abrasive is crucial for achieving a smooth, professional finish. Both sanding

Paper Backing vs. Mesh Sanding Discs: Which Abrasive to Choose?

Paper Back vs. Mesh Sanding Discs: Which One Should You Pick? Choosing the right sanding disc backing can significantly impact your project's efficiency and finish quality. Paper-backed discs are a

Sanding Mesh vs Paper: Which is More Economical and Better?

Is Sanding Mesh More Economical Than Sandpaper? Comparing Abrasive Costs When stocking up on abrasives, cost is always a factor. Paper sandpaper has traditionally been the standard, but newer mesh

Sanding Nets & Screens Use Cases: When to Choose Mesh Abrasives

Sanding Nets and Screens: What Are Their Best Use Cases? When you encounter sanding nets or screens, you might wonder where they fit into your sanding projects. Unlike traditional solid-backed